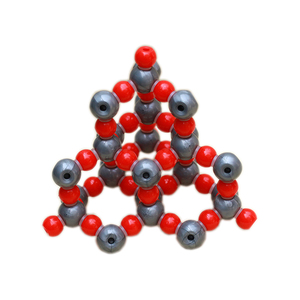

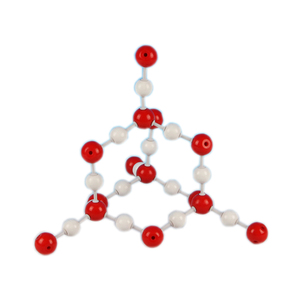

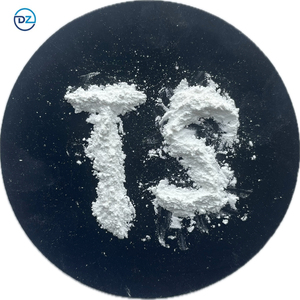

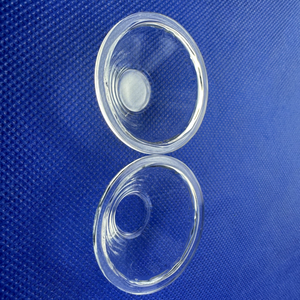

Sio2 Structure

1/1

1/1

1/11

1/11

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/19

1/19

1/3

1/3

1/1

1/1

1/3

1/3

1/3

1/3

1/6

1/6

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

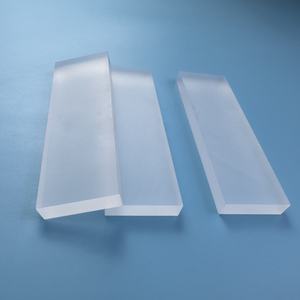

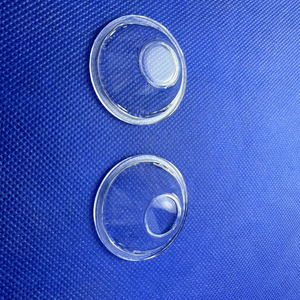

About sio2 structure

Where to Find SiO2 Structure Suppliers?

Global production of SiO2 (silica) structural materials is concentrated in industrialized regions of East Asia, particularly China’s Jiangsu and Zhejiang provinces, which host specialized chemical and advanced materials manufacturing zones. These clusters integrate high-purity raw material processing with precision fabrication capabilities, enabling cost-efficient production of crystalline and amorphous SiO2 structures used in semiconductors, optical components, and composite materials. Proximity to silicon feedstock suppliers and port infrastructure supports streamlined export logistics, reducing transit times by 10–15% compared to non-regional producers.

The ecosystem benefits from vertically integrated supply chains encompassing quartz purification, thermal or sol-gel synthesis, and CNC micromachining. This integration allows for consistent control over stoichiometry, porosity, and structural integrity. Buyers can expect lead times of 25–40 days for standard SiO2 components, with localized sourcing cutting material costs by 18–25% due to economies of scale and reduced import tariffs within ASEAN and RCEP trade frameworks. Custom configurations, including doped silica or nanostructured frameworks, are feasible through collaboration with facilities equipped with cleanroom environments and spectroscopic monitoring systems.

How to Choose SiO2 Structure Suppliers?

Implement the following verification protocols to ensure technical and operational reliability:

Material & Process Certification

Confirm compliance with ISO 9001 for quality management and ISO 14001 for environmental controls in high-temperature processing. For electronics and photonic applications, require IEC 60688 or SEMI F57 standards validation. Verify batch-specific certificates of analysis (CoA) detailing SiO2 purity (≥99.9%), trace metal content (e.g., Fe <1 ppm), and hydroxyl group concentration in fused forms.

Production Infrastructure Assessment

Evaluate supplier capabilities based on:

- Minimum 3,000m² controlled-environment facility with Class 10,000 (ISO 7) cleanroom zones

- In-house capacity for thermal CVD, flame hydrolysis, or sol-gel processing

- Advanced metrology tools: FTIR, XRD, and ellipsometry for structural characterization

Cross-reference facility specifications with documented yield rates (>92%) and defect density metrics to assess consistency.

Quality Assurance & Transaction Security

Require adherence to AQL Level II inspection protocols and third-party testing via SGS or TÜV for critical orders. Utilize secure transaction models that withhold final payment until independent lab verification of refractive index, thermal expansion coefficient, and mechanical strength. Pre-shipment sampling should include accelerated aging tests (85°C/85% RH for 1,000 hours) to evaluate long-term stability.

What Are the Best SiO2 Structure Suppliers?

No verified suppliers are currently listed in the database for SiO2 structure manufacturing. Procurement professionals are advised to conduct direct audits of potential partners using the criteria outlined above. Focus on manufacturers demonstrating proven export experience to North America, Europe, or Japan, as these markets enforce stringent material traceability and process documentation requirements. Prioritize companies providing full lifecycle data—from raw quartz sourcing to final packaging—to mitigate contamination and performance risks.

Performance Analysis

In the absence of published supplier data, risk mitigation hinges on proactive due diligence. Leading candidates typically maintain R&D teams comprising ≥15% of technical staff and publish peer-reviewed process improvements in materials science journals. Facilities investing in automated handling and AI-driven process control demonstrate higher reproducibility in complex geometries and doping profiles. Buyers should request video audits, real-time production monitoring access, and historical batch records to validate claims before engagement.

FAQs

How to verify SiO2 structure supplier reliability?

Validate certifications through issuing bodies and request redacted audit reports covering raw material traceability, furnace calibration logs, and QC test results. Assess responsiveness to technical inquiries—reliable suppliers provide detailed process flowcharts and material compatibility assessments within 24 hours.

What is the average sampling timeline?

Standard SiO2 samples require 20–30 days for synthesis and machining. Complex forms (e.g., photonic crystals or graded-index structures) may take 45–60 days. Air freight adds 5–9 days for international delivery. Sample costs typically reflect 40–60% of unit production value, often creditable against future orders exceeding 50 units.

Can suppliers ship SiO2 structures worldwide?

Yes, experienced exporters manage global shipments under EXW, FOB, or DDP terms. Ensure proper packaging with humidity indicators and shock sensors for fragile or high-purity components. Confirm compliance with destination regulations, especially for shipments requiring ITAR or EAR classification in semiconductor-grade materials.

Do manufacturers provide free samples?

Free samples are uncommon due to high processing costs. Some suppliers waive fees for qualified buyers committing to annual volumes exceeding 200 kg or placing trial orders above $15,000. Expect nominal charges for shipping and handling even in waived-production-cost scenarios.

How to initiate customization requests?

Submit detailed technical parameters including desired morphology (bulk, thin film, aerogel), density range, dopants (e.g., GeO2, P2O5), and dimensional tolerances (±0.01mm typical). Reputable partners respond with feasibility assessments, CAD models, and proposed process validation plans within 5 business days.