Relativity Space 3d Printed Rocket

About relativity space 3d printed rocket

Where to Find 3D Printed Rocket Component Suppliers?

China leads in advanced additive manufacturing for aerospace applications, with key supplier clusters concentrated in Shandong and Guangdong provinces. Yantai in Shandong has emerged as a hub for inflatable aerospace models used in promotional and exhibition contexts, leveraging localized textile and PVC fabrication networks. Meanwhile, Qingdao and Guangzhou specialize in precision 3D printing services using industrial-grade polymers and metals, supported by integrated prototyping ecosystems that enable rapid iteration for complex geometries typical in rocket design.

These regions offer scalable production infrastructures combining automated 3D printing farms with post-processing capabilities such as sanding, painting, and assembly. Suppliers benefit from proximity to material suppliers and logistics centers, reducing lead times by up to 25% compared to decentralized setups. Buyers gain access to flexible manufacturing cells capable of producing both full-scale display models and functional prototypes, with average monthly output ranging from 100–500 units depending on complexity. The integration of SLA, SLS, FDM, and PolyJet technologies allows for material-specific solutions across ABS, resin, nylon, and titanium-based prints.

How to Choose 3D Printed Rocket Model Suppliers?

Selecting reliable suppliers requires adherence to structured evaluation criteria:

Technical Capability Verification

Confirm the availability of multi-technology 3D printing platforms (SLA/SLS/FDM) for material versatility. For engineering-grade components, validate use of high-strength thermoplastics (e.g., ABS, ULTEM) or metal printing (titanium, aluminum). Suppliers should provide build volume specifications—critical for large rocket segments—and support file formats including STL, STEP, and IGES.

Production Infrastructure Assessment

Evaluate operational scale through key indicators:

- Minimum 1,000m² facility area for end-to-end processing

- In-house post-processing stations (curing, dyeing, coating)

- Digital workflow integration from CAD to print execution

Cross-reference online revenue data and on-time delivery rates (>94% recommended) to assess operational stability and order prioritization.

Quality & Transaction Assurance

Prioritize suppliers with documented quality management practices, including first-article inspection reports and batch traceability. While formal ISO certification is limited among smaller prototyping firms, a reorder rate exceeding 20% indicates customer satisfaction. Use secure transaction mechanisms and request physical samples before scaling orders, especially for color-critical or dimensionally precise components.

What Are the Best 3D Printed Rocket Model Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

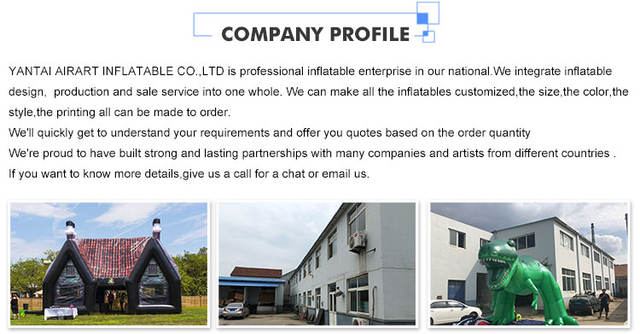

| Yantai Artair Inflatable Co., Ltd. | Shandong, CN | Advertising Inflatables, Party Decorations | 94% | <15% | ≤7h | $350,000+ | 1 piece | $595–1,500 |

| Yantai Ada Inflatable Co., Ltd. | Shandong, CN | Advertising Inflatables | 66% | 25% | ≤6h | $20,000+ | 1 piece | $100–998 |

| 24K Investment (Qingdao) Co., Ltd. | Qingdao, CN | Machining & Fabrication Services | 94% | 20% | ≤2h | $10,000+ | 1–100 cm | $0.10–1.00 |

| Guangzhou Gaojie Model Design & Manufacturing Co., Ltd. | Guangdong, CN | Machining Services, Moulds | 100% | 85% | ≤5h | $30,000+ | 1 unit | $0.15–1.21 |

| TONGSHENG TONGCHUANG INTELLIGENT EQUIPMENT COMPANY LIMITED | Guangdong, CN | Machining Services, Sheet Metal | 100% | - | ≤10h | $90+ | 100 pieces | $2.14–2.50 |

Performance Analysis

Guangzhou Gaojie stands out with a 100% on-time delivery rate and an exceptionally high 85% reorder rate, indicating strong customer retention and consistent output quality. The company’s per-unit pricing model starting at $0.15 makes it ideal for low-volume, high-precision prototype development. Yantai Artair offers premium inflatable rocket models suitable for outdoor advertising, though its lower reorder rate suggests limited repeat engagement outside event-based procurement cycles. 24K Investment (Qingdao) provides cost-effective custom 3D printing with centimeter-based billing, advantageous for partial or segmented builds. TONGSHENG TONGCHUANG supports bulk production with fixed pricing but requires higher MOQs, making it better suited for serial component runs than concept modeling.

FAQs

How to verify 3D printed rocket model accuracy?

Request dimensional inspection reports and coordinate measuring machine (CMM) data for critical features. Validate surface finish quality and layer adhesion through physical sample testing, particularly for load-bearing or aerodynamic components.

What is the typical lead time for custom 3D printed rockets?

Standard prototypes take 5–10 days for printing and finishing. Large or multi-part models (e.g., 8-meter inflatables) require 15–25 days due to extended curing and assembly phases. Add 7–14 days for international shipping via air freight.

Can suppliers produce flight-capable 3D printed parts?

While most listed suppliers focus on display or promotional models, select manufacturers like 24K Investment and TONGSHENG TONGCHUANG offer engineering-grade materials (ABS, titanium) compatible with non-flight structural applications. True flight-rated components require AS9100-certified facilities and are typically not available through general sourcing channels.

Do suppliers support design customization?

Yes, all listed vendors accept custom designs. Provide detailed 3D CAD files for accurate quoting. High-reputation suppliers offer design-for-additive-manufacturing (DfAM) feedback to optimize part geometry, reduce weight, and improve print success rates.

Are there minimum order requirements for 3D printed parts?

MOQs vary: single-unit orders are accepted by most prototyping specialists, while bulk-focused suppliers require 100+ units. Unit pricing decreases significantly at scale, especially for resin and plastic prints where setup costs are amortized across batches.