Smart Factory Solution

CN

CN

1/19

1/19

1/19

1/19

1/11

1/11

About smart factory solution

Where to Find Smart Factory Solution Suppliers?

China remains the central hub for smart factory solution manufacturing, with key industrial clusters concentrated in Shandong, Hunan, and Hunan provinces. These regions host vertically integrated ecosystems combining automation hardware, IoT integration, and intelligent storage systems. Shandong's Jinan and Qingdao zones specialize in autonomous mobile robots (AMRs) and automated warehousing systems, supported by robust machinery supply chains. Hunan’s Changsha and Zhuzhou areas focus on electronic glass, smart films, and sensor-integrated components critical for digitalized production environments.

The proximity of component manufacturers, R&D centers, and logistics networks enables rapid prototyping and scalable deployment. Suppliers benefit from localized access to CNC machining, PLC programming, and RFID module assembly, reducing lead times by 20–30% compared to offshore alternatives. Buyers can expect standard delivery windows of 15–45 days depending on customization level, with established suppliers offering modular solutions that integrate seamlessly into existing production lines.

How to Choose Smart Factory Solution Suppliers?

Selecting reliable partners requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Capabilities and Integration Expertise

Verify supplier experience in delivering end-to-end automation systems, including AGVs, smart lockers, inventory cabinets, and machine monitoring platforms. Confirm compatibility with Industry 4.0 protocols such as OPC UA, MQTT, and cloud-based SCADA systems. For hardware-focused solutions, assess engineering support for PLC, HMI, and wireless control integration.

Production Infrastructure Assessment

Evaluate the following benchmarks:

- Minimum facility size of 3,000m² for system-level integration and testing

- In-house design teams capable of customizing software interfaces, cabinet dimensions, or material handling workflows

- Proven track record in deploying turnkey warehouse management or production tracking systems

Cross-reference declared capabilities with on-time delivery performance—target suppliers maintaining ≥95% fulfillment rates.

Quality Assurance and Transaction Security

Prioritize suppliers with documented quality management systems. While formal ISO 9001 certification is not universally listed, consistent on-time delivery (100% reported by leading vendors) and responsive communication (response times ≤1 hour) indicate operational discipline. Utilize secure payment mechanisms and request functional prototypes or site demonstrations before large-scale deployment.

What Are the Best Smart Factory Solution Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Customization Options | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Jinan Hulk Machinery Co., Ltd. | AGVs, Mobile Robots, Unmanned Transport Systems | $1,684–40,000 | 1 unit/set | 100.0% | ≤1h | Color, size, logo, packaging, material | $580,000+ | <15% |

| Changsha Kenwei Intelligent Technology Co., Ltd. | Smart Silos, Vertical Carousels, Automated Storage | $12,000–60,000 | 1 set | 100.0% | ≤3h | N/A | - | - |

| Global Health Technology & Services Co., Ltd. | Smart Material Handling, RFID Lockers, Inventory Cabinets | $1,119–3,999 | 1 piece | 100.0% | ≤1h | Color, size, logo, packaging, graphic | $60,000+ | <15% |

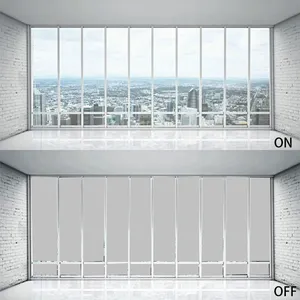

| Hunan Haozhi Technology Co., Ltd. | PDL C Smart Films, Switchable Privacy Glass | $30–120 | 1–10 m² | 92.0% | ≤9h | N/A | $10,000+ | <15% |

| INTELLISENSE TECHNOLOGY | IoT Sensors, PCBAs, Wearables, AI Monitoring | $6–399 | 6–99 pieces | - | ≤4h | N/A | - | - |

Performance Analysis

Jinan Hulk Machinery and Global Health Technology stand out for high responsiveness (≤1h), 100% on-time delivery, and strong customization flexibility—critical for integrating smart solutions into diverse factory layouts. Changsha Kenwei offers premium automated storage systems at higher price points ($12k–$60k), indicating specialization in large-scale installations. Hunan Haozhi focuses on smart film technology with lower entry costs but slower response cycles. INTELLISENSE TECHNOLOGY provides low-cost IoT enablers like ESP32 modules and wearable PCBs, suitable for pilot deployments or edge device integration. Suppliers with verified revenue streams and documented delivery performance are recommended for mission-critical implementations.

FAQs

How to verify smart factory solution supplier reliability?

Assess on-time delivery history, average response time, and presence of customization options as proxies for operational maturity. Request case studies or video demonstrations of deployed systems. Validate technical claims through direct testing of sample units or remote audits of control software interfaces.

What is the typical MOQ and pricing structure?

MOQs vary significantly: AGVs and storage systems typically require 1 unit/set, while electronic components like smart films or PCBs start at 1–10 m² or 6–99 units. Prices range from $6 per PCB module to over $60,000 for full silo systems. High-value orders often allow negotiation on delivery terms and integration support.

Do suppliers offer customization?

Yes, select suppliers—particularly Jinan Hulk Machinery and Global Health Technology—offer extensive customization in color, size, branding, materials, and packaging. Custom software interfaces or mechanical adaptations may require NRE fees and longer lead times (4–8 weeks).

Are smart factory solutions compatible with existing production systems?

Compatibility depends on supplier expertise. Top-tier vendors provide API access, cloud connectivity, and support for standard industrial communication protocols. Confirm interoperability with your current MES, ERP, or SCADA platforms prior to procurement.

What are the lead times for smart factory equipment?

Standard products ship within 15–30 days. Customized systems, especially automated storage or multi-robot fleets, may require 45–60 days for engineering, assembly, and testing. Expedited timelines are possible with confirmed production capacity and deposit payments.