Report File

Top sponsor listing

Top sponsor listing

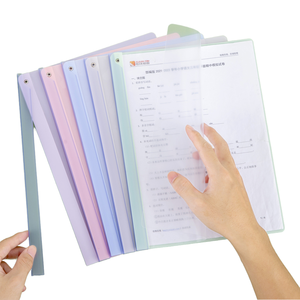

About report file

Where to Find Report File Suppliers?

China remains the global epicenter for report file manufacturing, with key production clusters in Guangdong and Zhejiang provinces driving supply chain efficiency. Guangdong—home to cities like Guangzhou and Dongguan—hosts vertically integrated plastic processing facilities specializing in PP and PVC-based stationery products. These hubs benefit from proximity to polymer raw material suppliers and export ports, reducing logistics costs by 10–15% compared to inland regions. Zhejiang’s Pujiang county has emerged as a niche center for eco-friendly filing solutions, leveraging local expertise in recyclable materials and automated die-cutting processes.

The concentration of suppliers in these regions enables economies of scale, with many factories operating end-to-end production lines from sheet extrusion to final packaging. Buyers gain access to rapid prototyping, consistent quality control, and flexible order sizing. Average lead times range from 15–25 days for standard orders, while localized component sourcing ensures 20–30% lower unit costs than equivalent Western or Southeast Asian producers. The ecosystem supports both high-volume procurement and customized product development across education, healthcare, and corporate sectors.

How to Choose Report File Suppliers?

Effective supplier selection requires systematic evaluation across three critical dimensions:

Production and Material Capabilities

Assess the supplier’s core materials (PP, PVC, recycled plastics) and processing techniques (thermal sealing, UV lamination, custom molding). Prioritize manufacturers with in-house tooling capacity for custom tabs, pockets, fasteners, or logo embossing. Confirm availability of A4, Letter, and legal sizes, along with color options beyond standard clear/translucent variants. Suppliers offering thickness customization (e.g., 0.3mm–0.8mm) demonstrate greater process control.

Quality and Operational Performance

Evaluate based on verifiable metrics:

- On-time delivery rate ≥97%

- Average response time ≤5 hours

- Reorder rate >20% indicating customer retention

- Minimum monthly output capacity of 100,000 units for volume stability

Cross-reference performance tags with product listing diversity—suppliers listing 100+ filing-related SKUs typically have dedicated production lines and inventory management systems.

Customization and Transaction Security

Verify support for branding elements such as printed labels, custom graphics, molded logos, and multi-language inserts. Ensure digital proofing is available before production. For transaction safety, confirm structured order tracking, sample validation protocols, and packaging compliance for international shipping. While formal certifications (ISO 9001, RoHS) are not universally listed, prioritize suppliers with documented quality checks and third-party audit readiness.

What Are the Best Report File Suppliers?

| Company Name | Main Materials | MOQ Range | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Filing Product Listings |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Daidong Future Stationery Products Co., Ltd. | PP, PVC | 3000–5000 units | $0.20–$1.30 | 100% | ≤1h | 22% | Color, size, logo, packaging, graphic | 405 |

| Pujiang Pangxin Stationery Co., Ltd. | PVC | 2000–5000 units | $0.17–$1.30 | 100% | ≤5h | 100% | Limited (product-specific) | 129 |

| Shantou Baina Stationery Industry Co., Ltd. | PP, Plastic | 100–2400 units | $0.10–$0.68 | 76% | ≤5h | 28% | Size, clips, design | 136 |

| Dongguan Unus Plastic Technology Co., Ltd. | PP | 100–1000 units | $0.19–$1.90 | 100% | ≤2h | <15% | Full: material, color, thickness, print, design | Not specified |

| Guangzhou Kama Bag Co., Ltd. | PVC | 100 units | $0.07–0.38 | 100% | ≤4h | <15% | Logo, color, size, print | 36 |

Performance Analysis

Guangzhou Daidong leads in product breadth and responsiveness, with a 100% on-time delivery rate and sub-1-hour average response, supported by extensive inventory (405 filing product listings). Pujiang Pangxin stands out for customer retention (100% reorder rate), indicating strong satisfaction despite fewer customization features. Shantou Baina offers competitive pricing starting at $0.10/unit but shows lower reliability (76% on-time delivery), warranting closer shipment monitoring. Dongguan Unus provides the most comprehensive customization suite, including mold and fastener design, ideal for specialized corporate or medical reports. Guangzhou Kama delivers ultra-low MOQs and entry-level pricing, suitable for small businesses or sampling, though its primary focus on bags suggests secondary positioning in filing products.

FAQs

What materials are commonly used in report files?

PP (polypropylene) and PVC (polyvinyl chloride) dominate the market. PP is preferred for durability, chemical resistance, and recyclability. PVC offers higher clarity and rigidity but is less environmentally friendly. Some suppliers offer biodegradable or recycled content variants upon request.

What is the typical minimum order quantity (MOQ)?

MOQs vary from 100 units for small suppliers to 2,000–5,000 units for bulk-focused manufacturers. Factories with automated lines often set higher thresholds, while those supporting sampling or e-commerce channels accept lower volumes at slightly elevated per-unit prices.

How long does production and shipping take?

Production lead time averages 15–20 days after sample approval. Air freight adds 5–7 days for urgent orders; sea freight requires 25–35 days depending on destination. Expedited processing (7–10 days) is available from select suppliers at a premium.

Can I request custom branding or design?

Yes, most established suppliers support full customization: logo printing, colored covers, branded tabs, pocket configurations, and insert pages. Digital proofs are typically provided within 48 hours. Mold development for unique shapes may require additional time (7–14 days) and NRE fees.

How do I verify product quality before ordering?

Request physical or digital samples to assess material thickness, seam strength, hinge durability, and print accuracy. Conduct functional tests for clip retention, pocket adhesion, and page capacity. For large contracts, consider third-party inspection services (e.g., SGS, BV) pre-shipment to validate consistency against specifications.