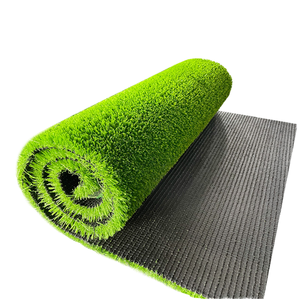

Putting Down Artificial Grass

About putting down artificial grass

Where to Find Suppliers for Putting Down Artificial Grass?

China remains the dominant hub for artificial grass manufacturing, with key production clusters in Hebei, Guangdong, and Langfang regions. These areas host vertically integrated facilities specializing in synthetic turf for sports, landscaping, and recreational applications. Hebei province, particularly around Xingtai and Anping, accounts for over 40% of China’s artificial grass output, supported by localized polymer processing and weaving infrastructure. The region benefits from proximity to raw material suppliers, reducing input costs by 15–20% compared to non-specialized manufacturing zones.

Facilities in these clusters typically operate automated tufting lines with UV-stabilized polyethylene (PE) and polypropylene (PP) yarn extrusion capabilities, enabling consistent pile density and durability. Production workflows include backing lamination, infill integration, and roll packaging, all optimized for export compliance. Buyers gain access to scalable operations capable of fulfilling orders ranging from sample-sized mats (1 m²) to large-scale installations exceeding 50,000 m². Lead times average 15–25 days for confirmed orders, with air or sea logistics coordinated through major ports like Tianjin and Shenzhen.

How to Choose Suppliers for Putting Down Artificial Grass?

Effective supplier selection requires verification across technical, operational, and transactional dimensions:

Material & Performance Specifications

Confirm fiber composition (PE/PP blend preferred for resilience), pile height (10–40 mm range standard for putting greens), and UV resistance ratings (≥5,000 hours tested). Request product test reports for colorfastness (ISO 105-B02), wear resistance (EN 13899), and water permeability. For golf-specific applications, verify roll width compatibility (typically 2m or 4m) and directional pile alignment to simulate natural ball roll.

Production Capacity and Customization

Assess supplier capabilities based on minimum order quantity (MOQ) thresholds and customization flexibility. Leading manufacturers support tailored solutions including:

- Custom pile height and density adjustments

- Color-matching for landscape integration

- Logo embedding via digital printing or cut-pile techniques

- Specialized backing systems for indoor/outdoor use

Suppliers with in-house extrusion and tufting lines can accommodate low-MOQ custom runs (as low as 50 m²), while high-volume producers require 500–1,000 m² minimums but offer lower unit pricing.

Quality Assurance and Transaction Security

Prioritize suppliers with documented quality control protocols, including batch testing and pre-shipment inspections. On-time delivery rates above 99%, response times under 2 hours, and participation in verified trade programs indicate reliability. Use secure payment methods with milestone-based disbursement, especially for first-time transactions. Sample validation is critical—request physical swatches to evaluate texture, backing integrity, and seam consistency before full procurement.

What Are the Top Suppliers for Putting Down Artificial Grass?

| Company Name | Location | Main Products | Price Range (USD/m²) | Min. Order | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Langfang Zhenti Artificial Lawn Co., Ltd. | Langfang, CN | Waterproof, high-density turf, 18–30mm pile | $1.20–1.50 | 1 m² | 99% | ≤2h | US $50,000+ | <15% |

| Hebei Heihe Commerce Co., Ltd. | Xingtai, CN | Golf putting greens, ornamental lawns, sports flooring | $0.88–3.66 | 50 m² | 100% | ≤1h | US $310,000+ | <15% |

| Guangdong Aojian Artificial Grass Ltd. | Foshan, CN | Synthetic turf pro series, mini putting mats | $1.99–9.99 | 500 m² | 66% | ≤2h | US $260,000+ | 33% |

| Dongguan Huati Sports Facilities Co., Ltd. | Dongguan, CN | Outdoor football turf, interlocking sports flooring | $13–15 | 500 m² | 100% | ≤2h | - | - |

| Guangzhou LYT Toys Co., Ltd. | Guangzhou, CN | Sports flooring, garden carpet, inflatable-integrated turf | $1.00–4.00 | 10 m² | 100% | ≤3h | US $130,000+ | 36% |

Performance Analysis

Hebei Heihe and Langfang Zhenti stand out for low MOQ accessibility and rapid responsiveness, making them ideal for prototyping or small-area installations. Hebei Heihe combines a 100% on-time delivery rate with competitive pricing starting at $0.88/m², suitable for budget-sensitive buyers. Guangdong Aojian offers premium-grade turf with wide customization options but exhibits a lower on-time performance (66%), indicating potential fulfillment risks despite strong reorder activity (33%). Dongguan Huati specializes in high-end sports applications with premium pricing ($13–15/m²), targeting commercial projects requiring certification-compliant surfaces. Guangzhou LYT provides flexible MOQs down to 10 m² and serves hybrid markets, though its core expertise spans beyond turf into recreational structures.

FAQs

How to verify artificial grass supplier reliability?

Cross-check delivery performance data with third-party sourcing platforms. Request evidence of material certifications (e.g., SGS REACH, UV resistance reports). Evaluate supplier responsiveness and technical clarity during inquiry stages as indicators of post-sale support capability.

What is the typical sampling timeline?

Standard samples are shipped within 7–10 days after confirmation. Complex customizations involving logo integration or unique pile configurations may require 15–20 days. Air freight adds 5–7 days for international delivery.

Can suppliers provide installation-ready artificial grass?

Yes, many manufacturers pre-cut rolls to specified dimensions and include seaming tape or joining clips. Some offer guidance documents or video tutorials for DIY laying procedures, including base preparation, adhesive application, and trimming protocols.

Do suppliers support private labeling and packaging?

Most suppliers listed offer OEM services, including custom packaging, branded labels, and graphic design integration. Minimum requirements vary—typically starting at 500 m² for full branding, though smaller runs may be accommodated at higher per-unit costs.

How does MOQ affect pricing and lead time?

Lower MOQs (1–50 m²) enable testing but carry higher unit prices. Bulk orders (≥500 m²) unlock volume discounts and more favorable terms, though they require longer production scheduling. Buyers should balance cost efficiency against inventory risk when determining order scale.