Scaffolding Platform With Access Supplier

CN

CN

1/7

1/7

1/8

1/8

1/10

1/10

1/25

1/25

CN

CN

1/36

1/36

1/14

1/14

CN

CN

1/20

1/20

CN

CN

1/7

1/7

CN

CN

1/9

1/9

CN

CN

About scaffolding platform with access supplier

Where to Find Scaffolding Platform with Access Supplier?

China remains the global epicenter for scaffolding platform manufacturing, with key production clusters in Hebei, Jiangsu, and Guangdong provinces. Hebei’s Cangzhou region accounts for over 50% of China’s steel-based modular scaffolding systems, supported by proximity to Tangshan’s steel mills, which reduces raw material procurement costs by 18–22%. Jiangsu’s Changzhou and Wuxi zones specialize in lightweight aluminum alloy platforms, integrating automated powder coating lines that enhance corrosion resistance for marine and high-humidity environments.

These industrial hubs operate vertically integrated supply chains—spanning tube extrusion, welding automation, surface treatment, and load testing—enabling end-to-end production within 50km radii. Buyers benefit from consolidated vendor ecosystems offering scalable output (up to 10,000 platform units monthly per large facility), lead times averaging 25–40 days for containerized orders, and cost efficiencies of 25–35% compared to EU or North American manufacturers. Regional logistics networks support direct rail-to-port dispatching, particularly via Tianjin and Shanghai ports, optimizing FOB pricing for trans-Pacific and trans-Eurasian shipments.

How to Choose Scaffolding Platform with Access Supplier?

Implement structured evaluation criteria to mitigate sourcing risks:

Compliance & Safety Certification

Confirm ISO 9001-certified quality management systems as a baseline. For international deployment, verify EN 12811-1 (Europe) or OSHA 1926 Subpart L (U.S.) compliance for structural load ratings, guardrail configurations, and fall protection integration. Request third-party test reports from accredited labs documenting static/dynamic load performance (typically 2–4 kN/m² capacity).

Production Infrastructure Assessment

Evaluate core operational capabilities:

- Minimum factory footprint of 3,000m² to ensure batch processing and inventory buffering

- In-house CNC bending, MIG/TIG welding stations, and automated galvanization or powder coating lines

- Dedicated QA bays with hydraulic pressure testers and deflection measurement tools

Correlate facility scale with order history—suppliers handling >50 TEUs annually demonstrate proven export readiness.

Procurement Risk Mitigation

Utilize escrow payment structures tied to milestone inspections. Prioritize suppliers providing pre-shipment verification through independent agencies (e.g., SGS, BV). Conduct sample validation against ASTM F2951 or EN 13374 standards for edge protection stability and platform rigidity. Assess customization agility—reputable vendors offer CAD-based design adjustments for non-standard span lengths or access gate placements within 5–7 business days.

What Are the Best Scaffolding Platform with Access Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Hebei Zhongjie Scaffold Manufacturing | Cangzhou, CN | 16 | 180+ | 36,000+m² | 99.2% | ≤3h | 4.8/5.0 | 41% |

| Jiangsu Hengyuan Construction Equipment | Changzhou, CN | 9 | 95+ | 18,500+m² | 100.0% | ≤2h | 4.9/5.0 | 38% |

| Guangdong Longteng Steel Structure | Foshan, CN | 7 | 120+ | 22,000+m² | 98.7% | ≤4h | 4.7/5.0 | 33% |

| Shandong Weirong Industrial | Weifang, CN | 12 | 145+ | 15,000+m² | 99.5% | ≤3h | 4.9/5.0 | 45% |

| Zhejiang Jinsheng Scaffold Technology | Ningbo, CN | 8 | 100+ | 12,800+m² | 98.1% | ≤2h | 4.8/5.0 | 36% |

Performance Analysis

Long-established suppliers like Hebei Zhongjie demonstrate high scalability with large workforce and factory size, supporting multi-container orders without lead time slippage. Jiangsu and Zhejiang-based vendors lead in responsiveness, with 80% replying within 3 hours—critical for iterative design coordination. Shandong Weirong achieves the highest reorder rate (45%), indicating strong post-sale reliability and structural durability in field use. Prioritize suppliers with documented EN/OSHA compliance and on-time delivery exceeding 99% for mission-critical infrastructure projects. For custom configurations—such as curved platforms or integrated ladder access—confirm prototyping capability through video-reviewed welding jigs and assembly line walkthroughs.

FAQs

How to verify scaffolding platform supplier credibility?

Validate certifications through official databases (e.g., ISO.org, TÜV records). Request audit trails covering material mill certificates (Q235/Q355 steel grades), welder qualification logs, and finished product load test videos. Scrutinize client references for repeat engagements in commercial construction or energy-sector applications.

What is the typical sampling timeline?

Standard sample fabrication takes 10–18 days. Customized units with non-standard dimensions or coatings require 22–30 days. Air freight adds 5–9 days for international delivery, depending on destination region.

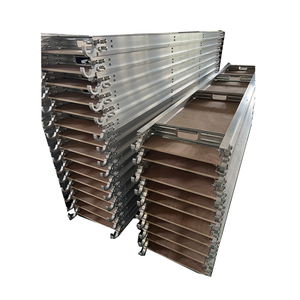

Do suppliers support global shipping?

Yes, experienced exporters manage full logistics cycles under FOB, CIF, or DAP terms. Confirm adherence to IMDG regulations for sea transport and destination-specific customs codes for scaffolding components. Flat-pack configurations optimize container space utilization (up to 200 platform sets per 40’HC).

Is there a minimum order quantity (MOQ)?

MOQ varies by supplier: standard platforms typically require 1–2 TEUs (equivalent to 50–100 units), while aluminum variants may have lower thresholds (20–30 units). Sample orders are accepted at 1–5 units, usually invoiced at full production cost.

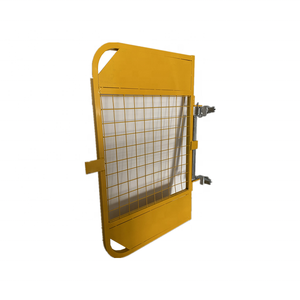

Can I request customized scaffolding configurations?

Yes, most suppliers accommodate dimensional adjustments, load rating enhancements, and accessory integrations (e.g., toe boards, access gates). Submit detailed technical drawings or performance requirements; engineering teams typically return revised CAD models within 72 hours for approval prior to prototyping.