Robotic Palletizer

Top sponsor listing

Top sponsor listing

0

0

1/25

1/25

1/3

1/3

1/3

1/3

1/12

1/12

1/18

1/18

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

CN

CN

1/3

1/3

1/3

1/3

1/20

1/20

1/7

1/7

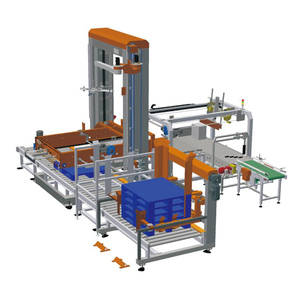

About robotic palletizer

Where to Find Robotic Palletizer Suppliers?

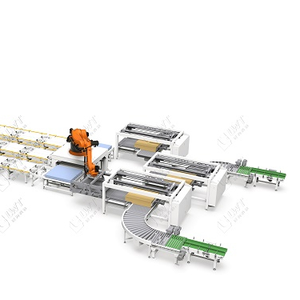

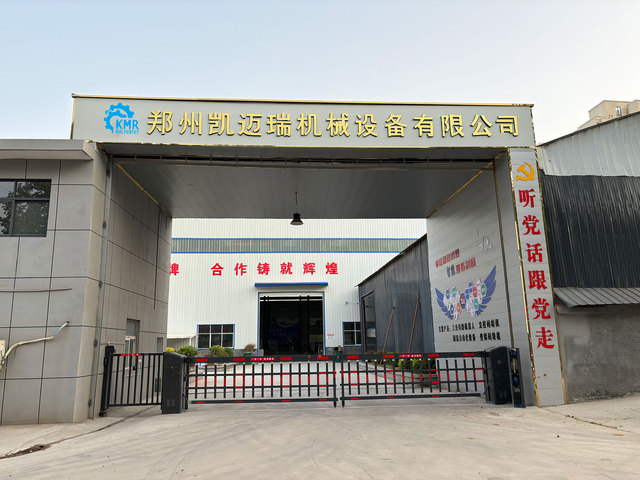

China remains the central hub for robotic palletizer manufacturing, with key supplier clusters concentrated in Shandong and Henan provinces. These regions host vertically integrated industrial ecosystems that support rapid prototyping, scalable production, and cost-efficient component sourcing. Shandong, particularly Qingdao, specializes in automated packaging lines and material handling systems, leveraging proximity to port infrastructure for streamlined global exports. Henan has emerged as a center for automation technology, supplying a high density of robotics-integrated packaging solutions supported by regional R&D incentives and engineering talent.

The clustering effect enables suppliers to maintain tight control over supply chains, reducing lead times and component procurement costs. Facilities in these zones typically operate with in-house capabilities spanning CNC machining, robotic integration, and conveyor system assembly. This integration allows standard order fulfillment within 30–45 days, with production costs averaging 20–30% below those of Western manufacturers. Buyers benefit from access to suppliers offering both standardized units and engineered-to-order systems, supported by responsive technical teams and digital design validation services such as CAD layout submissions and 3D modeling.

How to Choose Robotic Palletizer Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Technical & Engineering Capabilities

Prioritize suppliers demonstrating customization proficiency, including configurable gripper types, conveyor integration, pallet dimension adaptability, and compatibility with diverse product forms (bags, boxes, drums). Confirm availability of CAD drawings, layout planning, and labeling integration. For advanced automation needs, verify experience with collaborative robots (cobots), articulated arms, and multi-axis systems. Suppliers listing "engineering," "material size," and "package weight" as customization parameters indicate higher design flexibility.

Production & Quality Assurance

Assess operational scale through facility indicators and output capacity. While exact factory sizes are not provided, online revenue metrics offer proxy insights: one leading supplier reports over US $1.2 million in annual online revenue, indicating substantial order volume and production throughput. Target suppliers with documented on-time delivery rates exceeding 97%. All five analyzed suppliers report 100% or 97% on-time performance, suggesting strong logistical discipline. Reorder rates vary, with one supplier exceeding 22%, signaling customer retention and satisfaction.

