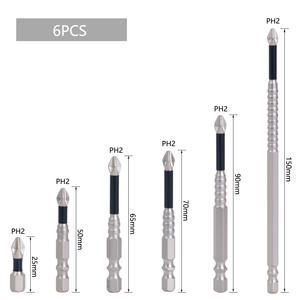

Screwdriver Bits Set

Top sponsor listing

Top sponsor listing

1/9

1/9

0

0

1/30

1/30

0

0

1/3

1/3

1/3

1/3

1/1

1/1

1/6

1/6

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/28

1/28

1/3

1/3

0

0

0

0

About screwdriver bits set

Where to Find Screwdriver Bits Set Suppliers?

China remains a dominant hub for screwdriver bits set manufacturing, with key production clusters in Anhui, Zhejiang, Guangdong, and Sichuan provinces. These regions host vertically integrated hardware tool ecosystems, combining precision machining, heat treatment facilities, and packaging lines within compact industrial zones. Anhui and Zhejiang specialize in high-volume consumer-grade tool sets, while Guangdong and Sichuan focus on mid-to-high-end precision and impact-grade bits used in electronics and industrial applications.

Suppliers benefit from localized supply chains for S2 alloy steel, chrome vanadium (CRV), and stainless steel—core materials for durable bit performance. Proximity to material sources reduces lead times by 10–15% compared to offshore alternatives. Industrial clusters also support rapid prototyping and small-batch customization, enabling MOQs as low as 2–100 sets depending on complexity. Buyers gain access to agile production networks capable of fulfilling orders within 15–30 days on average, with online transaction histories indicating consistent on-time delivery rates above 95%.

How to Choose Screwdriver Bits Set Suppliers?

Effective supplier selection requires systematic evaluation across three critical dimensions:

Quality Assurance & Compliance

Prioritize suppliers demonstrating adherence to international quality benchmarks. While ISO 9001 certification is not universally listed, performance metrics such as 97–100% on-time delivery and reorder rates up to 22% serve as indirect indicators of process reliability. For export markets requiring regulatory compliance, verify RoHS or CE marking capabilities, especially for sets marketed toward EU or North American consumers. Magnetic tip retention, torque resistance, and surface hardness (HRC 58–62) should be documented through internal testing protocols.

Production and Customization Capacity

Assess technical flexibility based on available customization options and product range. Leading suppliers offer configurable parameters including:

- Material grade (S2, CRV, or stainless steel)

- Bit tip types (Phillips, Torx, Flat, Pozidriv, Security)

- Coating finishes (black oxide, nickel, titanium nitride)

- Branding options (laser logo, custom packaging, color-coded holders)

Cross-reference customization claims with actual listing diversity—suppliers with extensive tool portfolios (e.g., 1900+ screwdriver listings) typically possess scalable production infrastructure. Minimum order quantities vary significantly: from 2 sets for retail-ready kits to 500–1000 sets for bulk industrial orders, reflecting tiered pricing strategies optimized for different buyer segments.

Transaction Reliability & Responsiveness

Leverage response time and reorder rate as proxies for service quality. All analyzed suppliers report response times ≤4 hours, with 80% achieving ≤2 hours—critical for resolving technical queries or order adjustments. Reorder rates between 15–22% suggest moderate customer retention, indicating room for differentiation in after-sales support or product consistency. Online revenue exceeding US $400,000 at the top tier reflects proven export capability, particularly for multi-component sets (e.g., 117-in-1 or 258-piece configurations).

What Are the Best Screwdriver Bits Set Suppliers?

| Company Name | Main Products (Listings) | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Options | Sample MOQ | Key Product Range |

|---|---|---|---|---|---|---|---|---|

| Anhui Shengshi Hardware Tool Manufacturing Co., Ltd. | Screwdriver (1908), Drill Bits (249), Tool Sets (232) | US $240,000+ | 95% | 22% | ≤2h | Not specified | 2–100 sets | Multi-bit kits, socket tools, wrenches |

| Shenzhen Yiyun Technology Co., Ltd. | Tool Sets, Precision Screwdrivers | US $80,000+ | 100% | <15% | ≤2h | Color, size, logo, packaging | 2 sets | 117-in-1, 152-in-1 repair kits |

| Yiwu Jihan Hardware Tools Co., Ltd. | Screwdriver (46), Drill Bits (95), Tool Sets (32) | US $10,000+ | 100% | 15% | ≤2h | Customizable S2 bits | 100–500 sets | 31–38 piece sets, ratchet kits |

| Sichuan Machinery Tools & Imp. & Exp. Co., Ltd. | Drill Bits, Screwdriver Bits, Security Sets | US $420,000+ | 97% | 18% | ≤4h | Material, logo, packaging | 10–1000 pieces | 258-piece premium sets, magnetic PH2 |

| Hangzhou Juxincai Import And Export Co., Ltd. | Screwdriver (101), Power Screw Drivers, Tape Measures | US $20,000+ | 100% | <15% | ≤2h | Not specified | 2–10 sets | 128–150 in-1 multifunctional kits |

Performance Analysis

Sichuan Machinery Tools leads in sales volume (US $420,000+) and offers broad customization, making it suitable for branded private-label procurement. Anhui Shengshi stands out with the highest reorder rate (22%) and extensive product catalog, signaling strong market acceptance. Shenzhen Yiyun and Hangzhou Juxincai provide low MOQs (as low as 2 sets), ideal for e-commerce resellers or niche repair markets. Yiwu Jihan, despite lower revenue, maintains 100% on-time delivery and focuses on standardized industrial sets with scalable MOQs. Buyers seeking premium multi-tool kits should prioritize suppliers offering 100+ component sets with documented material specifications and protective case designs.

FAQs

How to verify screwdriver bits set supplier reliability?

Evaluate on-time delivery history (target ≥95%), response time (≤2 hours preferred), and reorder rate (≥15% indicates satisfaction). Request material certifications for S2 or CRV steel and inquire about hardness testing procedures. Review product images for consistency in finish and tip geometry—key indicators of quality control.

What is the typical lead time for screwdriver bits set orders?

Standard orders are fulfilled within 15–25 days after confirmation. Sample lead times range from 7–14 days depending on customization level. Expedited production may be available for stock configurations.

Can suppliers provide custom packaging and branding?

Yes, multiple suppliers explicitly offer logo printing, custom colors, and tailored packaging. Minimum thresholds typically start at 500 units for full branding, though some accept smaller runs (100–300 units) with surcharges.

What are common MOQs for screwdriver bits sets?

MOQs vary by supplier and product type: 2–10 sets for retail kits, 100–500 sets for wholesale industrial orders, and up to 1,000 pieces for individual bit components. Low-MOQ suppliers cater to startups and online sellers.

How to assess bit durability and compatibility?

Confirm use of S2 or CRV steel with heat-treated tips. Request torque test data or sample sets for field evaluation. Ensure shank type (hex, 1/4") matches end-user driver tools. For electronic repair, verify precision tip tolerances and magnetic strength.