Ramp For Loading Dock

Top sponsor listing

Top sponsor listing

1/3

1/3

0

0

1/3

1/3

0

0

1/3

1/3

0

0

0

0

1/23

1/23

1/2

1/2

1/17

1/17

1/3

1/3

0

0

1/3

1/3

1/18

1/18

1/2

1/2

1/1

1/1

1/3

1/3

1/3

1/3

0

0

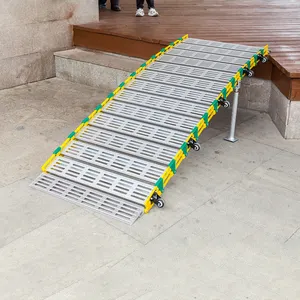

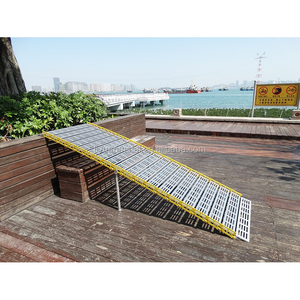

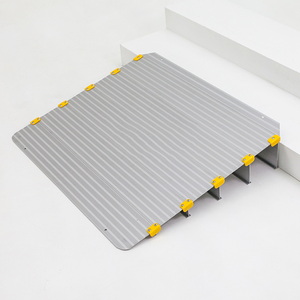

About ramp for loading dock

Where to Find Ramp for Loading Dock Suppliers?

China remains the global epicenter for industrial loading dock ramp manufacturing, with key production clusters in Fujian, Guangdong, Shandong, and Anhui provinces. These regions host vertically integrated metal fabrication ecosystems, enabling streamlined production from raw steel processing to final assembly. Xiamen and Foshan serve as primary hubs for export-oriented suppliers, leveraging coastal logistics infrastructure to reduce shipping lead times by 10–15 days compared to inland manufacturers.

Suppliers in these clusters benefit from proximity to Tier-1 steel mills and CNC component providers, allowing cost reductions of 18–25% on structural materials. The average facility operates across 3,000–8,000m² of production space, equipped with automated welding lines and powder-coating finishing systems. This integration supports rapid fulfillment cycles—standard orders typically ship within 20–35 days—with scalability for bulk procurement (MOQs from 1 to 10 sets depending on model complexity). Buyers also gain access to modular designs compatible with ISO container handling, forklift operations, and warehouse docking systems.

How to Choose Ramp for Loading Dock Suppliers?

Procurement decisions should be guided by three core verification criteria:

Technical Compliance

Confirm adherence to structural safety standards such as CE, ISO 9001, and load-bearing certifications (e.g., 10-ton capacity validation). Verify non-slip surface treatments, weld integrity reports, and material thickness specifications (typically 4–8mm carbon steel). For hydraulic models, demand documentation on cylinder pressure testing and control system reliability.

Production Capability Assessment

Evaluate supplier infrastructure through the following benchmarks:

- Minimum factory footprint of 3,000m² for consistent output

- In-house capabilities including laser cutting, robotic welding, and surface treatment

- Dedicated R&D or engineering support for custom modifications

Cross-reference on-time delivery rates (target ≥95%) and response times (≤3 hours) as indicators of operational efficiency and communication reliability.

Transaction and Quality Safeguards

Prioritize suppliers offering third-party inspection options prior to shipment. Utilize transaction platforms with verified payment escrow services to mitigate financial risk. Conduct sample testing for critical performance metrics: dynamic load capacity, ramp deflection under stress, and corrosion resistance of coated surfaces. Request test videos or facility walkthroughs to validate production processes before scaling orders.

What Are the Best Ramp for Loading Dock Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Key Product Examples |

|---|---|---|---|---|---|---|---|

| Xiamen Liyuan Metal Co., Ltd. | Fujian, CN | Bathroom Safety Equipment (652), Motorcycle Ramps & Stands (529) | 98% | 20% | ≤3h | US $1,600,000+ | Steel container ramps, manual dock plates |

| Foshan Xinsheng Mechanical Equipment Co., Ltd. | Guangdong, CN | Loading Ramps, Plates & Boards (49), Other Lift Tables (136) | 95% | 100% | ≤2h | US $600,000+ | Hydraulic yard ramps, adjustable container ramps |

| Qingdao Betterbe Machinery Co., Ltd. | Shandong, CN | Cargo & Storage Equipment (44), Forklift Attachments (16) | 100% | <15% | ≤3h | US $2,000+ | Mobile steel ramps, dock levelers |

| Guangdong Haoxiang Machinery Manufacturing Co., Ltd. | Guangdong, CN | Loading Ramps, Plates & Boards (57), Other Lift Tables (83) | 100% | - | ≤3h | - | Adjustable hydraulic ramps, CE-certified mobile docks |

| Anhui Biaowei Machinery Manufacturing Co., Ltd. | Anhui, CN | Truck Body Parts (901), Hydraulic Cylinders (45) | 93% | 25% | ≤1h | US $170,000+ | Telescopic dock levelers, T-shaped loading ramps |

Performance Analysis

Foshan Xinsheng stands out with a 100% reorder rate and sub-2-hour response time, indicating strong customer satisfaction and operational responsiveness. Qingdao Betterbe and Guangdong Haoxiang achieve perfect on-time delivery records, suggesting robust production planning despite lower online revenue visibility. Xiamen Liyuan offers broad product diversity and high transaction volume, reflecting established export experience. Anhui Biaowei excels in rapid communication (≤1h response) and specializes in hydraulic-powered solutions, though its 93% delivery rate warrants closer logistical scrutiny. Buyers seeking standardized steel ramps may prioritize cost-effective options from Shandong-based suppliers, while those requiring hydraulic automation should evaluate Guangdong and Fujian manufacturers with documented CE compliance.

FAQs

How to verify ramp for loading dock supplier reliability?

Audit supplier credentials by validating ISO or CE certifications through official registries. Request quality control documentation covering material sourcing, weld inspections, and load testing. Analyze transaction history, focusing on consistent on-time delivery and post-sale support metrics.

What is the typical lead time for standard ramp orders?

Standard models require 20–35 days for production and pre-shipment preparation. Hydraulic or custom-engineered units may extend to 45 days. Air freight samples arrive in 7–12 days; sea freight transit ranges from 18–30 days depending on destination port.

Do suppliers support customization?

Yes, most suppliers offer adjustments in length (2–12m), width (1.5–2.5m), load capacity (5–20 tons), and deployment method (manual, hydraulic, or mobile). Provide technical drawings or use case specifications to receive accurate quotations and prototype timelines.

What are common MOQs for loading dock ramps?

MOQs vary by design: single-unit orders are accepted for high-value hydraulic models, while basic steel ramps often require 10-piece minimums. Bulk pricing applies at 20+ units, with potential savings of 12–18%.

Are samples available before bulk ordering?

Sample availability depends on supplier policy. Some provide paid samples (priced at 1.5–2x unit cost) with credit toward future orders. For customized ramps, expect prototype development within 15–25 days after design approval.