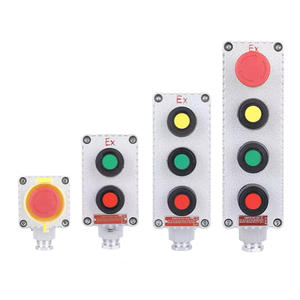

Push Button Control Switch Ip66

Top sponsor listing

Top sponsor listing

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/2

1/2

1/2

1/2

0

0

1/11

1/11

0

0

1/16

1/16

0

0

0

0

1/3

1/3

1/3

1/3

1/3

1/3

0

0

0

0

About push button control switch ip66

Understanding Push Button Control Switches

A push button control switch is a simple mechanical switch that connects or disconnects an electrical circuit when an operator presses the button [1]. These switches are fundamental in controlling machinery, appliances, and various electronic systems. The core function is to actuate an internal switching mechanism, allowing for the initiation or termination of a process [2].

The mechanism typically involves a spring that provides tactile feedback. When the button is pressed, the spring is compressed, causing electrical contacts to connect or disconnect. The spring then returns the button to its original position when released, unless the switch is designed to remain in the activated state [2].

Key Specifications and Features

When selecting a push button switch, several key specifications and features are crucial for ensuring it meets the requirements of your application.

-

Operation Type: Push button switches can be either momentary or maintained (latching) [2].

- Momentary: The switch only functions while the button is pressed. A spring returns it to its original position when released. This type is ideal for start/stop commands [2][8].

- Maintained (Latching): The switch remains in the activated state after being pressed until it is reset. This is suitable for power ON/OFF applications [2][8].

-

Electrical Contacts: The contacts are usually made from materials like silver alloy or gold-plated contacts to handle arcing and ensure reliable conductivity for various current and voltage levels [3][4][6].

-

Environmental Protection (IP Rating): The Ingress Protection (IP) rating is a critical specification for switches used in harsh environments. The "IP66" rating indicates that the switch is fully protected against dust ingress (the first digit "6") and high-pressure water jets from any direction (the second digit "6") [5][7]. This makes it suitable for outdoor, industrial, and marine applications where exposure to water and dust is a concern [5][7].

-

Durability: Industrial push buttons are engineered for millions of actuations. For example, some models can withstand up to 10 million operations, making them far more durable than consumer-grade switches [3][6].

-

Mounting and Design: The physical design of the switch can vary. For instance, flush-mount switches project only a few millimeters from the panel, providing a hygienic surface and reducing the risk of accidental activation [4]. The actuator (the part you press) can be flat, extended, or shaped like a mushroom for easy operation, especially when wearing gloves [1][3].

Applications of IP66 Push Button Switches

Push button switches with an IP66 rating are ideal for environments where dust and water exposure are significant concerns. Their robust protection makes them suitable for a wide range of industrial and commercial applications.

- Industrial Machinery: Used for start/stop controls, emergency stops, and machine safety shutdowns in factories, power plants, and utility substations [3][8].

- Outdoor and Marine Equipment: The waterproof nature of IP66 switches makes them perfect for outdoor control panels, construction equipment, and marine systems where they can be exposed to rain, sea spray, and high-pressure washdowns [4][5][7].

- Food and Beverage Processing: In environments where frequent cleaning with water jets is necessary, IP66 switches prevent dust and water ingress, ensuring hygiene and operational reliability [4][7].

- Public Infrastructure: Found in vending machines, self-service kiosks, and public transit ticketing machines, where they must withstand frequent use and potential vandalism [6].

Comparison of Push Button Switch Types

The table below compares different types of push button switches, highlighting their operation, typical applications, and environmental protection ratings.

| Type | Operation | Contacts | IP Rating | Applications |

|---|---|---|---|---|

| Momentary | Auto-reset | NO/NC | IP40-IP67 | Start signals, machine cycles |

| Maintained (Latching) | Latching | NO/NC | IP40-IP67 | Power ON/OFF, lighting circuits |

| Emergency Stop | Push-lock | NC | IP65+ | Machine safety shutdowns |

| Illuminated | Both | NO/NC | IP40-IP65 | Status indication panels |

| Key-Operated | Maintained | NO/NC | IP40-IP67 | Access control, elevators, cranes |

| Explosion-Proof | Both | NO/NC | ATEX/IECEx | Oil, gas, mining, chemical plants |

Table data sourced from [3].

Choosing the Right IP66 Push Button Switch

Selecting the appropriate push button switch involves considering several factors to ensure it meets the demands of your specific application.

- Environmental Conditions: The primary factor is the operating environment. If the switch will be exposed to dust, water jets, or harsh weather, an IP66 rating is essential [5][7].

- Functionality: Determine whether you need a momentary switch for temporary commands or a latching switch for maintaining a state. Also, consider if the switch needs to be illuminated for status indication [2][3].

- Durability and Standards: Look for switches that meet international standards like IEC 60947-5-1 for general control switches and IEC 60947-5-5 for emergency stop devices. Certifications such as UL, CE, and CCC ensure safety and reliability [3][8].

- Mounting and Design: Choose a switch with a mounting size that fits your panel (common sizes are 16mm, 22mm, and 30mm) and a design that suits the user interface, such as flush-mount for a sleek look or extended for gloved hands [4][7].

Market Trends and Suppliers

The market for push button switches is growing, with Asia Pacific projected to dominate due to rapid industrialization [8]. China has emerged as a major hub for manufacturing these switches, offering products that are often IEC and UL compliant at competitive prices [8]. Leading manufacturers include both international brands with local production, like ABB and Schneider Electric, and domestic OEM/ODM specialists that provide customized solutions [8].