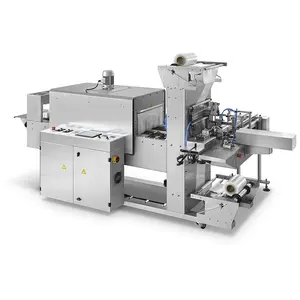

Shrink Wrapping Machine For Pet Bottles

Top sponsor listing

Top sponsor listing

1/12

1/12

1/21

1/21

1/12

1/12

1/15

1/15

1/3

1/3

1/13

1/13

1/16

1/16

About shrink wrapping machine for pet bottles

Where to Find Shrink Wrapping Machine Suppliers for PET Bottles?

China remains the dominant hub for manufacturing shrink wrapping machines tailored for PET bottles, with key production clusters concentrated in Jiangsu, Guangdong, and Henan provinces. These regions host vertically integrated supply chains that support rapid prototyping and scalable production. Zhangjiagang in Jiangsu, for example, is renowned for its packaging machinery ecosystem, where specialized manufacturers benefit from proximity to raw material suppliers and export logistics networks. Dongguan in Guangdong offers advanced automation expertise, particularly in compact and semi-automatic models suited for mid-volume bottling lines.

The industrial advantage lies in localized access to precision components, film extrusion facilities, and thermal control systems, enabling cost efficiencies of 20–35% compared to Western or Southeast Asian alternatives. Facilities typically integrate design, fabrication, assembly, and testing under one roof, reducing lead times to 30–45 days for standard configurations. Buyers gain flexibility in both volume procurement and custom engineering, supported by a mature network of OEMs and ODMs capable of handling technical modifications for sleeve type, conveyor integration, and heat distribution systems.

How to Choose Shrink Wrapping Machine Suppliers for PET Bottles?

Selecting reliable suppliers requires rigorous evaluation across three critical dimensions:

Technical and Operational Compliance

Confirm adherence to international safety and performance benchmarks. While ISO 9001 certification is commonly cited among leading manufacturers, buyers should explicitly request CE marking for compliance with European electrical and mechanical standards. Verify documentation for heating element durability, temperature control accuracy (±2°C), and energy efficiency metrics. Machines designed for high-speed bottling lines (>6,000 bottles/hour) must demonstrate stable film sealing performance under continuous operation.

Production and Customization Capacity

Assess supplier capabilities through verifiable indicators:

- Minimum factory area exceeding 3,000m² to ensure dedicated production zones

- In-house engineering teams supporting customization of tunnel dimensions, conveyor widths, voltage specifications (110V/220V/380V), and PLC controls

- Proven experience modifying machines for specific bottle geometries (round, oval, multi-neck) and shrink film types (PVC, PE, PETG)

Cross-reference product listings with on-time delivery rates above 90% and response times under 3 hours as proxies for operational reliability.

Transaction and Quality Assurance

Prioritize suppliers offering third-party inspection options prior to shipment. Utilize documented quality control checkpoints—such as pre-shipment testing videos or factory audit reports—to validate machine functionality. Request sample units for performance benchmarking, particularly for seal consistency, film waste ratio, and recovery time after power fluctuations. Analyze reorder rates: values exceeding 40% indicate strong customer retention and post-sale satisfaction.

What Are the Best Shrink Wrapping Machine Suppliers for PET Bottles?

| Company Name | Main Products | Customization Options | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Product Range |

|---|---|---|---|---|---|---|---|

| Zhangjiagang Paima Packaging Machinery Co., Ltd. | Labeling, Filling, Wrapping, Preforms, Stretch Blow Moulding | Color, material size, logo, packaging label, graphic | 87% | 40% | ≤3h | US $210,000+ | 15+ models |

| Dongguan Sammi Packing Machine Co., Ltd. | Shrink tunnels, sleeve wrappers, semi-automatic systems | Bag size, material, weight, model, height, bag type | 88% | <15% | ≤2h | US $380,000+ | 5 models |

| Zhangjiagang Maicheng Packaging Machinery Co., Ltd. | Filling, Wrapping, Labeling, Water Treatment | Limited public data | 100% | - | ≤4h | - | 4 models |

| Henan Tianzhong Machinery Co., Ltd. | Wrapping, Multi-function Packaging, Labeling | Neck covering, 2-in-1 configurations, steam/heat variants | 100% | <15% | ≤2h | US $130,000+ | 5 models |

| Ruian Huadong Packing Machinery Co., Ltd. | Full-automatic shrink wrappers, sleeve sealers | Color, material, logo, packaging design | 100% | 50% | ≤1h | US $240,000+ | 5 models |

Performance Analysis

Ruian Huadong stands out with a 50% reorder rate and sub-hour response time, indicating robust customer trust and service responsiveness. Zhangjiagang Paima combines broad product diversity with a high reorder rate, suggesting consistent performance across labeling, filling, and wrapping integrations. Notably, three suppliers—Maicheng, Tianzhong, and Huadong—report 100% on-time delivery, reflecting disciplined production scheduling despite varying company sizes. However, low reorder rates (<15%) at Sammi and Tianzhong may signal gaps in after-sales support or long-term reliability despite timely fulfillment. Buyers seeking full automation should prioritize suppliers offering end-to-end line integration, while those needing entry-level systems can leverage competitively priced desktop or semi-automatic models starting at $280.

FAQs

What certifications should shrink wrapping machine suppliers have?

Essential certifications include ISO 9001 for quality management and CE for compliance with EU safety, health, and environmental standards. For U.S. and Canadian markets, UL or CSA verification may be required for electrical components. Always request certified test reports for insulation resistance, grounding continuity, and overheat protection.

What is the typical MOQ and lead time?

Most suppliers offer a minimum order quantity (MOQ) of 1 set, facilitating sample testing and small-scale deployment. Lead times range from 15 days for standard models to 30–45 days for customized or fully automatic systems. Expedited production may be available at a premium.

Can shrink wrapping machines be customized for specific bottle sizes?

Yes, reputable suppliers provide customization for bottle diameter (25–100mm), height (80–350mm), and arrangement patterns (single or multi-lane). Modifications include adjustable side sealer jaws, variable-frequency drives (VFD) for speed control, and modular tunnel designs to accommodate different shrink sleeve lengths.

Do suppliers offer installation and technical support?

Support varies by manufacturer. Leading suppliers provide remote guidance via video, user manuals in English, and troubleshooting protocols. Some offer on-site commissioning services at additional cost. Confirm availability of spare parts inventory and firmware updates before purchase.

What are the common power and film requirements?

Standard machines operate on 220V/50Hz or 380V/50Hz three-phase power. Low-capacity desktop models may run on 110V. Compatible films include PE (polyethylene), PVC, and PETG, with thicknesses ranging from 30–75μm. Ensure compatibility between film shrinkage ratio (typically 40–70%) and machine temperature profile.