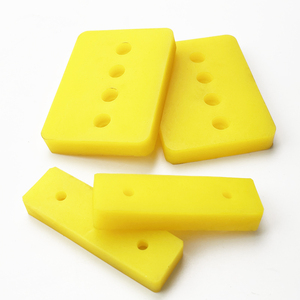

Rubber Block Producer

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

0

0

1/3

1/3

0

0

CN

CN

1/18

1/18

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

About rubber block producer

Where to Find Rubber Block Producers?

China remains the central hub for rubber block manufacturing, with key production clusters in Shandong, Hebei, and Henan provinces. These regions host vertically integrated facilities equipped with dedicated extrusion, molding, and vulcanization lines, enabling efficient mass production of custom rubber blocks. Qingdao (Shandong) and Baoding (Hebei) are notable for their concentration of ISO-registered manufacturers specializing in anti-vibration, wear-resistant, and recycled rubber products.

Suppliers in these industrial zones benefit from proximity to raw material suppliers and port logistics, reducing lead times and transportation costs. Most producers operate full in-house production cycles—from compound mixing to final packaging—supporting MOQs as low as 1 piece for prototypes and up to multi-ton bulk orders. Average monthly output across verified suppliers ranges from 50 to 500 metric tons, depending on facility scale and automation level.

How to Choose Rubber Block Producers?

Selecting a reliable rubber block producer requires verification across technical, operational, and transactional dimensions:

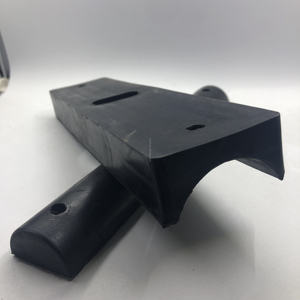

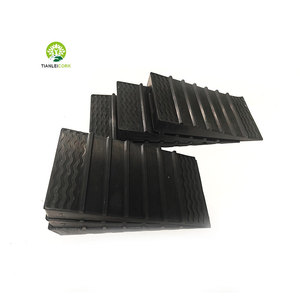

Material & Process Capabilities

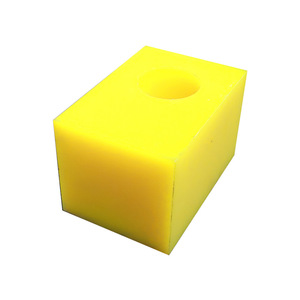

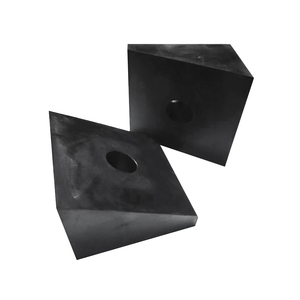

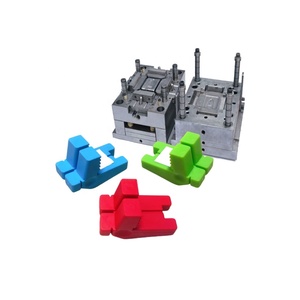

Confirm access to natural rubber, silicone, polyurethane, EPDM, and recycled compounds. Leading suppliers offer customization in hardness (Shore A 30–90), color, density, and dimensional tolerance (±0.1mm). Evaluate processing methods: compression molding for high-strength applications, injection molding for precision parts, and calendering for sheet-based derivatives.

Quality Assurance Systems

Prioritize suppliers with documented quality management systems. While formal ISO 9001 certification is not universally listed, consistent on-time delivery (>90%) and third-party testing reports for tensile strength, compression set, and aging resistance serve as practical proxies. For export markets, compliance with RoHS, REACH, or FDA standards may be required based on end-use.

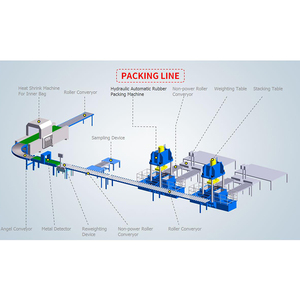

Production Infrastructure Verification

Assess scalability through measurable indicators:

- Own production line ownership confirmed via factory videos or audits

- Custom tooling and mold-making capabilities for OEM designs

- In-house R&D support for material formulation adjustments

Cross-reference response time (target ≤3 hours) and reorder rates (>30%) as indicators of customer satisfaction and operational stability.

