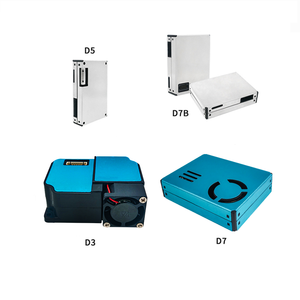

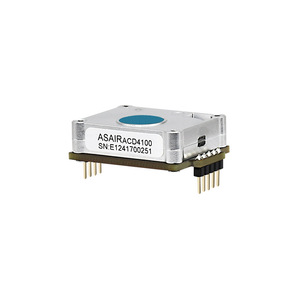

Sensor Module Producer

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/1

1/1

1/3

1/3

1/2

1/2

1/3

1/3

1/2

1/2

1/3

1/3

1/3

1/3

0

0

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

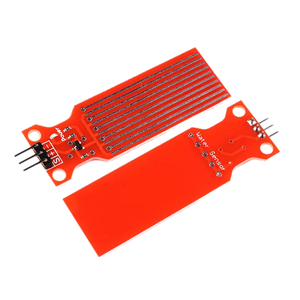

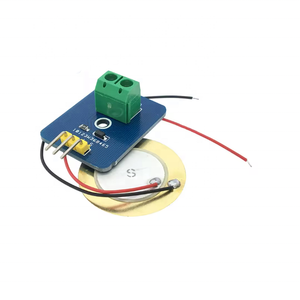

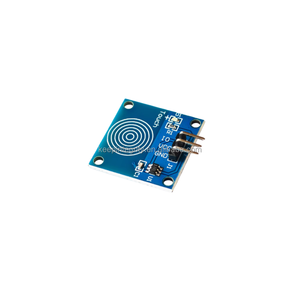

About sensor module producer

Where to Find Sensor Module Producer Suppliers?

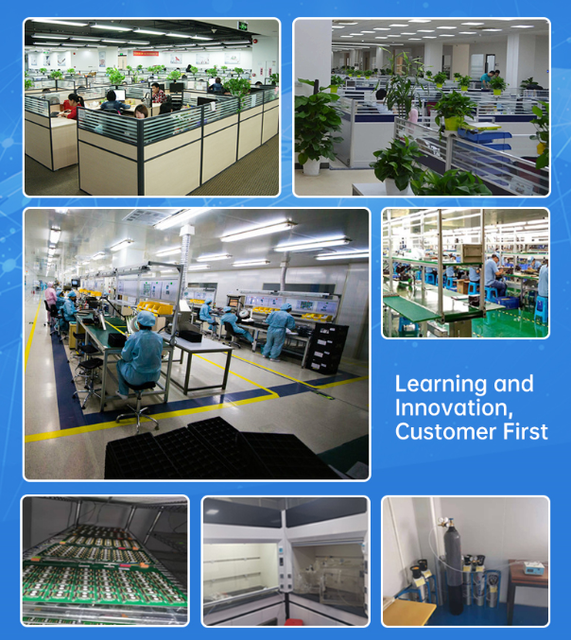

China remains the central hub for sensor module production, with advanced manufacturing ecosystems concentrated in Guangdong, Jiangsu, and Zhejiang provinces. These regions host over 70% of China’s electronics component suppliers, supported by dense networks of semiconductor foundries, PCB fabricators, and SMT assembly lines. Shenzhen, in particular, offers rapid prototyping capabilities and access to Tier-1 material suppliers, enabling faster iteration cycles for IoT, industrial automation, and smart device applications.

The clusters support high levels of vertical integration, with many producers managing full workflows—from bare die packaging to final calibration—within single facilities. This integration reduces component sourcing lead times by 25–40% compared to fragmented supply chains. Buyers benefit from scalable production models capable of fulfilling low-volume custom batches (under 1,000 units/month) to high-volume OEM runs exceeding 500,000 units/month. Average delivery timelines range from 20–35 days, depending on complexity and testing requirements.

How to Choose Sensor Module Producer Suppliers?

Implement structured evaluation criteria to ensure technical and operational reliability:

Quality Management Standards

Confirm ISO 9001 certification as a baseline for process control. For regulated sectors (medical, automotive, industrial safety), require IATF 16949, ISO 13485, or equivalent certifications. Verify compliance with RoHS, REACH, and halogen-free standards where environmental regulations apply. Request test reports for EMI/EMC, thermal stability, and long-term drift performance.

Production Infrastructure Assessment

Evaluate key operational metrics:

- Minimum 2,000m² cleanroom-equipped facility for precision assembly

- In-house SMT lines with placement accuracy ≤±0.025mm for fine-pitch ICs

- Dedicated calibration and environmental testing chambers (temperature, humidity, vibration)

Cross-check monthly output capacity against order volume needs. Suppliers handling >100,000 units/month should demonstrate automated optical inspection (AOI) and traceability systems (e.g., barcode/RFID per unit).

Technical and Transaction Safeguards

Require sample validation under real-world operating conditions before mass production. Use third-party inspection services (e.g., SGS, TÜV) for AQL 2.5/4.0 checks during final shipment audits. Prioritize suppliers offering firmware documentation, SDKs, and pin-compatible alternatives for future design scalability. Escrow payment terms are recommended until post-arrival functional verification is completed.

What Are the Best Sensor Module Producer Suppliers?

No supplier data available for comparative analysis.

Performance Considerations

In absence of specific supplier profiles, buyers should focus on identifying manufacturers with documented experience in target application fields—such as environmental sensing, motion detection, or gas monitoring. Proven track records in export markets (especially EU and North America) indicate familiarity with regulatory documentation and packaging standards. Emphasis should be placed on responsiveness (<4-hour average reply time), availability of technical datasheets, and willingness to provide reference designs or integration support.

FAQs

How to verify sensor module producer credibility?

Audit quality certifications through official databases and request factory audit reports from prior clients. Validate export history via bill of lading records or customs data platforms. Assess technical competence by requesting detailed failure mode analyses (FMEA) and MTBF (Mean Time Between Failures) data.

What is the typical sampling timeline for sensor modules?

Standard samples take 7–14 days to produce, including programming and basic calibration. Customized versions with modified sensing elements or communication protocols (e.g., Modbus, I2C, LoRaWAN) may require 20–30 days. Air shipping adds 5–9 days internationally.

Do sensor module producers support global shipping?

Yes, most established manufacturers offer EXW, FOB, and CIF shipping terms. They coordinate export documentation, including commercial invoices, packing lists, and certificates of origin. Compliance with destination-specific labeling (e.g., CE marking, FCC ID) must be confirmed prior to dispatch.

Are free samples available from sensor module suppliers?

Sample policies vary. Many suppliers waive fees for qualified buyers committing to minimum orders (typically ≥500 units). Otherwise, expect to pay 50–100% of unit cost, which may be credited toward first production run.

How to initiate customization projects with sensor module producers?

Submit detailed specifications: sensing type (temperature, pressure, PIR, etc.), output signal (analog/digital), power requirements (voltage, current draw), enclosure IP rating, and communication interface. Leading producers respond with schematic proposals, layout suggestions, and 3D mechanical drawings within 5–7 business days.