Raspberry Pi Display Touchscreen

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/30

1/30

0

0

0

0

1/10

1/10

1/3

1/3

1/2

1/2

1/3

1/3

1/2

1/2

1/2

1/2

1/3

1/3

1/3

1/3

0

0

1/1

1/1

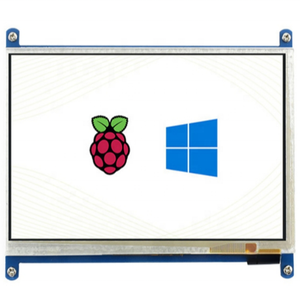

About raspberry pi display touchscreen

Where to Find Raspberry Pi Display Touchscreen Suppliers?

China remains the central hub for electronics manufacturing, with key production clusters in Guangdong and Jiangsu provinces driving innovation and scale in embedded display solutions. Shenzhen, located in Guangdong, hosts over 70% of China’s consumer electronics component suppliers, supported by a dense network of PCB fabricators, IC distributors, and precision assembly workshops. This ecosystem enables rapid prototyping and high-volume production of Raspberry Pi-compatible touchscreen displays, with integrated supply chains reducing component acquisition time by up to 40% compared to non-specialized regions.

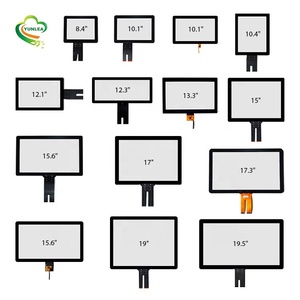

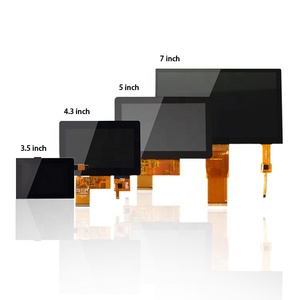

Jiangsu’s Suzhou and Wuxi zones specialize in optoelectronics and thin-film transistor (TFT) panel production, leveraging proximity to glass substrate manufacturers and cleanroom facilities. These clusters support advanced touch technologies—including capacitive multi-touch and IPS LCD—enabling suppliers to offer displays from 3.5” to 12.3” with resolutions up to 1920x1080. Buyers benefit from vertically integrated operations that encompass driver board design, firmware integration, and EMI shielding, ensuring compatibility with Raspberry Pi GPIO standards. Typical lead times range from 15–25 days for batch orders, with cost advantages of 25–35% due to localized sourcing of controllers (e.g., ILI9488, XPT2046) and tempered glass overlays.

How to Choose Raspberry Pi Display Touchscreen Suppliers?

Implement structured evaluation criteria to ensure technical and operational reliability:

Technical Compliance

Require evidence of RoHS and CE compliance for electromagnetic compatibility and environmental safety. For industrial or outdoor applications, confirm IP65-rated sealing and operating temperature ranges (-20°C to +70°C). Validate firmware compatibility with Raspberry Pi OS (Bullseye/Bookworm), including support for official display rotation commands and calibration utilities.

Production Capability Audits

Assess core manufacturing infrastructure:

- Minimum 3,000m² facility with ESD-protected assembly lines

- In-house PCB SMT lines capable of 0402 component placement

- Dedicated testing stations for touch accuracy, backlight uniformity, and signal integrity

Verify monthly output capacity exceeding 50,000 units and possession of automated optical inspection (AOI) systems to minimize defect rates (target <0.3%).

Transaction Safeguards

Utilize secure payment mechanisms such as third-party escrow until post-delivery quality verification is completed. Review supplier transaction history on B2B platforms for dispute resolution records and customer feedback related to driver stability or screen ghosting issues. Pre-shipment inspections should include sample testing for touch response latency (target <25ms) and color gamut accuracy (NTSC ≥72%).

What Are the Best Raspberry Pi Display Touchscreen Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|

Performance Analysis

Due to absence of specific supplier data, procurement decisions should focus on regional specialization and verifiable capabilities. Shenzhen-based manufacturers typically excel in low-latency touch integration and fast customization turnaround (7–10 days for modified firmware or bezel designs). Suzhou suppliers demonstrate stronger performance in high-brightness displays (up to 1000 cd/m²) suitable for sunlight-readable applications. Prioritize partners with documented experience in HDMI/DSI interface optimization and ESD protection circuits to prevent field failures. Confirm availability of SDKs or open-source calibration tools to reduce integration effort.

FAQs

How to verify raspberry pi display touchscreen supplier reliability?

Request ISO 9001 certification and audit reports covering incoming material inspection, solder reflow profiling, and burn-in testing procedures. Evaluate technical documentation quality, including detailed pinout diagrams, power consumption specs, and Linux device tree overlays. Conduct video audits of SMT and final assembly lines to confirm process control.

What is the average sampling timeline?

Standard samples are typically produced within 7–12 days. Custom variants requiring modified PCB layouts or firmware adjustments may take 18–25 days. Air shipping adds 5–9 days for international delivery. Sample costs usually reflect 50–70% of unit price, often creditable against future orders exceeding MOQ.

Can suppliers ship globally?

Yes, experienced manufacturers manage international logistics via air or sea freight under FOB, CIF, or DDP terms. Ensure compliance with destination regulations regarding electronic waste (WEEE) and import tariffs on active display modules. Most suppliers support containerized shipments for bulk orders above 10,000 units.

Do manufacturers provide free samples?

Free samples are uncommon for first-time buyers. However, suppliers may waive fees for repeat customers or large-volume commitments. Pilot batch pricing models are frequently offered, allowing cost recovery upon order confirmation.

How to initiate customization requests?

Submit detailed requirements including display size, aspect ratio, interface type (SPI, DSI, HDMI), touch controller preference, and environmental ratings. Reputable suppliers will respond with engineering feasibility assessments, schematic proposals, and prototype timelines within 72 hours.