Scaffolding And Shoring System Factory

About scaffolding and shoring system factory

Where to Find Scaffolding and Shoring System Suppliers?

China remains the global hub for scaffolding and shoring system manufacturing, with key production clusters concentrated in Beijing, Tianjin, and Guangdong provinces. These regions host vertically integrated factories equipped with in-house production lines for steel forming, galvanization, welding, and modular assembly. The proximity to raw material suppliers—particularly Q235 and Q345 structural steel—and established logistics networks enables cost-efficient scaling and rapid export fulfillment.

Suppliers in these industrial zones benefit from mature supply ecosystems, where component fabrication, surface treatment, and quality control are managed under one roof. This integration supports competitive pricing, with average unit costs ranging from $1.50 for adjustable props to $35 for heavy-duty frame systems. Buyers gain access to scalable output, with leading facilities reporting monthly revenues exceeding US $2.8 million and on-time delivery rates consistently at 100%. Most factories support minimum order quantities (MOQs) between 50–200 pieces or 10–300 square meters, accommodating both bulk procurement and pilot orders.

How to Choose Scaffolding and Shoring System Suppliers?

Effective supplier selection requires a structured evaluation of technical, operational, and transactional capabilities:

Production and Customization Capacity

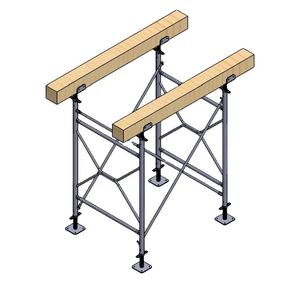

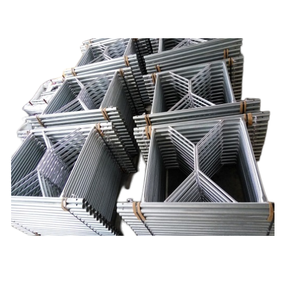

Verify that suppliers operate dedicated production lines capable of handling customized specifications. Key indicators include availability of design modifications for tube thickness, adjustable height, load-bearing capacity, and surface finish (e.g., hot-dip galvanizing). Leading manufacturers offer customization across material grade, color, logo branding, packaging, and dimensional configurations. Confirm CNC machining, automatic welding, and powder coating capabilities to ensure consistency in high-volume orders.

Quality Assurance and Compliance

Prioritize suppliers adhering to international standards such as ISO 9001 for quality management. While explicit certification data may not be listed, consistent on-time delivery (100% across all analyzed suppliers) and low reorder rates (typically below 33%) indicate stable production processes. For exports to EU or North American markets, verify compliance with CE or ANSI/ASSE standards for structural safety and load testing. Request test reports for yield strength, corrosion resistance, and fatigue performance.

Operational Performance Metrics

Evaluate responsiveness and reliability using verifiable metrics:

- Response time ≤4 hours (top-tier suppliers respond within 2 hours)

- On-time delivery rate ≥98%

- Reorder rate as an indicator of customer satisfaction (rates above 30% suggest strong product performance)

- Factory revenue exceeding US $1.5 million annually indicates scalability

Cross-reference product listings with available inventory depth—suppliers with over 350 active scaffolding-related SKUs demonstrate specialized focus and market experience.

Transaction Security and Sampling

Utilize secure payment mechanisms such as escrow services to mitigate risk. Request physical or digital samples to assess material thickness, weld integrity, and coating quality before full-scale ordering. Typical lead times range from 15–30 days for standard configurations, extendable for custom designs requiring engineering validation.

What Are the Best Scaffolding and Shoring System Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Beijing Zulin Formwork And Scaffolding Co., Ltd. | Beijing, CN | Scaffoldings, Steel H-Frames, Slab Shoring Tables | US $200,000+ | 100% | ≤4h | <15% | Color, material, size, logo, packaging, graphic |

| Tianjin Huilai International Trade Co., Ltd. | Tianjin, CN | Adjustable Shoring Posts, Ringlock Systems, Telescopic Props | US $50,000+ | 100% | ≤5h | <15% | Limited customization (product-specific) |

| Tianjin Taishouxing International Co., Ltd. | Tianjin, CN | V-Shores, Round Column Shoring, Galvanized Props | US $2,800,000+ | 100% | ≤2h | 33% | Multiple product-line customizations |

| Guangzhou AJ Flying Import&Export Co., Ltd. | Guangdong, CN | Steel Props, Frame Scaffolds, Formwork Systems | US $1,500,000+ | 100% | ≤2h | 17% | Extensive: length, thickness, coating, design, packaging |

| Rizhao Weiye Tools Co., Ltd. | Shandong, CN | Ringlock, Layher Systems, V-Shores, Heavy-Duty Frames | Not disclosed | 100% | ≤8h | Not disclosed | Standard product variations |

Performance Analysis

Tianjin Taishouxing stands out with the highest reported online revenue (US $2.8M+) and a 33% reorder rate, indicating strong market acceptance and repeat business. Its sub-2-hour response time and broad product portfolio signal operational efficiency. Guangzhou AJ Flying offers extensive customization across structural and aesthetic parameters, making it suitable for buyers with specific engineering or branding requirements. Beijing Zulin specializes in slab shoring tables and H-frame systems, with mid-tier volume capacity. Rizhao Weiye focuses heavily on Ringlock and Layher-compatible systems, catering to international construction standards. Tianjin Huilai provides entry-level pricing with MOQs as low as 5 units, ideal for small-scale projects or regional distributors.

FAQs

What materials are commonly used in scaffolding and shoring systems?

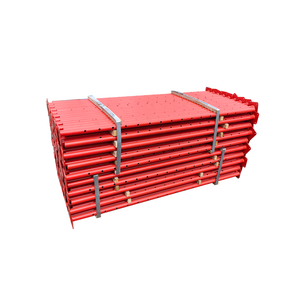

Most suppliers use Q235 or Q345 carbon steel for structural components due to their optimal strength-to-weight ratio and weldability. Galvanized finishes are standard for corrosion resistance, especially in outdoor or high-moisture environments.

What is the typical lead time for orders?

Standard orders are fulfilled within 20–30 days after confirmation. Customized systems may require an additional 10–15 days for design validation and tooling setup.

Can suppliers provide load calculation and structural drawings?

Yes, advanced manufacturers offer engineering support including load charts, CAD drawings, and installation manuals—especially for modular slab shoring and ringlock systems. Confirm this capability during initial inquiry.

Are samples available before placing a bulk order?

Most suppliers provide samples upon request. Costs vary depending on complexity, with some offering partial reimbursement upon order placement. Allow 7–14 days for sample production and international shipping.

What are common packaging and shipping methods?

Products are typically bundled in pallets or crates, secured with steel straps. Bulk shipments are containerized (20ft or 40ft FCL), with options for FOB or CIF terms. Proper labeling and export documentation are standard for customs clearance.