Rajkot Machine Price

About rajkot machine price

Where to Find Rajkot Machine Price Suppliers?

Manufacturers offering machinery at competitive price points associated with Rajkot are primarily based in China’s industrial hubs, particularly Zhengzhou and Changzhou, where mature supply chains for food processing, textile, and packaging equipment converge. These regions host vertically integrated production ecosystems that enable cost efficiency, rapid prototyping, and scalable output. While "Rajkot machine price" is often used as a search term by international buyers seeking budget-friendly industrial solutions—especially from India’s Rajkot region—the actual manufacturing base for these competitively priced machines is concentrated in East Asia.

Suppliers leverage localized component sourcing, automated assembly lines, and high-volume production to deliver machinery ranging from rice milling systems to embroidery and vending units at prices between $439 and $148,000. The clustering of engineering workshops, metal fabricators, and electronics integrators within 50km radii allows lead times averaging 20–35 days for standard configurations. Buyers benefit from modular designs that support customization while maintaining low per-unit costs, particularly for orders exceeding five sets.

How to Choose Rajkot Machine Price Suppliers?

Evaluating suppliers requires structured verification across technical, operational, and transactional dimensions:

Technical Capability Validation

Confirm whether the supplier offers machinery aligned with intended application specifications—such as grain processing capacity (kg/h), voltage compatibility (220V/380V), or automation level (semi-automatic vs. fully automatic). For food-grade machines, verify use of SUS304 stainless steel and compliance with hygiene standards. Although formal certifications (e.g., ISO 9001, CE) are not explicitly listed in available data, prioritize suppliers who provide detailed product specifications, operational manuals, and testing protocols.

Production and Customization Capacity

Assess scalability through key indicators:

- Facility size and workforce (inferred from online revenue and listing volume)

- Customization capabilities: color, material, logo, packaging, and graphic labeling options

- Diverse product portfolios indicating R&D investment (e.g., >50 listings in rice mills or snack machinery)

- Response time under 3 hours and on-time delivery rates exceeding 97%

Cross-reference product variety with specialization depth—suppliers like Zhengzhou Jawo Machinery Co., Ltd. list over 488 fruit & vegetable machines, suggesting niche expertise.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services to ensure funds are released only upon inspection clearance. Analyze reorder rates as a proxy for customer satisfaction: top-tier suppliers report reorder rates up to 37%. Request samples before bulk procurement to evaluate build quality, ease of operation, and after-sales documentation support. Lead times for sample shipments typically range from 7–14 days via express freight.

What Are the Best Rajkot Machine Price Suppliers?

| Company Name | Main Product Categories | Price Range (USD) | Min. Order | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Hento Machinery Co., Ltd. | Rice puffing, riveting, heat transfer machines | $439–3,599 | 1 set | 100% | 28% (first entity), 15% (second) | ≤1h | US $350,000+, $440,000+ | Color, material, size, logo, packaging, label, graphic |

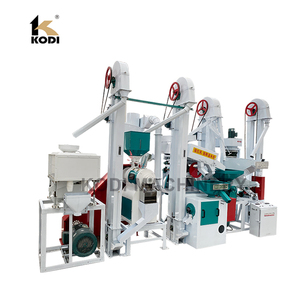

| Changzhou Kodi Machinery Co., Ltd. | Rice mill, drying, grinding equipment | $4,500–$148,000 | 1 set | 100% | - | ≤3h | - | Limited data; focus on core industrial models |

| Zhengzhou Jawo Machinery Co., Ltd. | Food processing, embroidery, rhinestone machines | $550–5,299 | 1 set | 100% | 37% | ≤5h | US $60,000+ | Implied through diverse listing types |

| smartime solution | Vending machines | $750–1,200 | 1 piece | - | - | ≤2h | - | No explicit customization noted |

Performance Analysis

Zhengzhou-based suppliers dominate responsiveness and repeat business, with Hento Machinery demonstrating strong service consistency (100% on-time delivery, sub-1h response) and mid-range pricing ideal for SMEs. Jawo Machinery stands out with a 37% reorder rate—the highest among listed vendors—indicating robust post-sale performance and reliability in food and textile machinery segments. Changzhou Kodi targets higher-end buyers with premium rice mill systems, including a $148,000 turnkey solution, though limited transaction metrics increase due diligence requirements. smartime solution focuses exclusively on vending machines with lower price entry points but lacks verifiable performance history.

FAQs

How to verify Rajkot machine price supplier reliability?

Analyze on-time delivery records, response speed, and reorder rates as proxies for operational stability. Request factory videos or virtual audits to confirm production infrastructure. Validate technical documentation, warranty terms, and availability of spare parts before placing orders.

What is the typical MOQ and lead time?

Minimum order quantity is generally 1 set across all suppliers. Standard lead times range from 20–35 days post-deposit, depending on machine complexity. Express production may reduce timelines by 5–10 days at additional cost.

Can I customize machinery specifications?

Yes, select suppliers offer customization in color, material, branding, and functional parameters. Zhengzhou Hento and Jawo Machinery explicitly list multiple customization fields. Submit detailed technical requests early in negotiations to assess feasibility and cost implications.

Do suppliers provide samples?

Sample availability depends on machine type and value. Lower-cost units (e.g., vending or bread-making machines) are more likely to be sampled at partial cost recovery. High-value systems (>$10,000) typically require site visits or video demonstrations instead.

Are there logistics and import considerations?

Yes. Confirm FOB or CIF shipping terms, container loading dimensions, and destination customs requirements—especially for electrical or food-contact machinery. Coordinate with freight forwarders to manage duties, certifications, and inland transport upon arrival.