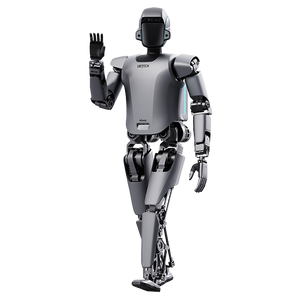

Smart Factory Robot

Top sponsor listing

Top sponsor listing

About smart factory robot

Where to Find Smart Factory Robot Suppliers?

China leads global production of smart factory robotics, with concentrated manufacturing hubs in Guangdong and Jiangsu provinces driving innovation and scale. Guangzhou and Dongguan serve as core centers for intelligent automation equipment, hosting vertically integrated supply chains that support rapid prototyping and mass production. These regions benefit from proximity to semiconductor, sensor, and precision motor suppliers, reducing component lead times by 20–35% compared to offshore alternatives.

The industrial ecosystem enables streamlined development of autonomous mobile robots (AMRs), automated guided vehicles (AGVs), robotic arms, and specialized service robots. Integrated logistics networks allow for efficient export via Shenzhen and Guangzhou ports, supporting FOB and CIF shipping globally. Key advantages include scalable production capacity, flexible customization options, and cost efficiency—typical unit costs are 25–40% lower than equivalent European or North American-built systems, particularly for material handling and warehouse automation solutions.

How to Choose Smart Factory Robot Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical & Functional Validation

Confirm compatibility with Industry 4.0 standards, including IoT connectivity (Wi-Fi/5G), AI-driven navigation (SLAM algorithms), and interoperability with existing MES/SCADA systems. For AGVs and AMRs, verify payload capacity, battery life (≥8 hours continuous operation), and obstacle detection accuracy. Robotic manipulators should meet ISO 9787 compliance for kinematic performance. Request system schematics, software interface documentation, and proof of CE or FCC certification where applicable.

Production & Engineering Capacity

Assess core capabilities through the following benchmarks:

- Minimum R&D team size of 10 engineers focused on control systems, vision processing, or motion planning

- In-house design and assembly of critical subsystems (e.g., drive modules, control boards)

- Monthly output capacity exceeding 200 units for high-volume applications

Cross-reference product listing diversity with reorder rates and response times to gauge operational stability and customer satisfaction.

Quality Assurance & Transaction Security

Prioritize suppliers with documented quality management systems, ideally ISO 9001 certified. Verify on-time delivery performance (target ≥95%) and response time (≤2 hours) as indicators of service reliability. Utilize secure payment mechanisms such as escrow services for initial orders. Conduct pre-shipment inspections or request third-party testing reports for functional validation, especially for customized configurations.

What Are the Best Smart Factory Robot Suppliers?

| Company Name | Main Products (Listings) | Customization Options | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Robotphoenix Intelligent Technology Co.,Ltd | Manipulator (588); AGV (209); Parallel Robots (148) | Not specified | 100% | 100% | ≤2h | $30,000+ | 1 set | $2,300–$12,000 |

| Dongguan Juke Industrial Development Co., Ltd. | Electric Window Cleaners (107) | Not specified | 100% | <15% | ≤1h | $40,000+ | 100 sets | $25–$36 |

| Xiangjing (Shanghai) Mechanical And Electrical Tech Co., Ltd. | Humanoid Robots; Vision-Guided Robots; AMRs | Color, material, size, logo, packaging, graphics | 100% | 20% | ≤7h | $50,000+ | 1 piece/unit | $25,200–$99,999 |

| Guangzhou Inbot Technology Ltd. | Commercial Reception Robots (22); Delivery Robots (21) | Color, material, size, logo, packaging, graphics, photos | 66% | <15% | ≤2h | $140,000+ | Not specified | Not specified |

| HK Geerlepol Intelligent Technology Co., Ltd. | Robot Vacuums (509); Cleaning Systems | Not specified | 100% | - | ≤2h | $1,000+ | 1–2 pieces | $53–$230 |

Performance Analysis

Robotphoenix stands out with a 100% reorder rate and broadest industrial robot portfolio, indicating strong customer retention and engineering maturity. Dongguan Juke offers high responsiveness (≤1h) and consistent on-time delivery, suitable for standardized automation tools like window-cleaning robots. Xiangjing (Shanghai) targets premium applications with high-value units ($25K–$100K), offering extensive customization but slower response cycles. Guangzhou Inbot generates the highest online revenue, though its 66% on-time delivery rate presents a risk for time-sensitive deployments. HK Geerlepol specializes in floor-cleaning automation with low MOQs, ideal for pilot testing or small-scale integration.

FAQs

What certifications should smart factory robot suppliers have?

Essential certifications include CE (EU safety), FCC (EMC compliance for U.S. markets), and ISO 9001 (quality management). For industrial environments, IEC 61508 functional safety standards may apply. Request test reports for electrical components, battery systems, and wireless communication modules.

What is the typical lead time for smart robot orders?

Standard models: 15–30 days after deposit. Customized systems (AGVs with specific payloads or navigation logic): 45–60 days. Add 7–14 days for international air freight or 25–40 days for sea shipment depending on destination.

Can suppliers provide OEM/ODM services?

Yes, multiple suppliers offer full customization including branding (logo, color), structural modifications (size, material), and packaging design. Minimum order requirements vary—typically 100–500 units for hardware-level changes. Prototypes can be delivered within 3–4 weeks upon final specifications.

Are samples available before bulk ordering?

Sample availability depends on model complexity. Simple cleaning robots may be provided at 30–50% of unit cost, refundable against future orders. High-end AGVs or humanoid robots typically require direct negotiation due to development overhead. Buyers should budget $500–$5,000 for functional prototypes.

How to evaluate robot software and integration capability?

Request access to SDKs, API documentation, and sample code repositories. Validate support for common protocols (Modbus, MQTT, ROS). Test real-time data feedback, remote monitoring features, and ease of fleet management setup. Video demonstrations of deployment scenarios are recommended prior to procurement.