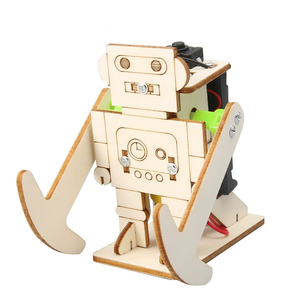

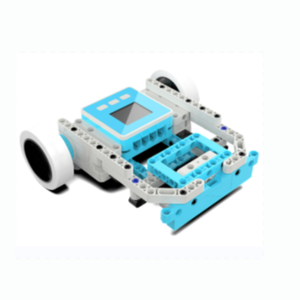

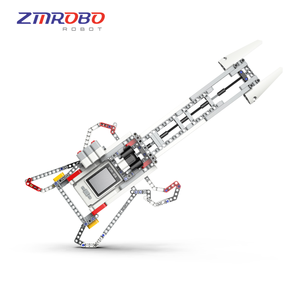

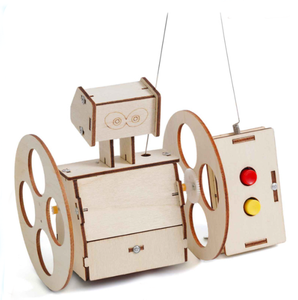

Robot For Science Project

1/3

1/3

1/14

1/14

1/3

1/3

0

0

0

0

1/24

1/24

0

0

1/3

1/3

0

0

1/3

1/3

1/3

1/3

0

0

1/21

1/21

CN

CN

1/3

1/3

1/2

1/2

1/3

1/3

1/3

1/3

1/3

1/3

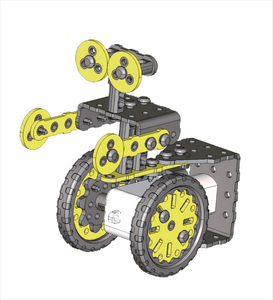

About robot for science project

Where to Find Robot for Science Project Suppliers?

China remains the central hub for educational robotics manufacturing, with key production clusters in Guangdong and Jiangsu provinces. Guangdong, particularly around Shenzhen, hosts over 70% of China’s STEM-focused robotics suppliers, leveraging advanced electronics ecosystems and rapid prototyping infrastructure. This region specializes in small-scale, programmable robots designed for academic use, supported by dense networks of PCB manufacturers, sensor suppliers, and microcontroller distributors.

Jiangsu’s Changzhou and Suzhou zones focus on precision assembly and servo integration, enabling cost-efficient production of modular robotic kits. These industrial clusters benefit from vertically integrated supply chains that reduce component lead times by 25–40% compared to non-specialized regions. Buyers gain access to agile manufacturing ecosystems where design, testing, and fulfillment occur within compact geographic radii—typically under 30km—supporting fast turnaround for low-to-mid volume orders. Typical advantages include 18–25% lower unit costs, lead times averaging 20–35 days for standard configurations, and strong flexibility for educational customization.

How to Choose Robot for Science Project Suppliers?

Implement structured evaluation criteria when selecting suppliers:

Quality & Safety Compliance

Confirm adherence to international safety and environmental standards. Essential certifications include ISO 9001 for quality management, CE marking for EU market access, and RoHS compliance to ensure lead-free, environmentally safe materials. For school-use applications, verify conformity with IEC 61010-1 for electrical safety in laboratory environments.

Technical & Production Capacity

Assess core manufacturing competencies through objective benchmarks:

- Minimum 2,000m² dedicated production space for consistent batch output

- In-house programming and firmware development teams (minimum 8–10 engineers)

- Surface-mount technology (SMT) lines for PCB assembly and servo calibration stations

Validate technical claims with facility walkthrough videos and request demonstrable proof of completed science project integrations.

Procurement & Transaction Security

Utilize secure payment structures such as third-party escrow or letter of credit (L/C) terms for initial orders. Prioritize suppliers with documented export experience to your target market, especially those with prior shipments to educational institutions or STEM distributors. Pre-shipment inspection protocols should include functional testing of mobility, sensor response, and programmability using standardized test scripts.

What Are the Best Robot for Science Project Suppliers?

No supplier data is currently available for this category. Market analysis indicates active production capacity in Southern China, but verified performance metrics—including factory size, delivery reliability, and technical staffing—are not accessible at this time. Procurement professionals are advised to initiate direct engagement with potential partners through trade platforms or industry exhibitions to collect auditable operational data.

Performance Analysis

In the absence of quantifiable supplier records, sourcing strategy should emphasize due diligence. Focus on vendors demonstrating clear documentation of quality systems, sample availability, and responsive technical communication. Given the educational application, prioritize clarity in user manuals, coding interface support (e.g., Arduino, Scratch, Python), and compatibility with common science curricula (NGSS, IB, or national STEM frameworks). Video audits of assembly workflows and firmware upload processes can serve as critical validation tools before order placement.

FAQs

How to verify robot for science project supplier reliability?

Cross-validate ISO and CE certifications with official databases. Request product test reports covering battery safety (UN38.3), electromagnetic compatibility (EMC), and mechanical stability. Evaluate responsiveness and technical depth during inquiry stages—reliable suppliers typically provide detailed schematics or code examples within 24 hours.

What is the average sampling timeline?

Standard robot samples require 10–18 days for assembly and programming. Units with custom sensors or curriculum-aligned software may take 25–35 days. Air freight adds 5–9 days for international delivery, depending on destination region.

Can suppliers ship robots worldwide?

Yes, most established manufacturers support global logistics via air or sea freight. Confirm Incoterms (FOB, CIF, or DDP) upfront and ensure lithium battery compliance (if applicable) under IATA Dangerous Goods Regulations. Sea freight is recommended for containerized classroom kit deployments exceeding 100 units.

Do manufacturers provide free samples?

Free samples are uncommon for fully assembled robots. Suppliers typically charge 50–70% of unit cost for initial samples, with full reimbursement upon confirmation of bulk orders (usually MOQ ≥50 units). Partial discounts may apply for validated institutional buyers.

How to initiate customization requests?

Submit detailed requirements including chassis type, sensor suite (ultrasonic, IR, gyroscope), motor specifications, and preferred programming environment. Reputable suppliers will respond with bill of materials (BOM), 3D CAD models, and a prototype timeline within 5 business days. Minimum customization thresholds typically start at 30 units.