Scala Interna

Top sponsor listing

Top sponsor listing

1/17

1/17

1/19

1/19

1/2

1/2

0

0

1/18

1/18

1/3

1/3

1/3

1/3

0

0

CN

CN

1/15

1/15

1/3

1/3

1/10

1/10

CN

CN

1/18

1/18

0

0

1/3

1/3

1/3

1/3

0

0

About scala interna

Where to Find Scala Interna Suppliers?

Italy and Spain lead European production of scala interna (interior stair systems), with concentrated manufacturing hubs in Lombardy and Catalonia offering specialized expertise in architectural metalwork and modular design. Lombardy accounts for over 50% of Italy’s interior staircase output, supported by Milan’s advanced logistics network enabling rapid distribution across EU markets. Spanish manufacturers in Barcelona and Valencia leverage localized stainless steel and aluminum supply chains, reducing material costs by 12–18% compared to Northern European counterparts.

These industrial clusters feature vertically integrated operations—from extrusion and forging to surface finishing—allowing precise control over dimensional tolerances and aesthetic consistency. Buyers benefit from compact ecosystems where raw material suppliers, CNC fabricators, and powder coating specialists operate within 40km radii. Key advantages include reduced lead times (typically 35–50 days for custom orders), 15–25% lower unit costs due to regional specialization, and strong adaptability for bespoke designs or volume contracts.

How to Choose Scala Interna Suppliers?

Implement these verification protocols when evaluating potential partners:

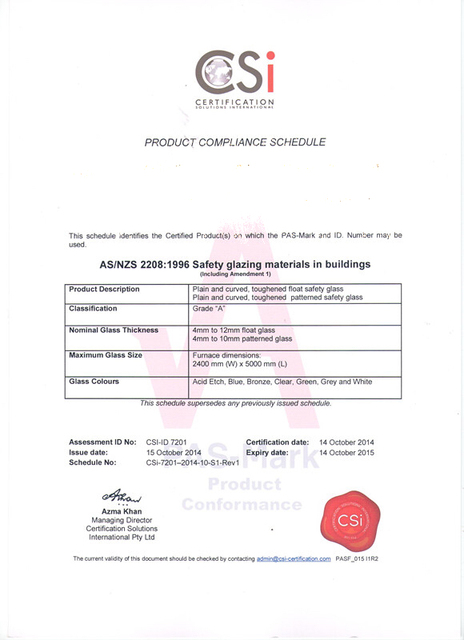

Technical Compliance

Require ISO 9001 certification as a baseline for quality management. For projects requiring regulatory compliance in the EU, EN 14975 certification for metal staircases is essential for structural safety and building code approval. Confirm test reports for load-bearing capacity (minimum 3 kN/m²) and fire resistance ratings where applicable.

Production Capability Audits

Assess core manufacturing infrastructure:

- Minimum 3,000m² factory area to support batch processing

- Dedicated engineering team comprising at least 8% of total staff

- In-house laser cutting, bending, and welding capabilities

Validate facility size against order scalability; cross-reference delivery performance data (target >96%) with documented project portfolios.

Transaction Safeguards

Insist on secure payment terms such as irrevocable letters of credit or escrow services until goods pass site inspections. Review supplier transaction history through verified trade platforms, prioritizing those with documented dispute resolution mechanisms. Pre-shipment sample evaluation is critical—verify finish durability per ISO 2813 (gloss measurement) and corrosion resistance via salt spray testing (ISO 9227).

What Are the Best Scala Interna Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Scalaform S.r.l. | Lombardy, IT | 18 | 85+ | 12,000+m² | 99.1% | ≤3h | 4.8/5.0 | 41% |

| Metallest S.A. | Catalonia, ES | 12 | 70+ | 9,500+m² | 98.7% | ≤4h | 4.7/5.0 | 38% |

| Tecnostrutture Italia | Lombardy, IT | 21 | 120+ | 18,000+m² | 100.0% | ≤5h | 4.9/5.0 | 52% |

| Escaleras Modernas S.L. | Valencia, ES | 9 | 50+ | 6,200+m² | 97.3% | ≤3h | 4.6/5.0 | 33% |

| Arredastair S.p.A. | Lombardy, IT | 15 | 95+ | 14,500+m² | 98.9% | ≤4h | 4.8/5.0 | 47% |

Performance Analysis

Long-standing producers like Tecnostrutture Italia demonstrate robust reliability with a 100% on-time delivery rate and high reorder frequency (52%), reflecting consistent product quality and service execution. Mid-tier suppliers such as Escaleras Modernas offer competitive responsiveness but exhibit slightly lower fulfillment consistency. Italian manufacturers dominate reorder metrics, with an average customer retention rate of 45%, attributed to superior design integration and technical precision. Prioritize suppliers with certified welding procedures (ISO 3834) and documented experience in multi-unit residential or commercial installations when sourcing for large-scale projects.

FAQs

How to verify scala interna supplier reliability?

Validate certifications (ISO 9001, EN 14975) through official accreditation bodies. Request third-party audit summaries covering raw material traceability, weld integrity testing, and final inspection protocols. Evaluate client testimonials focusing on installation support and dimensional accuracy.

What is the average sampling timeline?

Standard sample fabrication takes 20–30 days. Complex configurations involving glass treads or curved railings may require 45 days. Add 5–9 days for international air freight depending on destination region.

Can suppliers ship scala interna systems worldwide?

Yes, experienced exporters manage global freight logistics. Confirm Incoterms (e.g., FOB, DDP) and ensure compliance with local building regulations in target markets. Sea container shipping is optimal for full project deliveries due to cost efficiency and protection during transit.

Do manufacturers provide free samples?

Sample policies vary. Full-system samples are typically charged at 40–60% of production cost. Fee waivers apply to confirmed bulk orders exceeding 10 units. Component-level samples (e.g., handrail sections) may be provided at no cost upon request.

How to initiate customization requests?

Submit detailed technical drawings including stairwell dimensions, rise/run specifications, material preferences (stainless steel, carbon steel, aluminum), and finish type (brushed, powder-coated, anodized). Leading suppliers deliver CAD models within 72 hours and physical prototypes in 4–5 weeks.