What Are the Best Rubber Block Producers?

| Company Name | Location | Main Materials | Customization | MOQ Range | On-Time Delivery | Avg. Response | Reorder Rate | Annual Online Revenue |

|---|---|---|---|---|---|---|---|---|

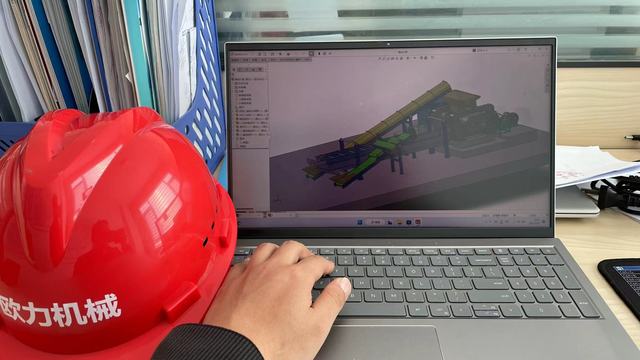

| Qingdao Ouli Machine Co., Ltd. | Shandong, CN | Rubber, Steel, Fiber Composites | Full design, size, logo, pressure, capacity | Varies by product | 100% | ≤3h | 50% | US $1.9M+ |

| Huixian Qianjin Rubber Co., Ltd. | Henan, CN | Polyurethane, Natural Rubber | Vibration isolators, silent blocks, molded shapes | 50–1,000 pieces | 92% | ≤8h | <15% | US $30,000+ |

| Hebei Sunrise Rubber & Plastic Technology Co., Ltd. | Hebei, CN | Silicone, Wear-Resistant Rubber, Plastic Blends | Size, shape, wear resistance, automotive-grade specs | 50–500 pieces / 50kg | 100% | ≤1h | 33% | US $140,000+ |

| Xinxiang City Ding Cheng Rubber And Plastic Co., Ltd. | Henan, CN | Natural, Silicone, Anti-Vibration Compounds | Shock absorbers, protective mounts, damping blocks | 1–200 pieces | 27% | ≤6h | 30% | US $100,000+ |

| Baytain Rubber And Plastic Products Co., Ltd. | Shandong, CN | High-Wear Resistant Rubber (Ball Mill Bushings) | Industrial bushings, mill liners, heavy-duty blocks | 10 pieces | 100% | ≤2h | <15% | US $100+ |

Performance Analysis

Qingdao Ouli Machine and Hebei Sunrise stand out with 100% on-time delivery, sub-3-hour response times, and strong reorder rates, indicating robust production control and customer service. Qingdao Ouli’s extensive customization scope—including full machinery integration (mills, calenders, conveyors)—positions it as a strategic partner for engineered rubber solutions. Hebei Sunrise offers competitive pricing ($0.30/unit) and fast prototyping, ideal for high-volume industrial buyers.

Baiyin and Huixian Qianjin demonstrate niche specialization: Baiyin in ultra-durable rubber components for mining and cement mills, and Huixian in polyurethane silent blocks. However, Xinxiang Ding Cheng’s 27% on-time delivery rate signals potential fulfillment risks despite broad product diversity. Buyers should prioritize suppliers with proven track records in both technical execution and logistical reliability for mission-critical applications.

FAQs

How to verify rubber block producer reliability?

Request evidence of in-house production, including process flowcharts, equipment lists, and facility videos. Validate performance metrics such as on-time delivery and reorder rate against transaction history. For regulated industries, require material test reports (MTRs) and compliance documentation.

What is the typical lead time for rubber block orders?

Standard orders take 15–25 days after sample approval. Custom molds add 7–14 days. Rush production is available from select suppliers within 10–12 days at a premium. Air freight adds 5–7 days for international delivery.

Can rubber block producers handle small MOQs?

Yes, several suppliers accept MOQs as low as 1 piece for samples or prototyping. Full production runs typically start at 50–500 pieces, with unit cost decreasing significantly beyond 1,000 units.

Do manufacturers provide free samples?

Sample policies vary. Some suppliers offer free samples for qualified buyers committing to future volume orders. Others charge a nominal fee (often refundable upon order placement). Expect shipping costs to apply unless otherwise negotiated.

How to initiate customization requests?

Submit detailed specifications including material type, Shore hardness, dimensions, operating environment (temperature, load, vibration), and application context. Reputable producers will respond with technical validation, CAD drawings, and prototype timelines within 72 hours.