Smart Factory Automation World 2021

1/5

1/5

1/2

1/2

1/27

1/27

1/28

1/28

1/46

1/46

1/16

1/16

About smart factory automation world 2021

Where to Find Smart Factory Automation Suppliers?

China remains a central hub for smart factory automation solutions, with key suppliers concentrated in industrial regions such as Zhejiang, Shandong, and Guangdong. These provinces host integrated manufacturing ecosystems that support rapid development of intelligent machinery and IoT-enabled control systems. Zhejiang specializes in high-precision automated textile equipment, leveraging local expertise in computerized motion control and pattern recognition. Shandong has emerged as a center for industrial robotics and welding automation, benefiting from proximity to heavy manufacturing zones and steel supply chains.

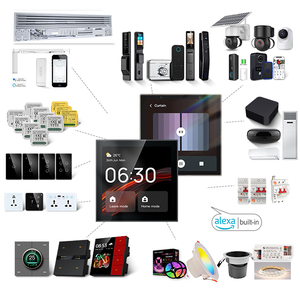

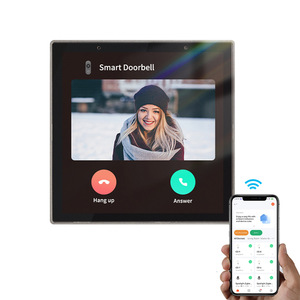

The Pearl River Delta, particularly Shenzhen, dominates production of smart home and building automation systems—components often integrated into broader smart factory environments for facility management and energy optimization. This region offers access to mature electronics supply chains, enabling fast prototyping and scalable assembly of Wi-Fi, Zigbee, and Tuya-compatible controllers. Suppliers here typically operate within vertically aligned clusters where PCB fabrication, firmware programming, and final testing occur within tight geographic proximity, reducing lead times by up to 30% compared to decentralized production models.

How to Choose Smart Factory Automation Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & System Integration

Verify adherence to international standards such as CE, RoHS, and ISO 9001. For smart control systems, confirm compatibility with major IoT platforms (e.g., Tuya, Alexa, Google Home) and communication protocols (Zigbee, Wi-Fi, Bluetooth). Request documentation on firmware update mechanisms, cybersecurity measures, and system interoperability with existing PLCs or SCADA networks.

Production Capability Assessment

Evaluate the supplier’s infrastructure using these benchmarks:

- Facility size exceeding 2,000m² for sustained output

- In-house R&D teams focused on automation software and hardware integration

- On-site CNC machining, robotic assembly, or PCB SMT lines

Cross-reference claimed capabilities with response time and on-time delivery metrics. Suppliers achieving ≤2-hour response times and 100% on-time fulfillment are more likely to maintain real-time operational oversight.

Quality Control & Transaction Security

Prioritize suppliers providing third-party verified performance data. Assess defect rates through reorder rate indicators—values above 20% suggest customer satisfaction with product reliability. Utilize secure payment mechanisms and require functional testing before shipment. For control systems, demand sample units preloaded with required firmware configurations to validate performance under actual operating conditions.

What Are the Best Smart Factory Automation Suppliers?

| Company Name | Main Products | Price Range (Unit) | MOQ | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| Zhejiang Juita Intelligent Technology Co., Ltd. | Computerized sewing machines, template-guided automation | $7,000–14,000 | 1 set | 100% | ≤12h | - | - |

| Shandong UMW Technology Co., Ltd. | Robotic welding arms, industrial welding automation | $3,400–3,800 | 1 set | 100% | ≤2h | 29% | US $700,000+ |

| Shenzhen Lona Technology Co., Ltd. | Smart home automation systems (Tuya/Wi-Fi) | $57–104.50 | 1 piece | 82% | ≤2h | 20% | US $10,000+ |

| Shenzhen Huayi Technology Co., Ltd. | Home automation controls, Zigbee/Goggle-compatible systems | $350–580 | 1 set | 100% | ≤8h | 50% | US $5,000+ |

| I C T S (MYANMAR) LIMITED | Smart home security systems, Alexa-integrated locks | $310–500 | 1–10 pieces | - | ≤8h | - | - |

Performance Analysis

Zhejiang Juita represents a specialized player in garment industry automation, offering high-value computerized sewing systems priced between $7,000 and $14,000 per set. Their 100% on-time delivery record indicates strong production planning, though limited responsiveness may affect urgent order adjustments. Shandong UMW stands out in industrial robotics with competitive pricing and robust online sales volume (over $700,000), supported by rapid ≤2h response times and proven reordering behavior (29%).

Among smart control system providers, Shenzhen Huayi achieves the highest reorder rate (50%), suggesting strong end-user satisfaction despite moderate revenue volume. Shenzhen Lona offers entry-level smart automation kits at low MOQs but exhibits lower delivery reliability (82%). I C T S (MYANMAR) LIMITED targets niche export markets with customizable smart home solutions but lacks verifiable transaction metrics, increasing procurement risk.

FAQs

How to verify smart factory automation supplier reliability?

Cross-check certifications (CE, RoHS, ISO) with official databases. Request evidence of in-house testing facilities, including EMI/EMC reports for electronic controllers. Analyze customer feedback focusing on system stability, software updates, and technical support responsiveness.

What is the typical lead time for smart automation systems?

Standard orders take 20–35 days for production and quality inspection. Customized robotic cells or integrated control panels may require 45–60 days. Add 7–14 days for international air freight or 25–40 days for sea shipping depending on destination.

Can suppliers provide OEM/ODM services for automation products?

Yes, many suppliers offer customization of branding, interface design, communication protocols, and enclosure materials. Shandong UMW and I C T S (MYANMAR) LIMITED explicitly list logo, color, and packaging modification options. Minimum order thresholds vary—from 10 units for electronic modules to 50+ units for full machine rebranding.

Do smart automation suppliers support global compliance requirements?

Leading suppliers design products to meet CE and FCC standards for European and North American markets. Confirm inclusion of certified power adapters, multilingual user interfaces, and voltage compatibility (110V–240V). For industrial robots, ensure safety compliance with ISO 10218 or equivalent regional regulations.

How to assess scalability of automation suppliers?

Evaluate monthly output capacity, availability of modular designs, and inventory of critical components like servo motors or IoT modules. Suppliers with documented revenue streams and consistent reorder rates are better positioned to handle volume increases without compromising delivery timelines.