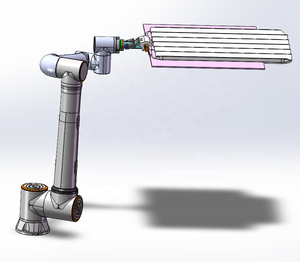

Robot Palletizer

Top sponsor listing

Top sponsor listing

1/14

1/14

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/25

1/25

1/3

1/3

1/1

1/1

1/1

1/1

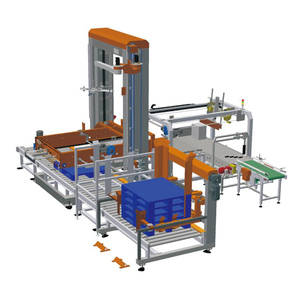

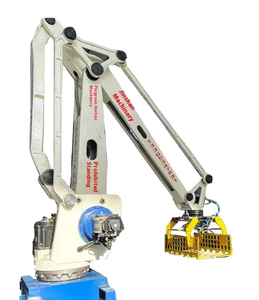

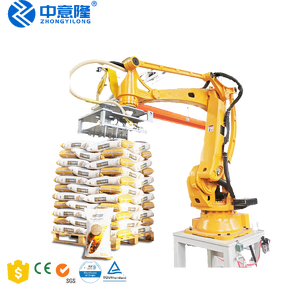

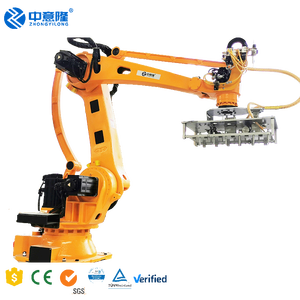

About robot palletizer

Where to Find Robot Palletizer Suppliers?

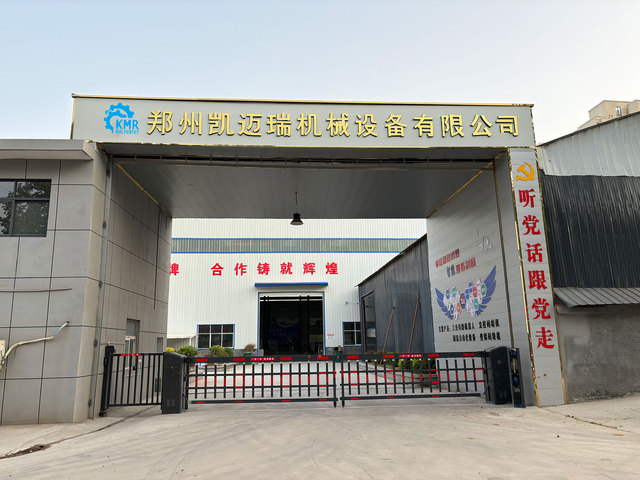

China remains the global epicenter for robot palletizer manufacturing, with key production clusters in Shandong, Anhui, Guangdong, and Tianjin. These regions host vertically integrated industrial ecosystems that combine robotic automation expertise with material handling engineering. Shandong’s Jining and Qingdao zones specialize in heavy-duty robotic systems, leveraging proximity to steel and conveyor component suppliers to reduce material costs by 15–20%. Hefei (Anhui) and Shenzhen (Guangdong) focus on compact cobot-based palletizers, integrating advanced control systems for food, pharmaceutical, and electronics packaging lines.

The concentration of technical talent and supply chain infrastructure enables rapid prototyping and scalable production. Facilities typically operate under ISO 9001 quality frameworks and maintain in-house design teams capable of generating CAD layouts, structural simulations, and integration schematics. Buyers benefit from lead times averaging 30–45 days for standard units, with customization cycles extending to 60 days depending on complexity. The ecosystem supports both high-volume procurement and engineered-to-order solutions, making it ideal for multinational operations seeking cost efficiency and technical flexibility.

How to Choose Robot Palletizer Suppliers?

Selecting a reliable supplier requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Integration Capability

Verify adherence to international safety and performance standards such as CE, ISO 10218 (industrial robots), and IEC 61508 (functional safety). Demand detailed documentation including electrical schematics, load capacity charts, cycle time analysis, and end-effector specifications. For seamless integration into existing lines, confirm supplier experience with common PLC platforms (Siemens, Allen-Bradley) and communication protocols (PROFINET, Modbus).

