Python For Manufacturing Engineers

About python for manufacturing engineers

Where to Find Python for Manufacturing Engineers Equipment Suppliers?

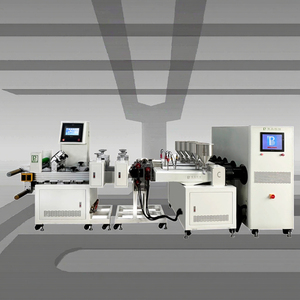

China leads in the production of industrial automation and manufacturing equipment integrated with Python-based control systems, with key supplier clusters located in Jiangsu, Henan, and Suzhou regions. These hubs combine advanced mechanical engineering expertise with software-driven process optimization, enabling manufacturers to deliver machinery equipped with Python-programmable logic controllers (PLCs) and data acquisition systems tailored for smart factory integration. The concentration of metallurgical, plastic processing, and woodworking machinery producers in these areas supports interoperability between hardware and open-source programming environments.

Industrial zones in Suzhou and Jiangsu host vertically integrated facilities capable of producing complete turnkey lines—from wire forming and extrusion systems to full-scale particle board production—with embedded Python scripting for real-time monitoring, predictive maintenance, and production analytics. This ecosystem enables suppliers to offer scalable solutions ranging from semi-automated units for small businesses to fully customized digital twin-ready systems. Buyers benefit from localized supply chains that reduce component lead times by 20–30%, while proximity to R&D centers ensures compatibility with Industry 4.0 frameworks such as OPC UA and MQTT protocols.

How to Choose Python for Manufacturing Engineers Equipment Suppliers?

Selecting qualified suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Integration Capability

Verify whether suppliers implement Python-compatible Human-Machine Interfaces (HMIs) or Supervisory Control and Data Acquisition (SCADA) systems. Request demonstration code or API access to assess scriptability for tasks like batch tracking, sensor calibration, or machine learning-based defect detection. For engineers deploying custom algorithms, confirm support for libraries such as NumPy, Pandas, or OpenCV within the controller environment.

Production Infrastructure Assessment

Evaluate core competencies through verifiable metrics:

- Facility size exceeding 5,000m² indicates capacity for large-scale assembly and testing

- In-house development teams specializing in both mechanical design and software integration

- Availability of PLCs programmable via Python (e.g., Raspberry Pi-based controllers, CODESYS with Python bridge, or PyControl frameworks)

Cross-reference on-time delivery performance (>95%) with response time (<4 hours) to gauge operational responsiveness.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services until equipment validation is completed post-delivery. Prioritize suppliers with documented quality management systems and export experience to North America, Europe, or Southeast Asia. Conduct sample testing to benchmark Python script execution accuracy under load conditions, particularly for time-sensitive control loops in high-speed manufacturing processes.

What Are the Best Python for Manufacturing Engineers Equipment Suppliers?

| Company Name | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Suzhou Hanxin Machinery Equipment Co., Ltd. | Metal forming, bending, welding machinery | 100% | ≤2h | <15% | $10,000+ | Limited | 1 piece/set | $2,500–7,500 |

| Suzhou Polytime Machinery Co., Ltd. | Pipe making, plastic extrusion lines | 100% | ≤2h | - | - | Standard configurations | 1 set | $28,000–580,000 |

| Henan Yugong Machinery Equipment Co., Ltd. | Egg tray packaging, manual/small business machines | 95% | ≤4h | 36% | $250,000+ | Color, material, size, logo, packaging | 1 set | $2,700–7,500 |

| Jiangsu Myworkes Equipment Co., Ltd. | PVC/PMMA/PET sheet extrusion lines | 100% | ≤21h | - | - | Configurable line layouts | 1 set | $50,000–90,000 |

| Linyi Yuequn International Trading Co., Ltd. | Wood-based panel production lines | 100% | ≤5h | 100% | $20,000+ | Full customization available | 1 set | $350,000–2,000,000 |

Performance Analysis

Suzhou-based suppliers demonstrate strong reliability with 100% on-time delivery and sub-2-hour response times, ideal for time-sensitive procurement cycles. Henan Yugong stands out with a 36% reorder rate, reflecting customer satisfaction in niche small-business automation segments. Linyi Yuequn exhibits exceptional retention (100% reorder rate), suggesting robust after-sales service and deep customization capabilities for engineered wood systems. Jiangsu Myworkes offers high-value plastic sheet lines but lags in communication speed, requiring proactive project management. High-end investments above $500,000 should include factory audits to verify software integration depth and Python runtime stability under industrial conditions.

FAQs

How to verify Python integration in manufacturing equipment?

Request access to the control system interface and inquire about supported scripting languages. Confirm whether Python scripts can interface directly with I/O modules, sensors, or vision systems. Ask for documentation on firmware update procedures and cybersecurity measures for network-connected controllers.

What is the typical lead time for Python-enabled machinery?

Standard models require 30–45 days for production and testing. Custom-developed systems with dedicated Python logic programming may take 60–90 days, depending on software validation complexity and hardware-software co-testing requirements.

Can these machines be integrated into existing factory networks?

Yes, most modern systems support Ethernet/IP, Modbus TCP, or PROFINET connectivity. Ensure the supplier provides SDKs or REST APIs compatible with Python-based enterprise dashboards or MES platforms for seamless data exchange.

Do suppliers offer remote diagnostics using Python?

Advanced suppliers deploy cloud-connected edge devices running Python daemons to collect vibration, temperature, and cycle time data. Remote troubleshooting is possible if the machine includes SSH access or secure web-based Jupyter terminals for live debugging.

How to negotiate customization with software functionality?

Submit detailed functional specifications including desired input/output variables, sampling frequency, alarm thresholds, and data logging intervals. Reputable vendors will provide a software requirement specification (SRS) document and prototype code snippets within 5–7 business days for review.