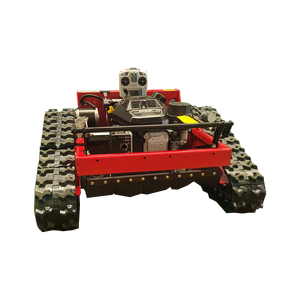

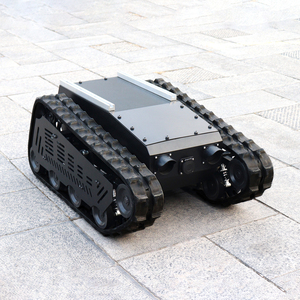

Robot Mini Producer

About robot mini producer

Where to Find Robot Mini Producer Suppliers?

China remains the central hub for compact industrial robotics manufacturing, with key production clusters in Shenzhen and Shanghai driving innovation and cost efficiency. These regions host vertically integrated facilities capable of full-cycle development—from design and prototyping to mass production—enabling rapid deployment of mini robotic systems tailored for precision automation tasks. Shenzhen-based suppliers benefit from proximity to semiconductor and electronics supply chains, optimizing production for lightweight, high-precision robotic arms used in assembly, palletizing, and material handling.

The ecosystem supports scalable output with modular production lines, allowing manufacturers to maintain low minimum order quantities (MOQs) while fulfilling custom configurations. Lead times for standard mini robot units typically range from 15 to 30 days, with express processing options available for urgent procurement. Localization of core components such as servo motors, controllers, and end-effectors reduces dependency on international sourcing, contributing to 20–30% lower production costs compared to equivalent systems manufactured outside Asia. Buyers gain access to agile suppliers equipped for both single-unit educational models and multi-unit industrial deployments.

How to Choose Robot Mini Producer Suppliers?

Evaluating suppliers requires a structured assessment across technical, operational, and transactional dimensions:

Technical & Production Capabilities

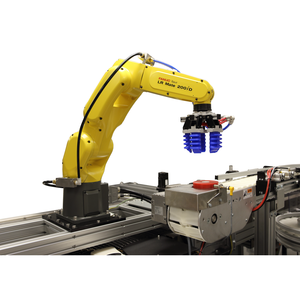

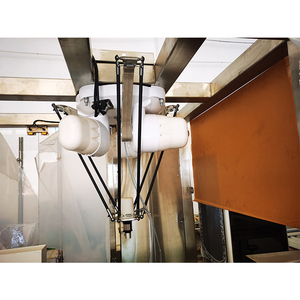

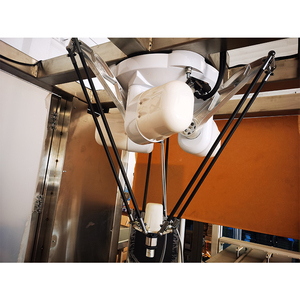

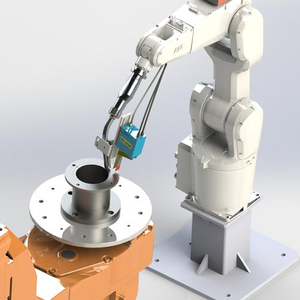

Confirm whether the supplier operates an in-house production line with CNC machining, robotic calibration, and testing infrastructure. Priority should be given to companies listing articulated robots, parallel robots, or manipulators as core product categories, indicating specialized expertise. For industrial-grade units, verify payload capacity (typically 0.5–3kg), degrees of freedom (4-axis to 6-axis), and repeatability specifications (±0.02mm to ±0.1mm). Educational or toy-grade robots may lack CE or ISO certification and are unsuitable for factory automation.

Quality Assurance & Compliance

Industrial mini robots must comply with relevant safety and electromagnetic compatibility standards. While formal certifications (e.g., ISO 9001, CE, RoHS) are not universally listed, buyers should request compliance documentation prior to purchase. High-performing suppliers demonstrate consistent on-time delivery rates (≥95%) and sub-6-hour response times, indicators of operational discipline and customer service maturity.