Production Capacity & Engineering Support

Assess core capabilities through verifiable metrics:

- Minimum factory area of 3,000m² for dedicated robotic assembly lines

- In-house engineering teams offering layout design, simulation modeling, and changeover programming

- Customization depth: ability to modify gripper type, reach radius, payload (5–1,000 kg), conveyor interface, and labeling/strapping integration

Cross-reference delivery performance (target ≥97% on-time rate) with response time (≤2 hours preferred) to gauge operational responsiveness.

Transaction Security & Quality Assurance

Prioritize suppliers offering third-party inspection options and milestone-based payment terms. Review historical reorder rates as an indicator of customer satisfaction—rates above 20% suggest consistent quality and service. Request sample testing under real-world conditions, particularly for dynamic parameters like stacking accuracy, uptime reliability, and fault recovery protocols.

What Are the Best Robot Palletizer Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Qingdao Ausense Packing Equipment Co., Ltd. | Shandong, CN | Custom Manufacturer | US $1.2M+ | 97% | ≤2h | 22% | Packaging Line, Wrapping Machines, Conveyors, Robotic Palletizers | Conveyor size, robotic arm specs, pallet weight, labeling, CAD layout, material, color, logo |

| Hefei Honor Automation Technology Co., Ltd. | Anhui, CN | - | US $20K+ | 100% | ≤2h | <15% | Industrial Robots, Automatic Palletizing Systems | Line design drawings, packing configuration |

| Shenzhen Fine Machine Co., Ltd. | Guangdong, CN | - | US $10K+ | 100% | ≤2h | <15% | Cobot Palletizers, Inkjet Printers, Multi-Function Packaging Lines | Payload (5–20kg), pick-and-place logic, integration with sealing/wrapping |

| Jining Shunyin Machinery Co., Ltd. | Shandong, CN | Multispecialty Supplier | US $680K+ | 98% | ≤1h | 20% | Column-Type Palletizers, Carton Manipulators, Stacking Systems | Carton size, color, material, logo, packaging label, graphic elements |

| Tianjin Peaks Co., Ltd. | Tianjin, CN | - | US $30K+ | 100% | ≤1h | <15% | Heavy-Duty 4-Axis Robots, High-Capacity Palletizers, Cement Bag Stackers | High-load configurations, articulated robot integration, multi-function automation |

Performance Analysis

Qingdao Ausense stands out for high-volume output and extensive customization breadth, supported by strong reorder activity (22%) and robust online revenue ($1.2M+). Jining Shunyin combines fast response times (≤1h) with proven delivery consistency (98%), making it suitable for urgent deployments. Hefei Honor, Shenzhen Fine, and Tianjin Peaks all achieve perfect on-time delivery records, though lower reorder rates suggest niche positioning or limited after-sales engagement. Tianjin Peaks targets high-capacity applications with prices exceeding $60,000 per unit, indicating specialization in industrial-scale automation. For mission-critical installations, prioritize suppliers with documented CAD support, comprehensive product documentation, and demonstrated experience in your target industry segment.

FAQs

How to verify robot palletizer supplier reliability?

Validate certifications (CE, ISO 9001) through official registries. Request facility videos showing active production lines and robotic testing stations. Analyze transaction history indicators such as on-time delivery rate, response speed, and verified sales volume. Third-party inspection services should be contractually permitted prior to shipment.

What is the typical MOQ and pricing range?

Standard MOQ is 1 set, with prices ranging from $6,000 for entry-level cobots to $80,000 for high-payload, fully automated systems. Pricing reflects payload capacity, axis configuration, brand of controller, and level of integration. Volume discounts may apply for orders of 5+ units.

What customization options are commonly available?

Suppliers typically offer adjustments to robotic arm reach, gripper type (vacuum, clamp, fork), conveyor interface dimensions, pallet dispensing mechanisms, strapping integration, and software logic for layer pattern sequencing. Full line design services—including CAD layouts and safety guarding—are available from leading manufacturers.

Do suppliers provide technical documentation and post-sale support?

Reputable suppliers deliver operation manuals, electrical diagrams, PLC code templates, and troubleshooting guides. Remote diagnostics and video-assisted commissioning are increasingly standard. Confirm availability of English-speaking engineers for startup support and maintenance training.

How are robot palletizers packaged and shipped internationally?

Units are crated with anti-vibration padding and moisture protection, complying with ISPM 15 for wooden packaging. Shipping options include FOB port or CIF terms, with sea freight recommended for full-container loads due to equipment weight and fragility. Air freight is viable only for lightweight cobot models.