Rapid Pcb Prototyping

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About rapid pcb prototyping

Where to Find Rapid PCB Prototyping Suppliers?

China remains the global hub for rapid PCB prototyping services, with Shenzhen and Qingdao emerging as key manufacturing clusters due to their specialized electronics ecosystems. Shenzhen, a recognized center for printed circuit board innovation, hosts vertically integrated facilities offering end-to-end solutions—from design validation to assembly—supported by localized component sourcing and advanced fabrication lines. This concentration enables lead times as short as 24–72 hours for double-sided prototypes and 5–7 days for complex multilayer or rigid-flex boards.

The region’s mature supply chain infrastructure reduces material procurement cycles by up to 40% compared to non-specialized regions. Suppliers in Shenzhen leverage proximity to semiconductor distributors, surface mount technology (SMT) providers, and testing labs, enabling seamless transitions from Gerber file submission to functional units. In contrast, Qingdao-based suppliers focus on hybrid prototyping models, combining CNC machining and 3D printing with electronic integration, catering to cross-disciplinary product development needs. Buyers benefit from competitive pricing structures, with per-unit prototype costs starting below $0.20 for simple designs at minimal order quantities (MOQ: 1–10 pieces).

How to Choose Rapid PCB Prototyping Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capabilities

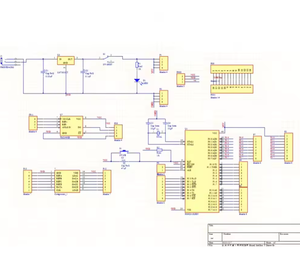

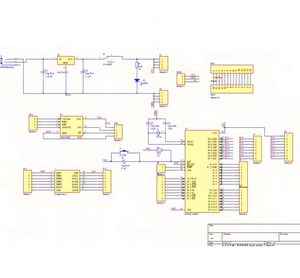

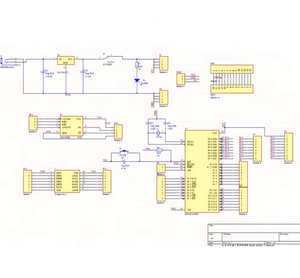

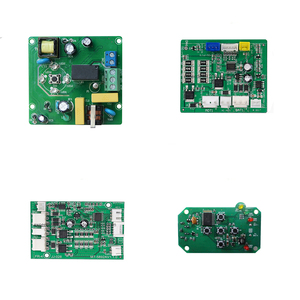

Confirm support for essential PCB types: single/double-sided, multilayer (up to 16 layers), FPC (flexible printed circuits), and rigid-flex configurations. Verify compatibility with standard formats (Gerber, Excellon, IPC-2581) and processing techniques including laser drilling, impedance control, and ENIG/OSP surface finishes. For PCBA (printed circuit board assembly), assess pick-and-place accuracy, reflow profiling, and AOI (automated optical inspection) availability.

Quality Assurance & Compliance

Prioritize suppliers adhering to IPC-A-600H (acceptability of printed boards) and IPC-A-610 (acceptability of electronic assemblies) standards. While formal ISO 9001 certification is not universally declared in available data, consistent on-time delivery rates above 94% correlate with robust internal quality management systems. RoHS compliance should be confirmed for prototypes intended for EU or North American markets.

Operational Performance Metrics

Evaluate based on measurable KPIs:

- On-time delivery rate ≥94%

- Average response time ≤3 hours

- Reorder rate >20% indicating customer retention

- Customization depth: silk screen, solder mask color, layer count, material type (FR-4, aluminum, polyimide)

Cross-reference these metrics with production scalability indicators such as online annual revenue (e.g., US $40,000+ for established suppliers) and facility specialization.

What Are the Best Rapid PCB Prototyping Suppliers?

| Company Name | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options | Verified Status |

|---|---|---|---|---|---|---|---|

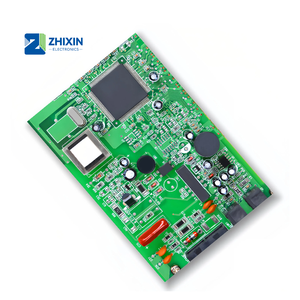

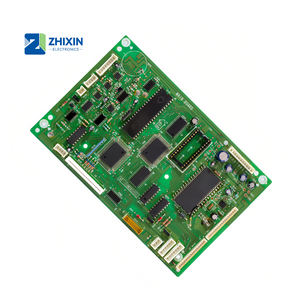

| Zhixinda Electronics (Shenzhen) Co., Ltd. | PCBA, Multilayer PCB, FPC, Rigid-Flex PCB | 100% | ≤3h | 72% | US $50,000+ | Color, material, size, logo, packaging, label, graphic | Multispecialty Supplier |

| Shenzhen Chengjieda Industry Limited | PCBA, Other PCB & PCBA | 94% | ≤2h | 30% | US $40,000+ | Color, material, size, logo, packaging, label, graphic | Multispecialty Supplier |

| Shenzhen Merrillchip Electronics Co., Ltd. | MCPCBA, Rapid Prototype Services | 85% | ≤8h | 19% | US $20,000+ | Silk print, spray paint, thickness, patch coordinates, Gerber files, layers, design drawings | Multispecialty Supplier |

| Hsr Prototype Limited | Machining Services, Moulds, Sheet Metal Fabrication | 100% | ≤3h | 22% | US $10,000+ | Limited PCB-specific customization | Not specified |

| 24K Investment (Qingdao) Co., Ltd. | Machining, Casting, Sheet Metal, Moulds | 94% | ≤2h | 20% | US $10,000+ | Primarily mechanical prototyping focus | Not specified |

Performance Analysis

Zhixinda Electronics stands out with a 100% on-time delivery record, 72% reorder rate, and comprehensive customization capabilities, positioning it as a top-tier provider for high-integrity PCB prototyping. Its multispecialty verification and broad product range suggest scalability for both low-volume trials and mid-scale production. Shenzhen Chengjieda matches strong operational reliability (94% on-time delivery, ≤2h response) with deep technical customization, ideal for iterative design validation.

While Hsr Prototype and 24K Investment report perfect or near-perfect delivery performance, their core expertise lies in mechanical rather than electronic prototyping, which may limit suitability for full PCBA projects. Shenzhen Merrillchip offers detailed design flexibility but lags in reorder rate and response speed, suggesting potential service bottlenecks. Buyers requiring fast-turn, high-complexity prototypes should prioritize Shenzhen-based suppliers with proven electronics-specific workflows and documented process controls.

FAQs

What is the typical lead time for rapid PCB prototypes?

Standard turnaround ranges from 24–72 hours for double-sided boards and 5–7 days for multilayer (4–16 layers) or rigid-flex designs. Expedited services may reduce this by 24–48 hours with premium fees.

Do suppliers accept orders of one piece?

Yes, most suppliers listed offer MOQs of 1 piece for prototype runs, particularly for bare PCBs. Assembled units (PCBA) may require minimum batches of 10–100 depending on complexity.

Can I customize solder mask color, silkscreen, and base material?

Extensive customization is available across leading suppliers, including green/red/blue/black solder masks, white silkscreen, FR-4/high-Tg/alu-core substrates, and impedance-controlled layouts.

How are quality issues resolved during prototyping?

Suppliers typically provide post-fabrication inspection reports and support revision iterations. Some offer free remake policies for verified manufacturing defects, contingent on design rule compliance.

What file formats are required for submission?

Standard requirements include Gerber (RS-274X), drill files (Excellon), BOM (for PCBA), and centroid data. Advanced suppliers also accept ODB++ and IPC-2581 formats for enhanced data integrity.