Simple Projects With Wood

Top sponsor listing

Top sponsor listing

0

0

1/2

1/2

1/3

1/3

1/3

1/3

CN

CN

1/31

1/31

0

0

0

0

1/29

1/29

1/3

1/3

1/21

1/21

1/29

1/29

1/3

1/3

0

0

0

0

0

0

About simple projects with wood

Where to Find Suppliers for Simple Wood Projects?

China remains the leading global manufacturing hub for woodworking products, with concentrated supplier clusters in Zhejiang, Guangdong, and Fujian provinces. These regions host vertically integrated production ecosystems specializing in small-scale woodcraft items, leveraging local timber resources and decades of artisanal expertise combined with modern CNC processing. Zhejiang’s Jinhua and Hangzhou zones account for over 50% of China’s export-oriented wooden handicraft output, supported by efficient plywood, MDF, and solid wood supply chains that reduce raw material lead times by 20–30% compared to other markets.

These industrial clusters enable rapid prototyping and scalable production through access to automated cutting, sanding, and finishing lines. Facilities typically integrate design, laser engraving, and assembly under one roof, allowing for MOQs as low as 50 units with average lead times of 15–25 days for standard orders. Buyers benefit from localized component networks—wood suppliers, varnish manufacturers, and packaging providers—located within 30–50km radii, minimizing logistical complexity. Cost advantages are significant, with production expenses averaging 25–40% below those in North America and Europe due to lower labor costs and streamlined workflows.

How to Choose Suppliers for Simple Wood Projects?

Implement structured evaluation criteria when selecting manufacturing partners:

Quality Management Systems

Confirm ISO 9001 certification as a baseline indicator of consistent production controls. For exports to EU and US markets, verify compliance with FSC (Forest Stewardship Council) chain-of-custody standards and CARB P2 / EPA TSCA Title VI regulations for formaldehyde emissions in composite woods. Request test reports for finishes, particularly water-based or non-toxic coatings intended for children's toys or educational kits.

Production Capability Assessment

Evaluate operational scale and technical capacity:

- Minimum facility size of 1,000m² to support batch production

- In-house CNC routers, laser cutters, or carving machines for precision detailing

- Integrated sanding, staining, and sealing stations to ensure finish consistency

Cross-reference equipment lists with order fulfillment history; target suppliers maintaining on-time delivery rates above 95%.

Procurement Safeguards

Utilize secure payment mechanisms such as third-party escrow services until goods pass post-arrival inspection. Prioritize suppliers with documented quality control checkpoints at each stage—material intake, mid-production, and final packaging. Pre-shipment inspections should include grain alignment verification, dimensional accuracy checks, and coating adhesion testing. Sampling is strongly advised: request physical prototypes before committing to bulk orders to assess craftsmanship and material authenticity.

What Are the Best Suppliers for Simple Wood Projects?

No verified supplier data is currently available for this product category.

Performance Analysis

In the absence of specific supplier profiles, procurement focus should remain on regional capabilities and process verification. Historically, Zhejiang-based manufacturers demonstrate superior responsiveness in low-complexity woodcraft categories, often providing sample submissions within 7–10 days. Guangdong suppliers excel in mixed-material integration—combining wood with metal or fabric elements—for enhanced product functionality. When initiating sourcing activities, prioritize companies with demonstrable export experience to Western retail or e-commerce channels, as they are more likely to meet packaging, labeling, and regulatory requirements for international markets.

FAQs

How to verify supplier reliability for wooden craft items?

Validate business licenses and cross-check certifications with issuing bodies. Request audit trails covering wood sourcing (to confirm legality and sustainability), factory workflow documentation, and past shipment records. Analyze customer feedback focusing on defect rates, color consistency, and packaging durability during transit.

What is the typical sampling timeline?

Standard samples take 7–14 days to produce, depending on design complexity. Items requiring custom molds or multi-step finishing may require up to 21 days. Add 5–9 days for international air shipping. Sample costs typically range from $30–$100, often creditable against future bulk orders.

Can suppliers ship wooden products worldwide?

Yes, experienced exporters handle global logistics, including ISPM 15-compliant palletization for intercontinental shipments. Confirm Incoterms (FOB, CIF) early in negotiations and ensure phytosanitary certificates are provided where required by destination countries to prevent customs delays.

Do manufacturers offer free samples?

Free samples are uncommon for customized designs. Some suppliers waive fees for repeat buyers or for orders exceeding 500 units. Standard catalog items may be offered at reduced cost to facilitate evaluation.

How to initiate customization requests?

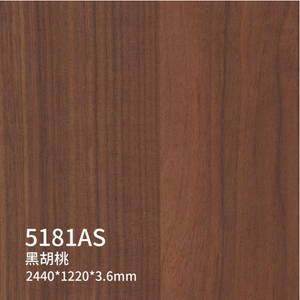

Submit detailed specifications including preferred wood type (e.g., birch, bamboo, pine), dimensions, joinery method, finish type (natural oil, lacquer, painted), and artwork files in vector format. Reputable suppliers will provide digital mockups within 48 hours and revised quotes within 3–5 business days.