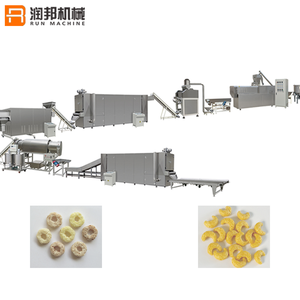

Snacks Processing Machine

CN

CN

About snacks processing machine

Where to Find Snacks Processing Machine Suppliers?

China leads global production of snacks processing machinery, with concentrated manufacturing hubs in Shandong and Henan provinces offering strategic advantages. Shandong's Jinan and Jiaozuo regions specialize in extrusion-based systems for puffed, fried, and 3D-shaped snacks, supported by integrated supply chains for stainless steel and electromechanical components. These clusters enable cost reductions of 15–25% compared to Western manufacturers due to localized sourcing and energy-efficient production ecosystems.

The industrial zones feature vertically integrated facilities capable of delivering turnkey solutions—from single machines to full automated lines—within 30–60 days. Suppliers benefit from co-located engineering teams, CNC fabrication units, and testing labs within 5-kilometer radii, ensuring rapid prototyping and validation. Buyers gain access to scalable production networks that support both low-volume trials (1–5 sets) and high-capacity orders (>50 sets monthly), with standard lead times averaging 45 days for customized configurations.

How to Choose Snacks Processing Machine Suppliers?

Implement the following verification protocols to ensure supplier reliability:

Technical Compliance

Confirm adherence to international safety and quality benchmarks such as CE or ISO 9001. For export markets, verify compliance documentation for electrical systems (e.g., 110V/220V configurations) and food-contact materials (e.g., SUS304 stainless steel). Request test reports on critical performance metrics including extrusion pressure stability, temperature control accuracy, and oil circulation efficiency in frying modules.

Production Capability Assessment

Evaluate operational scale and technical depth:

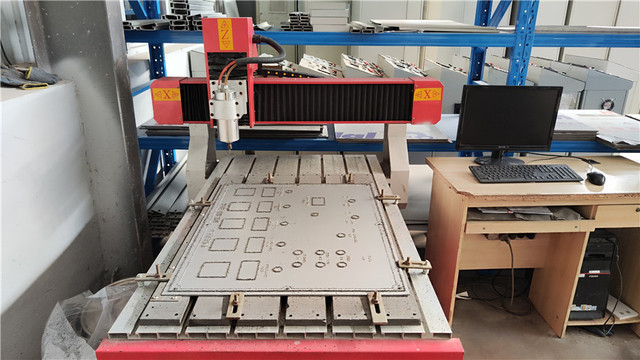

- Facilities exceeding 3,000m² indicate capacity for full-line assembly

- In-house R&D teams suggest design flexibility for custom snack profiles

- Integrated CNC machining and welding capabilities reduce third-party dependencies

Cross-reference delivery performance (target ≥98%) with order volume history to assess scalability under load.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services until post-delivery inspection is completed. Prioritize suppliers with documented after-sales service frameworks, including remote diagnostics and spare parts availability. Conduct sample testing to validate output consistency—benchmark against industry standards for expansion ratio, moisture content, and texture uniformity before scaling procurement.

What Are the Best Snacks Processing Machine Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization |

|---|---|---|---|---|---|---|---|---|

| Shandong Tianfen Information Technology Co., Ltd. | Other Snack Machines, Mixing Equipment, Grinding Equipment | $45–$90 | 1 set | 100% | ≤2h | <15% | US $40,000+ | Limited |

| Jinan Phenix Machinery Co., Ltd. | Food Processing Lines, Feed & Bean Machinery | $8,000–$55,000 | 1 set | 100% | ≤11h | 100% | US $40,000+ | High (Core-filling, Extrusion) |

| Jiaozuo Dingchang Machinery Equipment Co., Ltd. | Puff Snack Makers, Corn Extruders | $90–$1,950 | 1 set | 100% | ≤2h | <15% | US $130,000+ | Yes (Color, Size, Logo, Packaging) |

| Shandong Fuyun Group Co., Ltd. | Puffed Snack Lines, Fryers, Baking Ovens | $999–$2,499 | 1 set | 100% | ≤3h | <15% | US $7,000+ | Moderate (Stick Chips, Bugles) |

| Jinan Run Machinery Co., Ltd. | Snack Food Processing Lines, Extruders | $6,000–$31,000 | 1 piece | 100% | ≤8h | - | - | Full Line Customization |

Performance Analysis

Jinan Phenix Machinery stands out with a 100% reorder rate, indicating strong customer retention likely driven by reliable performance in core-filling and full-automatic fried pellet lines. Jiaozuo Dingchang leads in customization breadth, offering branding integration across packaging and machine labeling. While several suppliers offer entry-level equipment below $100, premium-tier providers like Jinan Run and Phenix focus on engineered systems priced above $8,000, targeting commercial-scale operations requiring precise process control. Response efficiency is strongest among Shandong-based firms, with three achieving sub-3-hour average reply times—critical for resolving technical queries during commissioning phases.

FAQs

How to verify snacks processing machine supplier reliability?

Validate certifications through official registries and request factory audit reports covering material traceability, weld integrity, and electrical safety. Analyze transaction records for consistent fulfillment patterns and review client testimonials focused on uptime, ease of maintenance, and technical support responsiveness.

What is the typical sampling timeline?

Standard machine samples require 15–25 days for production. Complex configurations involving multi-stage extrusion or integrated frying conveyors may take 35–50 days. Air freight adds 7–12 days for international delivery, depending on destination region.

Can suppliers ship globally?

Yes, established manufacturers manage worldwide logistics via sea or air freight. Confirm Incoterms (FOB, CIF) upfront and verify compatibility with local voltage standards and food safety regulations (e.g., FDA, EU 1935/2004). Sea shipping remains optimal for complete production lines due to lower cost per unit.

Do suppliers offer free samples?

Free samples are uncommon for capital equipment. Most suppliers charge 30–50% of unit cost for trial units, which may be credited toward bulk orders. Exceptions exist for qualified buyers placing contracts exceeding five units.

How to initiate customization requests?

Submit detailed specifications including desired snack type (puffed, wafer, filled), raw materials (corn, wheat, potato), output capacity (kg/h), power requirements (single/three-phase), and dimensional constraints. Leading suppliers provide CAD layouts within 72 hours and functional prototypes within 3–5 weeks.