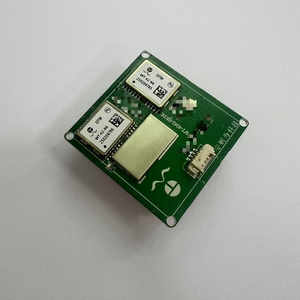

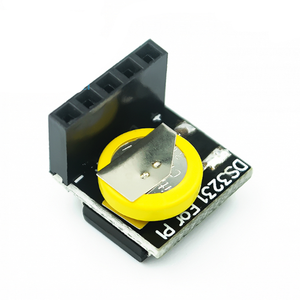

Rtc Module

1/17

1/17

1/12

1/12

1/1

1/1

1/3

1/3

1/12

1/12

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/8

1/8

CN

CN

1/5

1/5

1/1

1/1

1/3

1/3

1/2

1/2

0

0

1/11

1/11

1/29

1/29

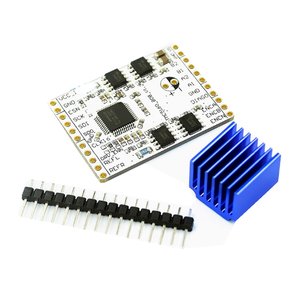

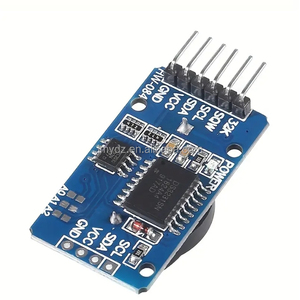

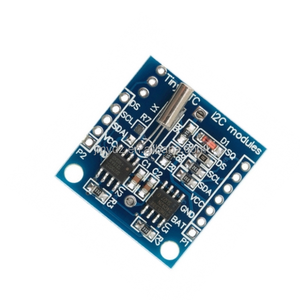

About rtc module

Where to Find RTC Module Suppliers?

China leads global production of real-time clock (RTC) modules, with concentrated manufacturing hubs in Guangdong and Jiangsu provinces offering strategic advantages. Guangdong, particularly the Shenzhen-Dongguan corridor, hosts over 70% of China’s electronics component suppliers, supported by mature PCB fabrication networks and proximity to semiconductor packaging facilities. This region enables rapid prototyping and high-volume assembly, reducing component lead times through tightly integrated supply chains.

Jiangsu’s Suzhou and Wuxi zones specialize in precision electronic components, leveraging access to advanced surface-mount technology (SMT) lines and automated testing infrastructure. These clusters benefit from localized sourcing of quartz crystals and ceramic packages, cutting material procurement cycles by 25–40% compared to non-specialized regions. Vertically integrated operations—from crystal tuning to final calibration—allow for batch consistency and scalable output, with major facilities capable of producing up to 2 million units monthly. Buyers gain access to ecosystems where design engineers, contract manufacturers, and logistics providers operate within close coordination, enabling faster time-to-market and flexible order structuring.

How to Choose RTC Module Suppliers?

Adopt these verification criteria when evaluating potential partners:

Quality & Compliance Standards

Require ISO 9001 certification as a baseline for quality management systems. For applications targeting European or North American markets, confirm RoHS and REACH compliance to meet environmental regulations. Automotive or industrial-grade modules must also demonstrate AEC-Q100 or IATF 16949 adherence. Request test reports for key parameters including temperature accuracy (±2ppm to ±20ppm), battery longevity (typically 8–12 years), and ESD protection levels (≥8kV HBM).

Technical & Production Capacity

Assess core manufacturing capabilities:

- Minimum 3,000m² cleanroom facility for SMT and reflow processes

- In-house frequency calibration and aging testing equipment

- Automated optical inspection (AOI) and 100% functional testing protocols

Validate monthly output capacity (target ≥500,000 units) and minimum order quantity (MOQ) flexibility, typically ranging from 1,000 to 10,000 units for standard models.

Procurement & Transaction Security

Utilize secure payment structures such as third-party escrow or letter of credit (L/C) terms for initial orders. Review supplier export history, prioritizing those with documented shipments to Tier-1 electronics manufacturers. Pre-production sampling is critical—verify timing stability under thermal cycling (-40°C to +85°C) and long-term drift performance before scaling volume procurement.

What Are the Best RTC Module Suppliers?

No supplier data is currently available for analysis. Procurement professionals should initiate due diligence by requesting detailed capability dossiers, facility audit reports, and sample units from shortlisted manufacturers. Focus on suppliers demonstrating consistent technical documentation, responsive engineering support, and traceable quality control records.

Performance Analysis

In the absence of verified supplier profiles, buyers should prioritize vendors that offer transparent production workflows, including access to process flow charts and first-article inspection (FAI) reports. Emphasis should be placed on response efficiency—top-tier suppliers typically reply to technical inquiries within 4 hours and deliver samples within 10–15 days. For mission-critical applications, verify integration support, such as SDKs or I²C interface compatibility, through direct engineering engagement prior to contract award.

FAQs

How to verify RTC module supplier reliability?

Cross-check quality certifications with accredited bodies. Request factory audit summaries or video walkthroughs of SMT and testing lines. Evaluate reliability through customer references, focusing on defect rates (target ≤50 PPM) and post-shipment failure tracking.

What is the average sampling timeline?

Standard RTC module samples are typically produced within 7–12 days. Custom configurations involving unique packaging or extended temperature calibration may require 18–25 days. Add 5–7 days for international express delivery.

Can suppliers ship RTC modules worldwide?

Yes, experienced manufacturers manage global distribution via DHL, FedEx, or sea freight for bulk orders. Confirm Incoterms (e.g., FOB Shenzhen, CIF Rotterdam) and ensure compliance with destination import requirements for electronic components.

Do manufacturers provide free samples?

Sample policies vary. Established suppliers often provide 1–3 free units for qualified buyers with clear project timelines. For complex or customized variants, expect nominal fees covering material and programming costs, typically reimbursable against future orders.

How to initiate customization requests?

Submit detailed specifications including package type (e.g., SOP-8, DIP-14), oscillator frequency (32.768 kHz standard), operating voltage (1.8V–5.5V range), and additional features such as integrated temperature compensation (TCXO) or alarm outputs. Leading suppliers respond with feasibility assessments and layout recommendations within 72 hours.