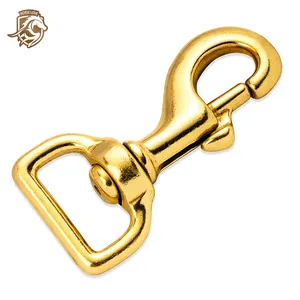

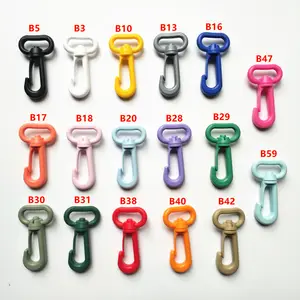

Snap Hooks

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

1/24

1/24

1/1

1/1

1/3

1/3

CN

CN

1/3

1/3

1/3

1/3

0

0

1/14

1/14

1/3

1/3

1/10

1/10

1/39

1/39

1/21

1/21

0

0

0

0

1/3

1/3

0

0

1/30

1/30

About snap hooks

Where to Find Snap Hooks Suppliers?

China remains the global epicenter for snap hook manufacturing, with key production clusters concentrated in Zhejiang, Guangdong, and Fujian provinces. These regions host vertically integrated supply chains combining die-casting, stamping, surface treatment, and assembly under one roof, enabling rapid turnaround and cost efficiency. Zhejiang excels in high-strength hardware for outdoor and industrial applications, leveraging advanced CNC machining and aerospace-grade aluminum processing. Guangdong’s Pearl River Delta zone specializes in decorative and functional hardware for bags, apparel, and pet products, supported by robust plastic injection and plating infrastructure. Fujian-based suppliers focus on mid-volume export orders with competitive pricing, particularly in zinc alloy and stainless steel variants.

The industrial ecosystem allows for economies of scale, with many suppliers operating facilities exceeding 3,000m² and monthly production capacities ranging from 500,000 to over 2 million units depending on complexity. Lead times for standard items typically range from 15–30 days, while customized orders require 25–40 days including tooling and sample validation. This integration supports both bulk procurement and low-MOQ sampling, making the region ideal for B2B buyers across outdoor gear, fashion accessories, and pet product sectors.

How to Choose Snap Hooks Suppliers?

Effective supplier selection requires systematic evaluation across three critical dimensions:

Quality & Compliance Verification

Prioritize suppliers with documented adherence to ISO 9001 quality management systems, especially those serving EU and North American markets where RoHS and REACH compliance are mandatory. For load-bearing applications (e.g., climbing, pet leashes), verify break strength testing protocols—some manufacturers provide DIN or CE-certified mechanical performance data. Request material composition reports, particularly for nickel-free or hypoallergenic finishes required in consumer goods.

Production & Customization Capacity

Assess technical capabilities through the following indicators:

- In-house mold-making and tooling departments for custom designs

- Surface treatment options: electroplating (nickel, chrome, brass), powder coating, anodizing

- Material expertise: zinc alloy, aluminum alloy, stainless steel, brass

- Digital proofing and 3D rendering support for logo, shape, and color customization

Cross-reference product listings with reorder rates (>15%) and on-time delivery performance (target ≥97%) as proxies for operational reliability.

Transaction Security & Communication Efficiency

Favor suppliers with response times under 3 hours and verified transaction histories. MOQs vary significantly—from as low as 2 pieces for samples to 100+ for production runs—offering flexibility for startups and large brands alike. Use incremental ordering strategies to validate quality before scaling. Confirm packaging and labeling customization options if private branding is required.

What Are the Best Snap Hooks Suppliers?

| Company Name | Main Products (Listings) | Customization Options | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Key Strengths |

|---|---|---|---|---|---|---|---|

| Quanzhou Horse Love Trading Corp., Ltd. | Hooks (358); Other Hardware (252) | Color, size, logo, packaging, label, graphic | 100% | 18% | ≤3h | US $60,000+ | High product diversity; strong customization suite |

| Dongguan Shen Wan Hardware Plastic Co., Ltd. | Special Bag Parts & Accessories (235) | Limited | 100% | 17% | ≤2h | US $30,000+ | Bag hardware specialization; fast response |

| Yiwu Baichao Outdoor Products Co., Ltd. | Hooks (174); Camping & Hiking (48) | Size, material, color | 97% | <15% | ≤3h | US $10,000+ | Outdoor-focused; aluminum alloy expertise |

| Dongguan King Hong Industrial Co., Ltd. | Custom metal hardware | Color, material, size, logo, packaging | 82% | 18% | ≤6h | US $1,700,000+ | Highest revenue; GRS/ISO9001-aligned |

| Zhejiang Jinrui Hardware Rigging Co., Ltd. | Climbing, auto, and rigging hooks | Color, load, material, size, lock, logo | 98% | <15% | ≤2h | US $110,000+ | High-load engineering; screw-lock mechanisms |

Performance Analysis

Dongguan King Hong leads in sales volume and customization depth, indicating strong OEM/ODM capabilities despite a lower on-time delivery rate (82%), warranting closer logistics scrutiny. Zhejiang Jinrui stands out for technical precision, offering load-rated and locking snap hooks suitable for safety-critical applications. Quanzhou Horse Love provides broad catalog coverage with extensive branding options, ideal for accessory brands requiring aesthetic consistency. Yiwu Baichao and Zhejiang Jinrui demonstrate superior delivery reliability (≥97%) and responsiveness, making them preferred partners for time-sensitive replenishment. Buyers should align supplier selection with application requirements: lightweight fashion hardware vs. engineered load-bearing components.

FAQs

What materials are commonly used in snap hooks?

Zinc alloy dominates due to its balance of strength, castability, and cost. Aluminum alloy is preferred for lightweight outdoor and climbing gear. Stainless steel and brass are used in marine or corrosion-resistant applications. Material choice directly impacts break strength, weight, and plating durability.

What is the typical MOQ for snap hooks?

MOQs range from 2 pieces (samples) to 100–500 units for standard production runs. Custom tooling may require minimum orders of 5,000+ units depending on complexity. Some suppliers offer tiered pricing that scales with volume.

How long does customization take?

Sample lead time for custom designs is 7–15 days, including mold adjustments and finish testing. Full production follows in 20–35 days after approval. Digital proofs are typically provided within 48 hours of order confirmation.

Can suppliers provide test reports for load capacity?

Yes, reputable manufacturers conduct break load testing and can supply documentation, especially for D-shaped or screw-gate hooks rated above 10kN. Specify required test standards (e.g., UIAA, CE EN 362) during inquiry.

Are eco-friendly certifications available?

Some suppliers comply with GRS (Global Recycled Standard) and ISO9001 frameworks. For regulated markets, confirm RoHS and REACH compliance in writing and request material safety data sheets (MSDS) when applicable.