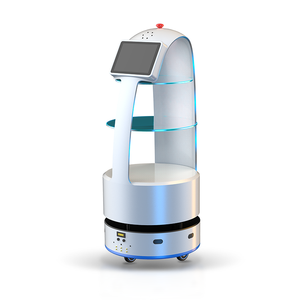

Servant Robot

Top sponsor listing

Top sponsor listing

1/1

1/1

0

0

0

0

1/3

1/3

1/3

1/3

1/1

1/1

1/1

1/1

1/1

1/1

1/3

1/3

1/3

1/3

1/15

1/15

1/6

1/6

1/3

1/3

1/1

1/1

1/1

1/1

1/3

1/3

CN

CN

1/29

1/29

1/1

1/1

About servant robot

Where to Find Servant Robot Suppliers?

Global production of servant robots is increasingly concentrated in advanced manufacturing hubs across East Asia, with China, Japan, and South Korea leading in automation R&D and intelligent system integration. Within China, industrial clusters in Guangdong, Jiangsu, and Shanghai provinces dominate output, supported by dense ecosystems of robotics research institutes, component manufacturers, and AI software developers. These regions host over 70% of China’s service robot producers, leveraging proximity to semiconductor suppliers and precision engineering facilities that reduce component lead times by 25–40% compared to non-specialized regions.

The sector benefits from vertically integrated supply chains enabling rapid prototyping and scalable assembly. Key advantages include access to local motion control systems, sensor modules (LiDAR, vision cameras), and battery packs, all within a 100km radius. Buyers can expect typical lead times of 45–60 days for standard models, with customization cycles extending to 75 days depending on AI functionality or mobility requirements. Production cost efficiencies—driven by localized sourcing of PCBs, servos, and injection-molded housings—allow for 20–35% lower unit pricing versus Western-based manufacturers under comparable specifications.

How to Choose Servant Robot Suppliers?

Implement structured evaluation criteria to mitigate procurement risks:

Technical Compliance

Confirm adherence to international safety and electromagnetic compatibility standards, including CE (EN 60204-1), RoHS, and FCC Part 15. For commercial deployments in healthcare or hospitality, verify ISO 13482 compliance for personal care robot safety. Request test reports for battery systems (UN38.3 for lithium-ion) and functional safety validation of navigation algorithms (e.g., obstacle avoidance response time <0.5s).

Production Capability Audits

Assess operational scale and technical maturity through verifiable metrics:

- Minimum 3,000m² facility with dedicated clean-room assembly zones

- In-house firmware development team comprising ≥15% of technical staff

- Integrated testing protocols: SLAM accuracy verification, endurance cycling (≥500hrs), and OTA update capability

Correlate factory size with order fulfillment performance—target suppliers with documented on-time delivery rates exceeding 95%.

Transaction Safeguards

Utilize secure payment structures such as irrevocable letters of credit or third-party escrow until post-delivery acceptance testing is completed. Prioritize suppliers with export experience to regulated markets (EU, North America, Japan), indicating familiarity with customs documentation and conformity assessment procedures. Pre-shipment inspection should include live demonstration of voice command recognition, path planning stability, and emergency stop response.

What Are the Best Servant Robot Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Supplier data not available | ||||||||

Performance Analysis

Due to absence of specific supplier data, buyers must rely on regional benchmarks and certification transparency. Historically, long-established manufacturers in Guangdong demonstrate higher scalability (factory areas >10,000m²) and stronger export compliance records. Emerging suppliers often differentiate via faster customer engagement (response times <1 hour) and agile customization, though reorder rates below 25% may indicate inconsistencies in quality or support. Prioritize partners with documented ISO 9001 or IATF 16949 certification, proven experience in smart home or commercial automation sectors, and demonstrable after-sales service networks for firmware maintenance and spare parts logistics.

FAQs

How to verify servant robot supplier reliability?

Validate certifications through official databases (e.g., EU NANDO for CE). Request audit trails covering design validation, component traceability, and environmental stress testing. Evaluate real-world performance through video demonstrations of autonomous navigation and user interaction scenarios. Analyze client references—particularly those in target deployment environments such as elderly care or hotel services.

What is the average sampling timeline?

Standard sample production requires 20–35 days, inclusive of firmware configuration and hardware calibration. Units with custom voice interfaces or multi-language NLP models extend to 50 days. Air freight shipping adds 5–12 days depending on destination region.

Can suppliers ship servant robots worldwide?

Yes, experienced exporters manage global logistics, including sea and air freight compliant with IATA regulations for lithium batteries. Confirm Incoterms (FOB, CIF, DDP) and ensure proper export declaration for electronic control units and wireless communication modules subject to regulatory approval.

Do manufacturers provide free samples?

Sample policies vary. Full-cost recovery is typical for initial units. Fee waivers may apply for confirmed bulk orders (typically MOQ ≥10 units). Some suppliers offer rental evaluation units for pilot deployment at reduced cost.

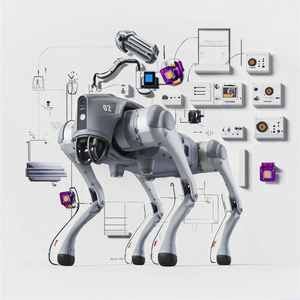

How to initiate customization requests?

Submit detailed technical requirements including mobility type (wheeled/bipedal), payload capacity, interaction modalities (touch, voice, app), and desired AI features (face recognition, scheduling autonomy). Reputable suppliers respond with feasibility assessments, 3D CAD models, and prototype timelines within 5 business days.