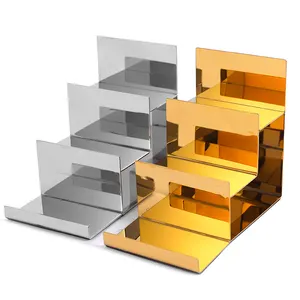

Retail Product Examples

VN

VN

About retail product examples

Where to Find Retail Product Display Suppliers?

China remains the central hub for retail product display manufacturing, with key production clusters in Guangdong, Fujian, and Zhejiang provinces. Shenzhen and Guangzhou in Guangdong province dominate cardboard and acrylic display fabrication, leveraging advanced digital printing and die-cutting infrastructure. Xiamen-based suppliers specialize in modular retail furniture and garment racks, integrating metalworking and woodworking capabilities within compact supply chains. These regions benefit from vertically integrated ecosystems where raw material sourcing, structural design, and logistics coordination occur within localized networks, reducing lead times by 25–40% compared to offshore alternatives.

The industrial clusters support high-volume output and rapid prototyping, with average monthly production capacities exceeding 50,000 units per facility. Suppliers commonly utilize recyclable corrugated board, powder-coated steel, and injection-molded plastics, enabling compliance with EU and North American sustainability standards. Buyers gain access to agile manufacturing bases capable of fulfilling both mass orders and low-MOQ custom projects, supported by responsive communication channels and digital workflow integration.

How to Choose Retail Product Display Suppliers?

Effective supplier selection requires systematic evaluation across three core dimensions:

Design and Customization Capability

Confirm suppliers offer end-to-end customization—from 3D renderings to finished assemblies—covering material grade, dimensional tolerance, graphic printing, and modular configuration. Leading vendors provide UV-resistant inkjet printing, rounded edge finishing, and disassembly-friendly designs for flat-pack shipping. Verify digital proofing turnaround (typically 24–48 hours) and request physical samples before scaling production.

Production Infrastructure Verification

Assess operational scale through measurable indicators:

- Minimum factory area of 2,000m² for consistent output stability

- In-house capabilities including CNC cutting, screen printing, and structural assembly lines

- Dedicated quality control teams conducting pre-shipment inspections

Cross-reference on-time delivery rates (target ≥95%) and reorder frequency to gauge reliability and customer satisfaction.

Transaction and Quality Assurance

Prioritize suppliers with documented quality management systems and responsive service protocols. Evaluate response time benchmarks (≤1 hour preferred), packaging standardization, and labeling accuracy. Where applicable, confirm RoHS or FSC compliance for material traceability. Utilize incremental ordering strategies—starting with sample batches—to validate performance before committing to large-scale procurement.

What Are the Top Retail Product Display Suppliers?

| Company Name | Location | Main Materials | Customization Options | MOQ Range | On-Time Delivery | Avg. Response | Reorder Rate | Annual Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Liushi Paper Packaging Co., Ltd. | Shenzhen, CN | Cardboard, Recycled Paper | Color, size, logo, packaging, graphic | 1 piece | 89% | ≤1h | 23% | US $670,000+ |

| Xiamen iYubo Tech Co., Ltd. | Xiamen, CN | Metal, Wood, Composite | Layout, color, design, logo, packaging, style | 1–50 pieces | 100% | ≤1h | <15% | US $20,000+ |

| Guangzhou Craftsman Xin Hardware Products Co., Ltd. | Guangzhou, CN | Metal, Steel, Composite | Limited (primarily size and finish) | 2–20 pieces | 100% | ≤1h | 15% | US $40,000+ |

| Xiamen Link-Trip Commerce Co., Ltd. | Xiamen, CN | Metal, LED-integrated Structures | Color, material, design, logo, packaging | 1–20 sets | 100% | ≤4h | 24% | US $440,000+ |

| Yinjie Media Advertising Production (Guangzhou) Co., Ltd. | Guangzhou, CN | PVC, Cardboard, Acrylic | Color, shape, thickness, printing, edge finish, logo | 10–50 pieces | 100% | ≤1h | 21% | US $80,000+ |

Performance Analysis

Shenzhen Liushi leads in volume-capable cardboard displays with the highest online revenue and single-unit MOQ flexibility, though its 89% on-time delivery rate indicates moderate logistical risk. Xiamen iYubo and Guangzhou Craftsman Xin achieve perfect delivery records, with iYubo offering broad customization for boutique retail environments. Yinjie Media stands out in precision thermoformed and printed displays, supporting complex branding requirements with UV printing and edge polishing. Xiamen Link-Trip commands premium pricing for LED-integrated metal displays, reflecting specialized engineering capacity. Buyers seeking rapid iteration should prioritize suppliers with ≤1h response times and sub-7-day sampling cycles.

FAQs

How to verify retail display supplier reliability?

Cross-check declared certifications and request evidence of quality control procedures, including material test reports and pre-shipment inspection logs. Analyze transaction history metrics such as on-time delivery rate, reorder frequency, and response consistency. Validate customization accuracy through sample evaluation under real-store lighting conditions.

What is the typical sampling timeline?

Standard display samples are produced within 5–7 days. Complex configurations involving mixed materials or electronic components (e.g., LED lighting) require 10–14 days. Add 3–7 days for international express delivery.

Can suppliers accommodate small batch orders?

Yes, most suppliers listed support low MOQs starting at 1 piece for cardboard displays and 10–20 units for metal or acrylic units. Unit cost decreases significantly at volumes above 100 pieces due to setup amortization.

Do manufacturers provide free samples?

Free samples are uncommon for custom displays. Suppliers typically charge 1.5–2x unit cost for prototypes, with partial or full credit applied upon order confirmation. Stock item samples may be offered at reduced fees.

How to initiate a custom retail display project?

Submit detailed specifications including product dimensions, weight load requirements, brand color codes (Pantone/CMYK), logo files (vector format), and preferred assembly method. Reputable suppliers respond with 3D mockups within 24–48 hours and provide structural stress analysis for floor-standing units.