Sandf Supplier Database Application Forms

1/3

1/3

1/30

1/30

1/10

1/10

CN

CN

1/18

1/18

1/17

1/17

About sandf supplier database application forms

Where to Find Sandf Supplier Database Application Forms Suppliers?

Manufacturers of abrasive tools and industrial forms linked to the "sandf" category are primarily concentrated in key industrial provinces across China, including Shandong, Guangdong, and Hubei. These regions host specialized clusters for abrasives and construction materials production, supported by mature supply chains for silicon carbide, aluminum oxide, and waterproof backing substrates. Shandong and Guangdong alone account for over 40% of China’s export-oriented abrasive tool manufacturers, benefiting from proximity to major ports and integrated material processing facilities.

The regional ecosystems enable vertical integration—from raw material sourcing to precision coating and die-cutting—reducing component lead times and enabling rapid fulfillment of both standard and customized orders. Suppliers in these zones typically operate within 50km of substrate, adhesive, and polymer suppliers, allowing for just-in-time production models. This localization reduces manufacturing costs by 15–25% compared to non-specialized regions and supports MOQ flexibility, with some facilities capable of fulfilling trial batches as low as 10 pieces. Average production lead times range from 15 to 30 days, depending on customization level and order volume.

How to Choose Sandf Supplier Database Application Forms Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Product & Material Specifications

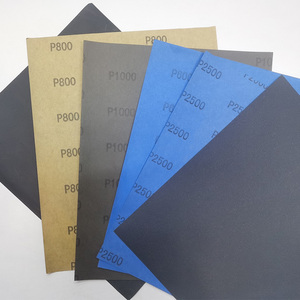

Confirm the use of appropriate abrasive compounds (e.g., silicon carbide for wet applications, aluminum oxide for durability) and backing materials (waterproof paper, polyester film, or latex-coated foam). Verify grain size consistency (e.g., P36–P600) and bonding methods (resin-over-resin or heat-cured adhesives) to ensure performance alignment with intended use cases such as metallographic analysis or surface finishing.

Quality Assurance Protocols

Prioritize suppliers with documented quality control systems. While formal ISO 9001 certification is not universally listed, consistent on-time delivery rates (≥97%) and verifiable testing procedures indicate operational discipline. Evaluate response to defect claims and availability of batch-specific inspection reports. For international buyers, compliance with RoHS or REACH standards may be required for market entry in Europe or North America.

Production and Customization Capacity

Assess capabilities through the following indicators:

- Minimum Order Quantity (MOQ) flexibility: Ranges observed from 10 to 10,000 units, signaling adaptability for sample testing or bulk procurement

- In-house printing, cutting, and packaging: Critical for custom labeling, branding, or form layout adjustments

- OEM/ODM support: Verified through logo application, color coding, and specification-based design services

Cross-reference online revenue metrics (where available) with reorder rates to gauge customer retention and product reliability. Suppliers with higher reorder rates (>25%) often demonstrate stronger quality consistency and service responsiveness.

Transaction Risk Mitigation

Utilize secure payment frameworks that align with international trade standards. Request pre-shipment product samples to validate material integrity and dimensional accuracy against specifications. Confirm packaging methods (e.g., vacuum-sealed sets or moisture-resistant wrapping) to prevent degradation during transit, particularly for waterproof grades. Leverage response time benchmarks (≤5 hours average among top-tier suppliers) as a proxy for post-order support efficiency.

What Are the Best Sandf Supplier Database Application Forms Suppliers?

| Company Name | Main Products | Price Range (per unit) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| Jinan F.H. International Co., Ltd. | Abrasive Tools, Wood Pellet Mills, Biomass Machines | $0.02–$0.04 | 10–100 pcs | 100% | ≤2h | <15% | US $120,000+ |

| Shanghai Abrasive Tools Co., Ltd. | Abrasive Tools, Polishing Pads, Drill Bits, Saw Blades | $0.10–$11.54 | 1 set – 10,000 pcs | 100% | ≤7h | <15% | US $750,000+ |

| Guangdong Qisheng Abrasive Technology Co., Ltd | Abrasive Tools, Sanding Discs | $0.04–$0.45 | 500–10,000 pcs | 100% | ≤2h | 44% | US $20,000+ |

| Qingdao H&F Trading Co., Ltd. | Aluminum Formwork, Construction Accessories | $0.03–$20.00 | 2–100 pcs | 100% | ≤5h | 28% | US $120,000+ |

| Hubei Zhongchen Electronic Abrasives Co., Ltd. | Abrasive Tools, Sanding Discs, Power Tools | $0.04–$0.17 | 1–100 pcs | 100% | ≤5h | 25% | US $60,000+ |

Performance Analysis

Jinan F.H. International and Shanghai Abrasive Tools demonstrate high-volume export capability with strong online revenue and strict on-time delivery records. Guangdong Qisheng stands out with a 44% reorder rate—the highest in the dataset—indicating robust customer satisfaction despite lower overall sales volume. Qingdao H&F distinguishes itself through extensive customization options, including design, color, and material modifications, making it suitable for specialized form requirements. Hubei Zhongchen offers the lowest MOQs (down to 1 piece), providing flexibility for prototyping and small-batch trials. All five suppliers maintain 100% on-time delivery performance, suggesting reliable logistics execution and order management systems.

FAQs

How to verify sandf supplier database application forms supplier reliability?

Evaluate suppliers based on delivery consistency, response speed, and reorder metrics. Request evidence of quality control processes, such as batch testing or material certifications. Conduct virtual audits via facility videos or third-party inspection reports to confirm production authenticity.

What is the typical MOQ for abrasive forms and sandpaper sheets?

MOQ varies significantly: standard items may require 100–10,000 pieces, while select suppliers offer down to 10 or even single-piece orders for sample validation. Custom-formatted or branded products typically require minimum runs of 500 units or more.

Can suppliers customize application forms and packaging?

Yes, multiple suppliers offer OEM services including logo imprinting, custom color coding, tailored sheet dimensions, and specific grit configurations. Qingdao H&F explicitly lists design, drawing, and packaging customization as available options.

What are common lead times for production and shipping?

Production lead times average 15–30 days post-approval of specifications. Air freight adds 5–10 days for international delivery, while sea freight ranges from 20–40 days depending on destination. Expedited processing may be available for urgent orders.

Do suppliers provide free samples?

Sample availability depends on product type and supplier policy. Some offer low-cost samples (e.g., $0.04–$0.17 per unit) with minimal MOQ (1–100 pieces), effectively serving as paid test runs. Full cost reimbursement is uncommon unless tied to subsequent large-volume contracts.