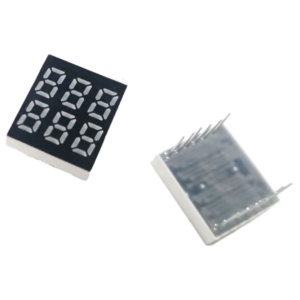

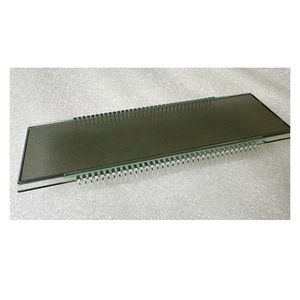

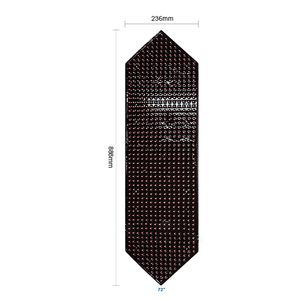

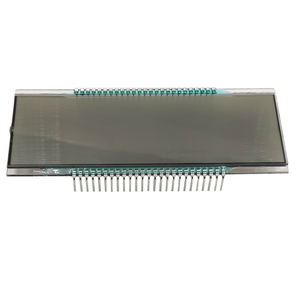

Seven Segment Display

Top sponsor listing

Top sponsor listing

0

0

1/3

1/3

1/37

1/37

1/27

1/27

1/23

1/23

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/29

1/29

1/20

1/20

About seven segment display

Where to Find Seven Segment Display Suppliers?

China remains the central hub for seven segment display manufacturing, with concentrated production clusters in Guangdong and Jiangsu provinces. These regions host over 70% of global LED display component suppliers, supported by mature electronics supply chains and specialized industrial parks focused on optoelectronics and PCB assembly. Dongguan and Shenzhen in Guangdong province offer rapid prototyping and high-volume SMT production, while Jiangsu’s Suzhou and Wuxi zones emphasize precision engineering and automated testing for enhanced product consistency.

The ecosystem enables vertically integrated manufacturing—from epoxy molding and die bonding to final burn-in testing—within compact geographic zones. This integration reduces component transit time and supports just-in-time delivery models. Buyers benefit from shorter lead times (typically 15–25 days for standard configurations), 25–35% lower unit costs compared to Western or Southeast Asian alternatives, and access to flexible MOQs ranging from 100 to 5,000 units. The proximity of material suppliers (e.g., GaAs wafers, phosphor coatings, lead frames) and contract assembly services allows for agile customization and faster iteration cycles.

How to Choose Seven Segment Display Suppliers?

Implement structured evaluation criteria to ensure technical and operational reliability:

Quality & Compliance Verification

Confirm adherence to international standards including ISO 9001 for quality management and IEC 61000-4 for electromagnetic compatibility. For export to EU and North American markets, RoHS and REACH compliance is mandatory. Request test reports for luminance uniformity (measured in mcd), forward voltage tolerance (±0.1V), and operating temperature range (-30°C to +85°C). Verify that displays undergo 48-hour burn-in testing and thermal cycling to screen for early failure modes.

Production Capability Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum 2,000m² cleanroom facility with ESD protection

- SMT lines capable of 0201 component placement accuracy

- In-house mold tooling and injection capabilities for custom digit shapes

Cross-check monthly output capacity (target: ≥500,000 units) against historical order fulfillment data to assess scalability.

Procurement Risk Mitigation

Utilize third-party inspection services (e.g., SGS, TÜV) for pre-shipment audits, particularly for first-time orders. Prioritize suppliers offering sample validation under real operating conditions—benchmark brightness, viewing angle (>120°), and current draw against datasheet specifications. Secure payment terms via escrow until product conformity is confirmed. Analyze supplier responsiveness (target: ≤4 hours) and technical support depth when evaluating long-term partnership potential.

What Are the Best Seven Segment Display Suppliers?

No verified supplier data available at this time.

Performance Analysis

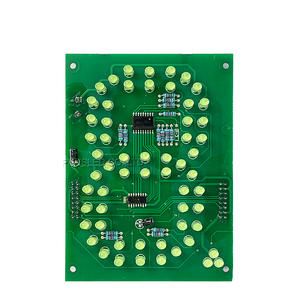

In absence of specific supplier profiles, procurement focus should remain on regional advantages and capability thresholds. Guangdong-based manufacturers typically excel in fast-turn assembly and small-form factor designs due to dense SMT infrastructure. Jiangsu suppliers often provide superior optical clarity and color consistency through controlled encapsulation processes. Prioritize facilities with documented traceability systems, automated optical inspection (AOI), and UL-certified materials for safety-critical applications. For custom variants—such as high-brightness white, dual-color, or surface-mount 4-digit modules—confirm design-for-manufacturability (DFM) review availability and NRE cost transparency before tooling commitment.

FAQs

How to verify seven segment display supplier reliability?

Audit quality documentation including process flowcharts, control plans, and first-article inspection (FAI) reports. Validate certifications through official databases and request references from existing clients in similar industries (e.g., industrial controls, consumer appliances). On-site or virtual factory audits are recommended to assess equipment calibration and workforce training protocols.

What is the average sampling timeline?

Standard samples take 7–10 days for ready-made models. Custom designs requiring new molds or PCB layouts require 18–25 days, including tooling setup and initial run testing. Air shipping adds 5–7 days for international delivery.

Can suppliers ship seven segment displays worldwide?

Yes, most established manufacturers support global logistics via air or sea freight under FOB, CIF, or DDP terms. Ensure packaging meets ISTA 3A standards for electronic goods and confirm export compliance with destination regulations, especially for battery-powered or IoT-integrated displays.

Do manufacturers provide free samples?

Sample policies vary. Many suppliers offer 1–3 free units for qualified buyers committing to MOQ fulfillment. For complex or large-format displays, expect nominal fees covering 20–40% of unit cost, refundable upon order placement.

How to initiate customization requests?

Submit detailed technical requirements including digit height (e.g., 0.28", 0.56"), common anode/cathode configuration, pin layout, and desired color (red, green, yellow, blue). Reputable partners will return dimensioned drawings, material specifications, and prototype timelines within 5 business days.