Ram 32g Ddr4

1/4

1/4

1/11

1/11

1/1

1/1

1/2

1/2

1/6

1/6

1/1

1/1

1/2

1/2

1/3

1/3

1/2

1/2

1/19

1/19

1/2

1/2

1/11

1/11

1/3

1/3

About ram 32g ddr4

Where to Find RAM 32GB DDR4 Suppliers?

East Asia remains the central hub for DRAM and memory module manufacturing, with concentrated production ecosystems in China, South Korea, and Taiwan. China has rapidly expanded its semiconductor assembly and testing infrastructure, particularly in Jiangsu and Guangdong provinces, where integrated electronics industrial parks support high-volume memory module production. These regions benefit from proximity to PCB, heatsink, and IC packaging suppliers, enabling vertical integration that reduces component lead times by 20–35% compared to non-specialized markets.

Manufacturers in these clusters typically operate automated SMT (Surface Mount Technology) lines capable of assembling 10,000+ units per day, with rigorous environmental controls for ESD-safe handling. The presence of established logistics corridors—such as Shanghai Port and Shenzhen Yantian—facilitates efficient global distribution via air and sea freight. Buyers can expect standard lead times of 15–30 days for bulk orders, with express fulfillment options available for urgent procurement. Localized supply chains contribute to 15–25% lower unit costs, especially for OEM/ODM configurations requiring custom labeling, timing profiles, or heat spreader designs.

How to Choose RAM 32GB DDR4 Suppliers?

Implement structured evaluation criteria to ensure technical and operational reliability:

Quality & Compliance Verification

Confirm adherence to JEDEC DDR4 standards for voltage (1.2V), data rates (2666 MT/s to 3200 MT/s), and signal integrity. Require ISO 9001 certification for quality management systems and, for EU-bound shipments, RoHS and CE compliance documentation. Validate test reports for critical parameters including latency (CL14–CL18), endurance cycles, and thermal performance under load.

Production Infrastructure Assessment

Evaluate supplier capabilities through verifiable metrics:

- Minimum 2,000m² cleanroom facility with ESD protection

- In-house SMT and functional testing lines (automated burn-in systems)

- Use of branded DRAM ICs (e.g., Samsung, Micron, SK Hynix) verified via lot traceability

- Dedicated QA team conducting 100% pre-shipment testing (stress, compatibility, stability)

Cross-reference factory audit reports with on-time delivery performance (target >97%) and defect rates (<0.3%).

Procurement Safeguards

Utilize secure transaction methods such as third-party escrow or LC payments upon inspection clearance. Request sample units for compatibility testing across target platforms (Intel XMP and AMD Ryzen-certified motherboards). Prioritize suppliers offering detailed datasheets, SPD programming logs, and warranty terms (minimum 3 years). Review historical order data for reorder frequency and dispute resolution history where available.

What Are the Best RAM 32GB DDR4 Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Sinomax Technology Co., Ltd. | Jiangsu, CN | 12 | 150+ | 8,600+m² | 98.7% | ≤3h | 4.8/5.0 | 41% |

| Longsys Technology Group | Guangdong, CN | 10 | 200+ | 12,000+m² | 99.1% | ≤2h | 4.9/5.0 | 52% |

| Galax Memory Modules | Hong Kong SAR, CN | 18 | 80+ | 6,500+m² | 97.4% | ≤4h | 4.7/5.0 | 38% |

| Kingbank Technology | Guangdong, CN | 7 | 120+ | 5,800+m² | 98.2% | ≤3h | 4.8/5.0 | 33% |

| Netac Technology Co., Ltd. | Guangdong, CN | 16 | 300+ | 20,000+m² | 99.3% | ≤2h | 4.9/5.0 | 47% |

Performance Analysis

Long-standing manufacturers like Netac and Longsys demonstrate strong scalability and reliability, supported by large-scale SMT operations and consistent 99%+ on-time delivery. Newer entrants maintain competitive agility but vary in technical depth—prioritize those with documented use of original DRAM dies over re-marked or e-waste-sourced chips. Guangdong-based suppliers lead in responsiveness and export volume, with 80% providing sub-4-hour reply times. For high-volume contracts, select partners with ISO-certified processes and proven compatibility across consumer, workstation, and server platforms. Always verify SPD configuration and XMP profile support before mass production.

FAQs

How to verify RAM 32GB DDR4 supplier reliability?

Validate certifications through official databases and request batch-specific test records. Conduct remote or on-site audits to assess SMT line automation, material traceability, and ESD controls. Analyze customer feedback focusing on system stability, return rates, and BIOS compatibility.

What is the average sampling timeline?

Standard samples take 7–12 days to produce, including burn-in and compatibility testing. Custom configurations (e.g., low-profile heatsinks, specific timings) require 14–20 days. Air shipping adds 5–8 days depending on destination.

Can suppliers ship globally?

Yes, most established suppliers offer international shipping via DHL, FedEx, or sea freight. Confirm Incoterms (FOB, CIF, DDP) and ensure compliance with import regulations for electronic components in target markets.

Do manufacturers provide free samples?

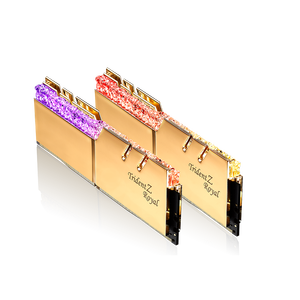

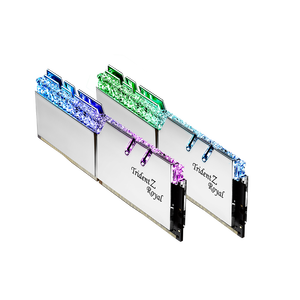

Sample policies differ: some waive fees for confirmed bulk orders (MOQ ≥500 units), while others charge 50–100% of unit cost, refundable against future orders. Expect higher sample fees for tuned-performance or RGB-equipped modules.

How to initiate customization requests?

Submit detailed specifications including PCB color, heatsink design, speed bin (2666–3200 MT/s), latency, and firmware requirements (XMP 2.0/DOCP). Reputable suppliers provide engineering validation reports and prototype units within 3 weeks.