Procurement Risk Mitigation

Utilize secure payment methods with escrow protection, especially when dealing with newer suppliers lacking extensive transaction histories. Analyze reorder rates as a proxy for customer satisfaction—suppliers exceeding 100% reorder rate indicate strong post-sale support and product reliability. Request product videos or facility walkthroughs to validate claims about production autonomy and inventory availability. Pre-shipment inspections are recommended for orders exceeding five units.

What Are the Best Robot Mini Producer Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Product Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Zhongyi Industrial Co., Ltd. | Shenzhen, CN | Articulated Robots (824) | 100% | ≤1h | - | - | $1,897–14,310 | 1 set |

| Shanghai Jiesheng Robot Co., Ltd. | Shanghai, CN | Manipulator (145), Articulated Robots (86) | 100% | ≤6h | - | - | $15,000–20,000 | 1 unit |

| Robot Anno (Shenzhen) Co., Ltd. | Shenzhen, CN | Vending Machines (415), Manipulator (258) | 100% | ≤4h | 18% | US $630,000+ | $1,798–6,120 | 1 piece/set |

| Robotphoenix Intelligent Technology Co.,Ltd | Shenzhen, CN | Manipulator (570), AGV (210), Parallel Robots (151) | 100% | ≤2h | 100% | US $30,000+ | $3,999–20,000 | 1 set/piece |

| Shantou Chenghai Yifan Toys Firm | Shantou, CN | Toy Robots (299), RC Cars (703) | 88% | ≤6h | 16% | US $5,000+ | $1.79–9.50 | 36–720 pieces |

Performance Analysis

Shenzhen and Shanghai-based industrial robotics suppliers dominate in technical capability and delivery consistency, with 100% on-time performance across verified producers. Robotphoenix stands out with a 100% reorder rate, suggesting robust after-sales service and system reliability. Shanghai Jiesheng focuses on premium Yaskawa-compatible MotoMINI systems, targeting high-precision applications at significantly higher price points ($15k–20k). In contrast, Shenzhen Zhongyi and Robot Anno offer competitively priced 4-axis and 6-axis models suitable for small-scale automation, with entry-level pricing below $2,000. Shantou-based Yifan Toys represents a non-industrial segment, producing consumer-grade robot toys at ultra-low cost but with limited scalability and technical support for commercial use.

FAQs

How to verify a robot mini producer’s technical capability?

Request proof of in-house production, including CNC equipment, robotic calibration tools, and testing protocols. Ask for detailed specifications—payload, reach, repeatability, and control interface—and cross-check against product images or demonstration videos. Suppliers specializing in manipulators or industrial robots are more likely to support OEM/ODM projects than toy-focused manufacturers.

What is the typical MOQ for mini industrial robots?

Most industrial suppliers accept orders starting at 1 set or unit, facilitating pilot testing and integration. However, toy-grade robots often require bulk purchases (36–720 pieces) due to mass-market distribution models. Negotiate sample terms before scaling up.

Are mini robots export-ready?

Yes, established suppliers manage global logistics via air or sea freight under FOB or CIF terms. Confirm packaging standards, voltage compatibility (110V/220V), and controller language options (English interface) prior to shipment. Industrial models typically include CE-marked components; request documentation to ensure customs clearance.

Can suppliers customize mini robots?

Industrial-focused producers like Shenzhen Zhongyi and Robotphoenix support customization of arm length, payload, mounting configuration, and software integration. Provide CAD files or functional requirements early in discussions. Turnaround for prototypes ranges from 2–4 weeks depending on complexity.

What are the common applications for mini robots from these suppliers?

Applications include small-part assembly, pick-and-place operations, spray painting, palletizing, and educational training. Delta-style and parallel robots suit high-speed packaging lines, while 6-axis articulated arms serve flexible manufacturing cells. Ensure alignment between robot specifications and intended workload to avoid underperformance.