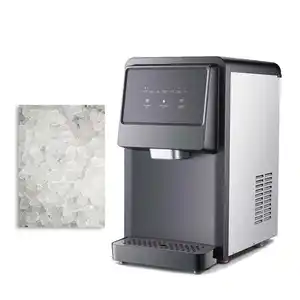

Small Ice Nugget Maker

About small ice nugget maker

Where to Find Small Ice Nugget Maker Suppliers?

China remains the dominant hub for small ice nugget maker manufacturing, with key production clusters concentrated in Zhejiang, Jiangsu, and Guangdong provinces. These regions host vertically integrated supply chains that specialize in compact refrigeration appliances, leveraging localized access to compressors, evaporators, and injection-molded components. Ningbo and Shanghai in the Yangtze River Delta offer mature logistics networks and proximity to port infrastructure, enabling efficient export operations to North America, Europe, and Southeast Asia.

The industrial ecosystem supports both high-volume OEM/ODM production and agile prototyping for niche markets. Facilities in these zones typically operate automated assembly lines capable of producing 10,000–50,000 units per month, depending on model complexity. Economies of scale reduce component procurement costs by 15–25% compared to offshore alternatives, while shared technical expertise in thermodynamics and food-safe materials enhances product reliability. Buyers benefit from shorter development cycles—average time from design approval to first shipment ranges between 30–45 days for standard configurations.

How to Choose Small Ice Nugget Maker Suppliers?

Procurement decisions should be guided by structured evaluation criteria focused on operational capability, compliance, and transaction security:

Technical & Production Capacity

Assess suppliers based on verified infrastructure metrics:

- Minimum factory area exceeding 3,000m² for sustained output

- In-house engineering teams supporting custom design (e.g., color, size, logo imprinting)

- Integration of core components such as rotary evaporators, condenser coils, and food-grade ABS plastic molds

Cross-reference product listings with delivery performance; prioritize suppliers maintaining ≥96% on-time shipment rates.

Quality Assurance Standards

Confirm adherence to international safety and environmental regulations. While explicit certification data is not provided, buyers must require documentation for CE, RoHS, and UL standards during due diligence. Validate electrical safety testing for compressor-driven models operating at 110V–220V ranges. Request third-party lab reports verifying noise levels (typically ≤45 dB) and energy consumption (average 100–150W per cycle).

Order Flexibility and Transaction Security

Evaluate minimum order quantities (MOQs), pricing transparency, and payment protection mechanisms. Most suppliers in this category require MOQs between 50–500 units, though some offer single-unit sampling. Leverage platforms with escrow services to mitigate financial risk. Prioritize partners offering customization options across color, packaging, labeling, and branding elements without significant tooling surcharges.

What Are the Best Small Ice Nugget Maker Suppliers?

| Company Name | Location | Online Revenue (USD) | On-Time Delivery | Avg. Response Time | Reorder Rate | Customization Options | Product Range (Listings) | Notable Features |

|---|---|---|---|---|---|---|---|---|

| Ningbo Yutong Electric Appliance Co., Ltd. | Zhejiang, CN | $700+ | 100% | ≤1h | <15% | Color, material, size, logo, packaging, label, graphic | 4 | Mid-range pricing ($40–73); multiple compact designs |

| Nantong Bolang Energy Saving Technology Co., Ltd. | Jiangsu, CN | $200,000+ | 96% | ≤2h | <15% | Color, material, size, logo, packaging, label, graphic | 5 | Commercial-grade models; wide capacity range (25–400kg/day) |

| Guangzhou Universal Venture Holding Co., Ltd | Guangdong, CN | $260,000+ | 100% | ≤8h | 33% | Not specified | 5 | Low entry price point ($33.60); broad commercial applicability |

| Shanghai Snowdream Refrigeration Equipment Co., Ltd. | Shanghai, CN | $640,000+ | 100% | ≤3h | 20% | Not specified | 5 | Largest product portfolio (778+ ice machines); industrial focus |

| Ningbo Yingyi International Trade Co., Ltd. | Zhejiang, CN | $210,000+ | 100% | ≤2h | 16% | Color, size, logo, packaging, label, graphic | 5 | Competitive MOQs (100 pcs); lowest quoted prices ($38–41) |

Performance Analysis

Suppliers vary significantly in specialization and market positioning. Ningbo-based companies emphasize responsiveness and customization agility, with two achieving sub-2-hour average reply times. Nantong Bolang and Shanghai Snowdream offer scalable production with broader technical scope, including higher-capacity commercial units. Guangzhou Universal presents aggressive pricing but slower response cycles, suggesting potential bottlenecks in customer service infrastructure. Shanghai Snowdream stands out with a dominant catalog presence in ice-making equipment, indicating deep domain expertise despite higher entry cost points.

Buyers seeking budget-friendly entry into retail or hospitality markets may favor Ningbo Yingyi’s $38–41 price band, whereas operators requiring durable commercial deployment should evaluate Nantong Bolang’s 25–400kg/day systems. All top-tier suppliers maintain 100% on-time delivery except Nantong Bolang (96%), a minor deviation within acceptable industry variance.

FAQs

What are typical MOQs for small ice nugget makers?

Minimum order quantities range from 1 piece for sample validation to 500 pieces for bulk pricing. Some suppliers accept orders as low as 100 units at slightly elevated per-unit costs. Negotiation leverage increases significantly above 1,000-unit commitments.

How long does production and shipping take?

Manufacturing lead time averages 30–45 days post-design confirmation. Air freight delivers samples within 7–10 days internationally, while sea freight requires 25–35 days depending on destination port congestion and customs processing.

Can suppliers customize appearance and branding?

Yes, multiple suppliers explicitly list customization capabilities for color, logo placement, packaging design, and user label graphics. Material substitutions (e.g., antimicrobial coatings) may incur additional tooling fees and extended timelines.

Are electrical specifications adaptable for global markets?

Most manufacturers support dual-voltage configurations (110V/220V) and can modify plug types (NEMA, BS, EU) upon request. Final compliance with regional electrical codes must be confirmed through pre-shipment product testing.

Is sample testing recommended before full-scale ordering?

Essential. Procure physical samples to assess build quality, ice production rate (typically 9–26 lbs/24h), noise level, and user interface intuitiveness. Benchmark against competing models to validate performance claims prior to volume commitment.