Silicon Dioxide Sio2

1/3

1/3

CN

CN

1/6

1/6

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

About silicon dioxide sio2

Where to Find Silicon Dioxide (SiO2) Suppliers?

China maintains a dominant position in the global silicon dioxide (SiO2) supply chain, with key production clusters in Jiangsu, Shandong, and Guangdong provinces. These regions host vertically integrated facilities specializing in nano-silica, fumed silica, precipitated silica, and high-purity quartz powders. Jiangsu and Shandong are particularly notable for advanced nanomaterial processing capabilities, supported by localized R&D centers and chemical engineering expertise. The concentration of raw material suppliers, packaging manufacturers, and logistics networks within 50km radii enables efficient production cycles and cost optimization.

Suppliers in these industrial hubs benefit from economies of scale, achieving production capacities ranging from several hundred kilograms to multiple tons per month. Many operate under cleanroom environments for nano-SiO2 synthesis, utilizing sol-gel, flame hydrolysis, or precipitation methods. This infrastructure supports rapid fulfillment of both standard and customized orders, with typical lead times between 7–15 days for in-stock items. Buyers gain access to diverse product forms—including powders, dispersions, and surface-modified variants—across purity levels (98%–99.99%) and particle sizes (1–400 nm).

How to Choose Silicon Dioxide (SiO2) Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Quality Management Systems

Prioritize suppliers with documented quality control protocols. While formal ISO 9001 certification is not universally listed, consistent on-time delivery rates above 97% and verifiable test reports (e.g., BET surface area, XRD analysis, CAS number verification) serve as proxies for process reliability. For applications in pharmaceuticals, electronics, or food-grade materials, request compliance documentation for RoHS, REACH, or FDA standards.

Production & Customization Capability

Assess technical flexibility through available customization options:

- Surface treatment (e.g., KH550, KH570 silane coupling agents)

- Powder dispersion stability and liquid formulation options

- Packaging configuration (bulk bags, sealed containers, labeled units)

- Particle size control (20nm, D50 200–400 mesh spherical SiO2)

Cross-reference product listings with minimum order quantities (MOQs) and pricing tiers to confirm scalability. Suppliers offering multi-kilogram samples and batch-specific certificates of analysis (CoA) demonstrate stronger quality accountability.

Transaction Reliability Indicators

Analyze performance metrics where available:

- On-time delivery rate ≥97%

- Average response time ≤4 hours

- Reorder rate >15% indicating customer retention

- Online transaction volume exceeding US $200,000 annually

Shorter response times and higher reorder rates correlate with operational responsiveness and service consistency. Escrow-based payment terms and sample testing prior to bulk procurement mitigate financial and quality risks.

What Are the Best Silicon Dioxide (SiO2) Suppliers?

| Company Name | Location | Main Products | Min. Order Quantity | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Annual Revenue (Est.) |

|---|---|---|---|---|---|---|---|---|

| Jiangsu Xfnano Materials Tech Co., Ltd. | Jiangsu, CN | Nano-SiO2, Surface-Modified Silica | 100 grams | $0.15–0.25/g | 87% | ≤8h | <15% | US $30,000+ |

| Shenzhen Qidian Chemical Industry Co., Ltd. | Guangdong, CN | Spherical SiO2, Fused Silica, Quartz Sand | 1,000 kg | $0.45–7.50/kg | 100% | ≤1h | 40% | US $900+ |

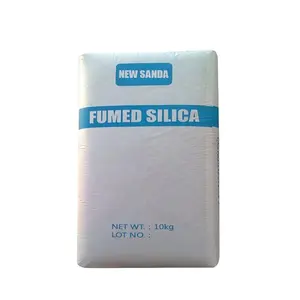

| Shandong Near Chemical Co., Ltd. | Shandong, CN | Fumed Silica, Precipitated Silica | 5,000 kg | $0.85–1.15/kg | 100% | ≤2h | <15% | US $860,000+ |

| Luoyang Tongrun Info Technology Co., Ltd. | Henan, CN | Nano-SiO2 Powder, Dispersions, Liquid SiO2 | 1–10 kg | $3.20–48/kg | 100% | ≤1h | 17% | US $260,000+ |

| Hebei Suoyi New Material Technology Co., Ltd. | Hebei, CN | Nano-Silica Powder, Oxide Ceramics | 1 kg | $4.90–49/kg | 100% | ≤4h | 16% | US $200,000+ |

Performance Analysis

Shenzhen Qidian and Shandong Near Chemical stand out for industrial-scale supply, offering competitive pricing and full compliance with large-volume MOQs. Shenzhen Qidian’s 100% on-time delivery and sub-hour response time reflect strong operational discipline, while its 40% reorder rate indicates high buyer satisfaction. Jiangsu Xfnano provides niche capability in ultrafine (20nm), high-purity nano-SiO2 with low entry MOQs (100g), suitable for R&D and pilot testing despite lower delivery performance. Luoyang Tongrun and Hebei Suoyi offer flexible sampling and mid-range pricing, ideal for specialty formulations requiring small-batch procurement. Shandong Near Chemical leads in export-ready capacity, backed by six-figure annual revenue and robust packaging customization.

FAQs

How to verify silicon dioxide supplier reliability?

Evaluate on-time delivery history, response time consistency, and transaction volume. Request batch-specific test reports including particle size distribution (PSD), specific surface area (m²/g), loss on ignition (LOI), and trace metal content. Confirm CAS numbers (e.g., 7631-86-9 for amorphous SiO2, 14808-60-7 for fumed silica) match product specifications.

What is the typical sampling timeline for SiO2 materials?

Standard samples ship within 3–7 days. Complex modifications (e.g., functionalized surfaces, aqueous dispersions) may require 10–14 days. Air freight delivery to international destinations averages 5–10 days.

Can suppliers provide custom-formulated silicon dioxide?

Yes, many suppliers offer surface modification (e.g., silanization), controlled agglomeration, and tailored dispersibility. Confirm availability of technical data sheets (TDS) and compatibility testing support before integration into end-use applications.

What are common MOQs for nano and industrial-grade SiO2?

Research-grade nano-SiO2 starts at 100g–1kg. Industrial fumed or precipitated silica typically requires 5,000kg minimum. Spherical and fused quartz products often have 1,000kg thresholds. Negotiation for lower volumes is possible with premium pricing.

How to assess packaging and storage conditions?

Demand moisture-resistant, sealed packaging for hygroscopic forms like fumed silica. Verify use of inert liners and nitrogen purging for long-term stability. Suppliers should specify shelf life and recommend storage below 25°C and 50% relative humidity.