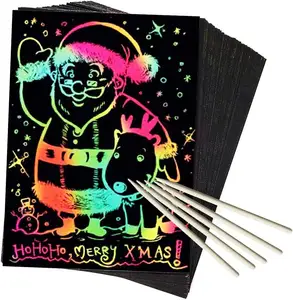

Scratch Games

1/26

1/26

1/3

1/3

1/2

1/2

1/16

1/16

1/25

1/25

1/3

1/3

1/34

1/34

1/3

1/3

1/3

1/3

1/14

1/14

1/32

1/32

1/29

1/29

1/26

1/26

1/17

1/17

1/24

1/24

0

0

1/36

1/36

About scratch games

Where to Find Scratch Games Suppliers?

China remains the dominant hub for scratch games manufacturing, with key production clusters concentrated in Guangdong and surrounding regions. These areas host vertically integrated printing and card production facilities specializing in both paper-based and plastic substrate solutions. Shenzhen and Guangzhou serve as primary centers for high-end, customizable scratch cards, leveraging proximity to material suppliers and export ports like Shekou and Nansha, which streamline logistics for global distribution.

The industrial ecosystem supports rapid prototyping and scalable batch production, enabling suppliers to fulfill orders ranging from 100 to over 50,000 units efficiently. Manufacturers utilize offset printing, UV coating, hot stamping, and tamper-evident scratch-off layer application to ensure product integrity and visual appeal. Economies of scale, combined with localized access to PVC, synthetic paper, aluminum-based coatings, and ink formulations, allow for competitive pricing—often 20–40% below Western market rates—while maintaining technical compliance for international retail and promotional use.

How to Choose Scratch Games Suppliers?

Selecting reliable partners requires a structured evaluation based on production capability, quality assurance, and transactional reliability:

Material & Production Expertise

Verify that suppliers offer appropriate substrate options: paper (CR80 standard common), PVC, or composite materials for durability. Confirm in-house capabilities in digital/offset printing, spot UV, lamination, and precision die-cutting. For waterproof or scratch-resistant variants, assess availability of protective lacquers and laminated finishes. Suppliers with dedicated R&D teams can support custom security features such as serialized codes, holographic overlays, or RFID integration.

Quality Management Systems

Prioritize manufacturers with documented quality control processes. While formal ISO 9001 certification is not universally listed, evidence of consistent on-time delivery (>95%), low defect rates, and internal inspection protocols should be verified. Look for suppliers who conduct pre-shipment inspections and provide sample validation before mass production.

Customization and Compliance

Evaluate flexibility in design personalization including logo placement, color schemes, size variations (standard 85.6×54mm or custom dimensions), and packaging configurations. Ensure compliance with regional safety standards (e.g., RoHS, non-toxic inks) when distributing in EU or North American markets. Request printed samples to verify scratch layer opacity, ease of removal, and print clarity.

Transaction Reliability Indicators

Use response time, reorder rate, and order fulfillment metrics as proxies for operational efficiency:

- Response time ≤1 hour indicates strong customer service infrastructure

- On-time delivery rates ≥99% correlate with robust production planning

- Reorder rates above 20% suggest client satisfaction and product consistency

- Minimum Order Quantity (MOQ) flexibility—from 100 to 5,000 units—enables testing and small-batch procurement

What Are the Best Scratch Games Suppliers?

| Company Name | Main Materials | Price Range (USD) | MOQ | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Tophonesty Smart Card Technology Co., Ltd. | PVC, Plastic, Titanium | $0.04–0.40 | 100 pcs | 99% | ≤1h | 18% | Color, material, size, logo, packaging, graphic | US $80,000+ |

| Rubymarche Limited | Paper | $0.02–0.03 | 5,000 pcs | - | ≤3h | - | Limited (bulk focus) | - |

| HK REDGIANT IOT TECH CO., LIMITED | Paper, CR80 | $0.03–0.20 | 100–500 pcs | 100% | ≤4h | 16% | UV spot, gift design, reward points | US $60,000+ |

| Guangzhou Zhichuang Printing Factory | Paper | $0.01 | 100–500 pcs | 87% | ≤3h | 28% | Color, material, size, logo, packaging, graphic | US $40,000+ |

| Xiong'an Rongda Trading Co., Ltd. | Paper | $0.01–0.22 | 100–500 pcs | 100% | ≤1h | 24% | Pattern printing, scratch-off layout | US $20,000+ |

Performance Analysis

Shenzhen Tophonesty stands out for premium material offerings—including titanium and RFID-enabled cards—and strong customization breadth, supported by fast response times and high transaction volume. HK REDGIANT and Xiong'an Rongda demonstrate perfect on-time delivery records, with MOQs accessible to SMEs and startups. Guangzhou Zhichuang offers the lowest unit pricing at $0.01, ideal for high-volume promotional campaigns, though its 87% on-time delivery rate warrants closer shipment monitoring. Rubymarche targets budget-conscious buyers with ultra-low-cost paper cards but imposes higher MOQs (5,000+ units) and lacks performance transparency, increasing procurement risk for time-sensitive projects.

FAQs

What is the typical lead time for scratch games production?

Standard orders take 7–15 days for production, depending on complexity and customization level. Add 3–7 days for quality checks and packaging. Air freight shipping adds 5–10 days internationally; sea freight requires 20–35 days for full container loads.

Do suppliers offer free samples?

Many suppliers provide physical or digital proofs at no cost. Actual sample units may be free for qualified buyers or require partial cost recovery, especially for customized designs. Expect 3–7 days for sample production and 5–10 days for delivery via express courier.

Can scratch games be customized with unique security features?

Yes. Leading suppliers support serialization, QR codes, PIN masking, and encrypted data layers. Advanced options include holographic foils, microprinting, and tamper-evident coatings to prevent fraud in lottery or voucher applications.

What are common materials used in scratch game manufacturing?

Paper (coated cardstock) is most common for low-cost promotions. PVC and synthetic composites are preferred for durable, reusable cards such as loyalty or membership tokens. Aluminum-based scratch-off coatings are standard for concealing hidden values.

How do I negotiate better pricing with suppliers?

Leverage volume commitments—orders exceeding 10,000 units typically secure discounts of 10–25%. Consolidate design elements across batches to reduce setup costs. Request bundled services (design, printing, packaging) for added savings. Establish long-term contracts to lock in favorable rates and priority scheduling.