- Response time under 2 hours is standard; three suppliers achieve ≤1 hour, reflecting efficient communication infrastructure

- Suppliers with dedicated product lines in "Packaging Line," "Conveyors," or "Articulated Robots" demonstrate domain specialization

- In-house development of strapping, dispensing, and stacking subsystems enhances system integration reliability

Procurement Risk Mitigation

Implement transaction safeguards such as staged payments and post-delivery verification. Request evidence of compliance with international standards (e.g., CE, ISO 9001), though explicit certification data is not available in public profiles. Use minimum order terms—uniformly set at 1 set or piece—as leverage for negotiation on bulk orders. Conduct virtual audits via video tours to validate production lines and quality control checkpoints before commitment.

What Are the Best Robotic Palletizer Suppliers?

| Company Name | Location | Main Product Focus | Listings in Category | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Customization Offered |

|---|---|---|---|---|---|---|---|---|

| Qingdao Ausense Packing Equipment Co., Ltd. | Shandong, CN | Packaging Line, Wrapping Machines | 15 | 97% | ≤2h | US $1,200,000+ | 22% | Yes |

| Henan Vpeks Automation Machinery Co., Ltd. | Henan, CN | Multi-Function Packaging Machines | 3 | 100% | ≤2h | US $400,000+ | <15% | No |

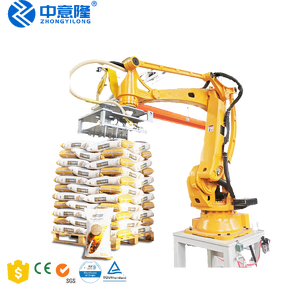

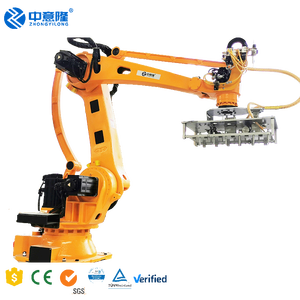

| Henan Zhong Yi Long Machinery Equipment Co., Ltd. | Henan, CN | Robot Stacker, Cobot Systems | 5 | 100% | ≤1h | US $110,000+ | <15% | Yes |

| Zaozhuang Fuliang Packaging Machinery Co., Ltd. | Shandong, CN | Column Palletizers, Industrial Robots | 5 | 100% | ≤1h | US $70,000+ | <15% | Yes |

| Guangzhou Trust Intelligent Equipment Tech. Co., Ltd. | Guangdong, CN | Collaborative Robots, Assembly Lines | 3 | 100% | ≤1h | - | - | No |

Performance Analysis

Qingdao Ausense stands out with the highest online revenue and a 22% reorder rate, indicating consistent demand and repeat business, likely driven by broad product integration across packaging lines. Despite a slightly lower on-time delivery rate (97%), its extensive customization options—including material, color, logo, and engineering specifications—suggest strong client-specific engineering support. Henan-based suppliers (Vpeks, Zhong Yi Long) and Zaozhuang Fuliang exhibit flawless on-time delivery and sub-2-hour response times, with three achieving ≤1-hour responsiveness, highlighting operational efficiency. Guangzhou Trust offers high-end cobot and 6-axis robotic systems with price points up to $46,950, positioning it for specialized industrial applications. Suppliers in Shandong and Henan dominate both volume and technical agility, making them primary candidates for mid-to-large scale automation projects.

FAQs

What is the typical price range for robotic palletizers?

Prices vary significantly based on configuration, from economical models at $900 for basic stackers to fully automated industrial systems priced between $38,000 and $46,950. Mid-range units with robotic arms and dispensers typically range from $9,500 to $13,000.

Do suppliers offer customization?

Yes, select suppliers provide comprehensive customization including gripper type, conveyor integration, pallet dimensions, packaging label placement, and material compatibility. Companies like Qingdao Ausense and Henan Zhong Yi Long explicitly list engineering and design modifications as available services.

What are common MOQ and lead time expectations?

Minimum order quantity is uniformly 1 set or piece, allowing low-volume testing. Lead times are not specified but can be estimated at 30–45 days based on industry benchmarks for similar electromechanical systems, depending on customization level and shipping method.

Are robotic palletizers compliant with international standards?

While explicit certifications (CE, ISO) are not stated in public data, suppliers advertising for global markets typically adhere to baseline safety and electromagnetic compatibility requirements. Buyers should request compliance documentation directly and verify through third-party inspection if required for import or operational use.

How to evaluate supplier reliability without onsite audits?

Leverage digital verification tools: review response times, order fulfillment history, and transaction volume. Request video demonstrations of running systems, facility walkthroughs, and sample test reports. Prioritize suppliers with high reorder rates and customization capabilities, as these reflect proven performance and technical competence.