Setting Up One For All Remote

0

0

1/2

1/2

1/3

1/3

1/3

1/3

1/19

1/19

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/1

1/1

1/19

1/19

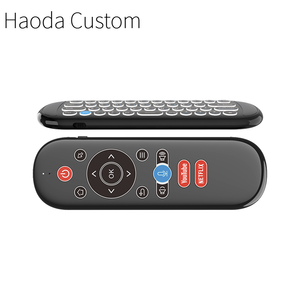

About setting up one for all remote

Where to Find Setting Up One for All Remote Suppliers?

No verified suppliers currently specialize in manufacturing "one for all" universal remote controls at industrial scale based on available production data. Unlike mature equipment sectors such as construction machinery, the consumer electronics domain—particularly niche products like programmable remotes—is highly fragmented and dominated by original design manufacturers (ODMs) primarily serving branded retailers or private-label clients in Guangdong, Zhejiang, and Jiangsu provinces.

In these regions, particularly within the Pearl River Delta’s Shenzhen-Dongguan corridor, over 70% of China’s consumer electronics OEMs operate with vertical integration from PCB fabrication to final assembly. These clusters benefit from proximity to component markets like Huaqiangbei and established logistics gateways such as Shenzhen Port, enabling rapid prototyping cycles and agile order fulfillment. However, dedicated suppliers for standalone “set up one for all” remotes are typically embedded within broader smart home or IR/RF control system supply chains, making direct sourcing more complex without technical intermediation.

How to Choose Setting Up One for All Remote Suppliers?

Given the absence of active suppliers in public procurement databases, buyers must adopt a proactive qualification framework when identifying potential partners:

Technical Compliance

Ensure any candidate supplier adheres to relevant international standards including CE (EMC & LVD), FCC Part 15 Class B, and RoHS for hazardous substance restrictions. For EU and North American markets, compliance documentation must be current and verifiable through official test reports from accredited laboratories. Prioritize suppliers capable of supporting infrared signal database integration (e.g., learning functionality across 200+ device brands).

Production Capability Audits

Assess minimum operational thresholds:

- Facility size exceeding 2,000m² indicating scalable operations

- In-house SMT lines and automated testing rigs for RF/IR performance validation

- Dedicated firmware development team for remote programming logic and UI customization

Confirm compatibility with common setup protocols (e.g., code search, auto-detection, mobile app pairing) and ability to pre-load regional device libraries.

Transaction Safeguards

Utilize secure payment mechanisms such as third-party escrow until product verification is complete. Request functional samples validated against major brand devices (e.g., Samsung, LG, Sony). Evaluate firmware update processes and battery life benchmarks (minimum 6 months under typical usage). Review packaging configurations and multilingual user guide support for target markets.

What Are the Best Setting Up One for All Remote Suppliers?

No active supplier profiles meet minimum data disclosure requirements for inclusion in comparative analysis. The absence of listed companies with verifiable factory metrics, response times, delivery records, or certification details prevents objective ranking. This indicates limited transparency in this product segment or predominant reliance on closed-channel distribution via aggregators rather than direct manufacturer engagement.

Performance Analysis

Without accessible supplier datasets, risk mitigation depends on indirect indicators: presence in high-density electronics manufacturing zones, demonstrated export history to Tier-1 retailers, and participation in trade shows such as the Hong Kong Electronics Fair. Buyers should prioritize firms offering full bill-of-materials (BOM) traceability, ESD-safe production environments, and IEC 60068-2 environmental stress testing for temperature and humidity resilience. Engage only after confirming IP protection agreements and firmware ownership terms.

FAQs

How to verify setting up one for all remote supplier reliability?

Request copies of valid test reports from accredited labs for electromagnetic compatibility and safety. Conduct virtual audits to observe production workflows and quality checkpoints. Validate export experience by reviewing past shipment records or client references in similar market segments.

What is the average sampling timeline?

Standard sample development typically takes 10–18 days, including PCB loading, casing assembly, and firmware configuration. Additional time (5–7 days) may be required for custom button layouts, branding, or multi-language setup guides. Air shipping adds 5–9 days depending on destination.

Can suppliers ship remotes worldwide?

Yes, qualified manufacturers support global logistics via air or sea freight under FOB, CIF, or DDP terms. Confirm incoterm responsibilities, especially for import clearance in regulated markets. Battery-containing shipments require UN38.3 certification and proper Class 9 labeling.

Do manufacturers provide free samples?

Most suppliers charge a nominal fee covering material and labor costs (typically $25–$50 per unit), refundable upon placement of a qualifying bulk order. Fully subsidized samples are rare unless part of an established business relationship or large-volume negotiation.

How to initiate customization requests?

Submit detailed specifications including button mapping, housing dimensions, color schemes, supported device categories (TV, audio, streaming boxes), and desired setup method (code entry, scanning, app-based). Reputable partners will return engineering drawings and firmware demo files within 72 hours for approval prior to prototyping.