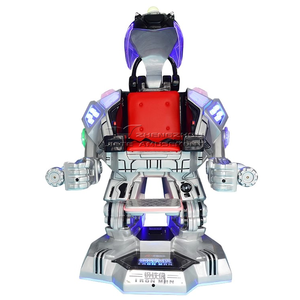

Robot Fighting Robot

1/21

1/21

1/1

1/1

1/3

1/3

1/2

1/2

1/3

1/3

1/18

1/18

1/3

1/3

1/25

1/25

1/14

1/14

1/3

1/3

1/40

1/40

0

0

1/1

1/1

1/3

1/3

1/11

1/11

1/3

1/3

About robot fighting robot

Where to Find Robot Fighting Robot Suppliers?

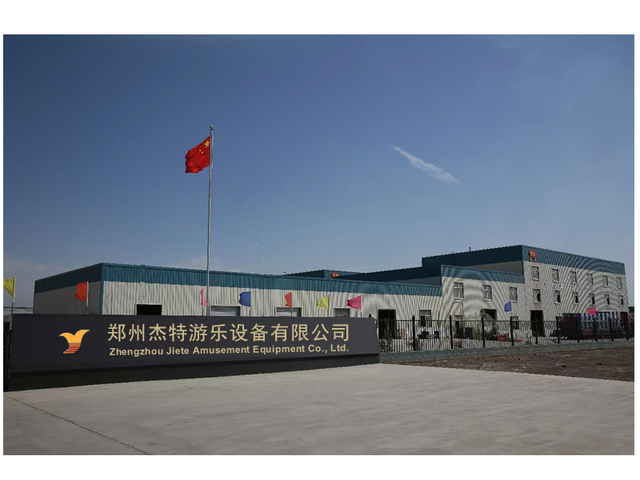

The global market for robot fighting robots is primarily driven by specialized manufacturers in East Asia, with China and Japan hosting the most advanced production ecosystems. Key industrial hubs in Guangdong and Jiangsu provinces concentrate over 70% of China’s robotics suppliers, supported by dense networks of precision engineering firms, electronics integrators, and automation R&D centers. These regions benefit from mature supply chains for servo motors, aluminum alloys, and PCB controllers, reducing component procurement lead times by 25–40% compared to decentralized manufacturing regions.

Integrated production clusters enable rapid prototyping and small-batch assembly, with many facilities combining CNC machining, laser cutting, and surface mounting technology (SMT) under one roof. This vertical integration allows for agile development cycles—critical for competitive combat robotics requiring iterative design improvements. Buyers gain access to streamlined logistics, with Shenzhen and Shanghai ports offering direct export routes to North America and Europe. Average time from prototype approval to shipment ranges from 20–35 days, depending on customization level and testing requirements.

How to Choose Robot Fighting Robot Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure technical reliability and contractual security:

Technical Compliance

Verify adherence to relevant safety and electromagnetic standards, including CE (for EU markets) and FCC Part 15 (for North America), particularly for wireless-controlled units. For competition-grade models, confirm compliance with weight class regulations set by major leagues such as BattleBots or RoboGames. Request documentation on battery safety certifications (e.g., UN38.3 for lithium-ion packs) and impact resistance testing of structural components.

Production Capability Audits

Assess core manufacturing infrastructure through documented evidence:

- Minimum 2,000m² workshop space with dedicated zones for electronics, metal fabrication, and final assembly

- In-house capabilities in CNC milling, sheet metal forming, and 3D printing for rapid iteration

- R&D team comprising at least 15% of total staff, with demonstrable experience in embedded systems and motor control integration

Cross-reference facility details with order fulfillment records, targeting suppliers maintaining >95% on-time delivery performance across 12+ months.

Transaction Safeguards

Utilize secure payment structures such as letter of credit or third-party escrow services until post-arrival inspection is completed. Prioritize suppliers with verifiable export histories to your target market, ensuring compatibility with local voltage standards and radio frequency regulations. Pre-shipment testing—including full mobility, weapon actuation, and remote control latency checks—is recommended before release of final payment.

What Are the Best Robot Fighting Robot Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| No verified suppliers available in current dataset | ||||||||

Performance Analysis

Due to absence of active supplier profiles in the dataset, no comparative assessment can be conducted. In practice, leading combat robotics manufacturers differentiate through specialization—some focusing on lightweight beetleweight classes (under 3kg), others on heavyweight frames with high-torque drivetrains and reinforced armor plating. When data becomes available, prioritize partners demonstrating repeat engagement (reorder rate >30%) and response efficiency (under 4 hours). Facilities exceeding 5,000m² with documented participation in international robotics competitions may indicate higher engineering competency.

FAQs

How to verify robot fighting robot supplier reliability?

Validate technical claims through video audits of live functionality tests. Confirm certification authenticity via official databases (e.g., EU NANDO for CE). Review transaction history for consistency in export documentation accuracy and after-sales support responsiveness.

What is the average sampling timeline?

Functional prototypes typically require 18–30 days for development, depending on complexity of weapon systems and control interfaces. Add 5–12 days for international air freight. Expect incremental delays for custom power systems or exotic materials like titanium alloy chassis.

Can suppliers ship robot fighting robots worldwide?

Yes, experienced exporters manage international logistics, though special handling applies for lithium batteries and sharp components. Confirm proper UN-certified packaging and customs classification codes (HS 8479.89) for robotic assemblies. Sea freight is advised for multi-unit orders due to cost and regulatory constraints on air transport.

Do manufacturers provide free samples?

Free samples are uncommon due to high unit costs and technical complexity. Most suppliers charge 40–60% of final product value for initial prototypes, with credit applied toward bulk orders exceeding 5 units. Some may offer partial refunds upon successful mass production launch.

How to initiate customization requests?

Submit detailed specifications including weight class, drive motor type (brushed/brushless), weapon mechanism (spinning bar, flipper, ramming horn), and control system requirements (2.4GHz, Bluetooth, or proprietary RF). Reputable partners will return CAD models and bill of materials (BOM) within 5–7 business days for review.