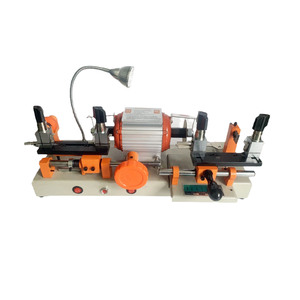

Self Key Maker

Top sponsor listing

Top sponsor listing

1/12

1/12

1/28

1/28

1/14

1/14

1/24

1/24

1/21

1/21

1/7

1/7

1/14

1/14

1/4

1/4

About self key maker

Where to Find Self Key Maker Suppliers?

China remains the global epicenter for self key maker manufacturing, with leading suppliers concentrated in Guangdong and Henan provinces. Shenzhen and Guangzhou serve as innovation hubs for automated key cutting systems, leveraging proximity to electronics and precision machinery supply chains. These regions support rapid prototyping and integration of embedded software for immobilizer key programming and RFID cloning functionalities. Meanwhile, Henan-based manufacturers focus on cost-efficient production of mechanical key cutters, benefiting from regional metalworking expertise and lower labor costs.

The industrial ecosystem enables vertically integrated operations—spanning CNC machining, circuit board assembly, and enclosure fabrication—within compact geographic zones. This integration reduces component lead times by 20–30% compared to fragmented international supply networks. Buyers gain access to scalable production capacity, with top-tier facilities capable of monthly outputs exceeding 1,000 units. The clustering effect also supports agile customization, including label graphics, activation card configurations, and OEM branding, typically within 15–25 days for sample validation.

How to Choose Self Key Maker Suppliers?

Procurement decisions should be guided by rigorous supplier evaluation criteria:

Technical Capability Verification

Confirm suppliers offer machines compatible with modern vehicle immobilizer systems and can program transponder keys (e.g., 125kHz, 80-bit encryption). Demand documentation for firmware update protocols and compatibility databases covering major automotive brands. For vending-style units, assess touchscreen interface responsiveness, payment system integration (coin, card, QR), and remote monitoring capabilities via cloud platforms.

Production Infrastructure Assessment

Evaluate operational scale through verifiable metrics:

- Facility size supporting dedicated R&D and testing zones

- In-house CNC and laser cutting equipment for precision tooling

- Integration of quality control checkpoints for motor calibration and blade alignment

Cross-reference online revenue indicators and on-time delivery rates (target ≥97%) to validate operational stability.

Transaction Security & Quality Assurance

Prioritize suppliers with documented quality management practices and participation in trade assurance programs. Require pre-shipment inspection rights and functional testing of sample units under real-world conditions. Analyze reorder rates—those below 15% may indicate limited customer retention or post-sale support gaps. Response times under 5 hours suggest strong service infrastructure, critical for technical troubleshooting and order tracking.

What Are the Best Self Key Maker Suppliers?

| Company Name | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|

| Shenzhen Lenkor Technology Development Co., Ltd. | Diagnostic Tools, Car Key Programmer, TPMS | 91% | ≤7h | <15% | US $690,000+ | Color, packaging, logo, key cloning, size, material |

| Shenzhen Hua Shi Locksmith Technology Co. Ltd. | Locksmith Supplies, Blank Keys, Diagnostic Tools | 97% | ≤5h | <15% | US $90,000+ | Limited customization reported |

| Chengdu Daobo Technology Co., Ltd. | Diagnostic Tools, Car Locksmith Tools, Vehicle Keys | 97% | ≤5h | 22% | US $240,000+ | Firmware-level support implied |

| GED (Guangzhou) Import And Export Limited | Button Making Machines, Heat Press, Plotter | 100% | ≤7h | <15% | US $70,000+ | Basic shape and size options |

| Henan Jinfuda Trading Co., Ltd. | Key Cutting Machines, Custom Branding | 98% | ≤3h | <15% | US $570,000+ | Color, material, logo, packaging, label, graphic |

Performance Analysis

Shenzhen-based suppliers demonstrate strong specialization in diagnostic-integrated key programmers, with Lenkor offering extensive customization across labeling, configuration, and cloning features. Hua Shi Locksmith and Chengdu Daobo achieve high on-time delivery (97%) and fast response times, indicating robust operational discipline. GED stands out with a perfect 100% on-time delivery record, though its core competencies lie outside locksmithing, potentially limiting technical depth. Henan Jinfuda leads in responsiveness (≤3h) and offers broad customization, supported by substantial transaction volume. A 22% reorder rate at Chengdu Daobo suggests stronger post-sale satisfaction relative to peers, despite lower online revenue visibility.

FAQs

How to verify self key maker supplier reliability?

Cross-check delivery performance and response metrics with third-party platform data. Request evidence of compliance with CE or FCC standards where applicable. Validate technical claims through live demos or video audits of machine operation, focusing on cutting accuracy and programming success rates across multiple key types.

What is the typical sampling timeline for self key makers?

Standard models require 7–14 days for sample production. Units with custom firmware, branding, or payment integration may take 20–30 days. Air freight adds 5–10 days for international delivery. Budget an additional week for import clearance in regulated markets.

Do suppliers support global shipping and customs compliance?

Yes, most established suppliers manage FOB and CIF shipments worldwide. Confirm inclusion of export documentation, voltage compatibility (110V/220V), and adherence to destination-country electrical safety standards. Pre-shipment inspections are recommended to mitigate logistics risks.

Are free samples available for self key making machines?

Free samples are rare due to high unit value. Suppliers typically charge full or partial fees, refundable against bulk orders (e.g., minimum 3–5 units). Sample costs range from $1,500 to $9,500 depending on automation level and programming features.

What customization options are commonly offered?

Suppliers provide configurability in housing color, user interface language, logo printing, packaging design, and key blank compatibility. Advanced vendors support API integration for cloud-based machine monitoring, remote diagnostics, and sales reporting. Confirm software update policies and technical support availability before finalizing contracts.