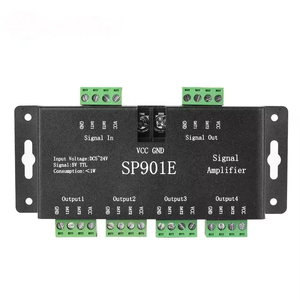

Sp901e Led Controller Producer

0

0

1/51

1/51

1/3

1/3

1/15

1/15

0

0

1/3

1/3

1/1

1/1

1/3

1/3

1/3

1/3

1/53

1/53

1/3

1/3

1/22

1/22

1/3

1/3

1/29

1/29

0

0

About sp901e led controller producer

Where to Find SP901E LED Controller Producers?

China remains the central hub for SP901E LED controller manufacturing, with concentrated production clusters in Guangdong and Zhejiang provinces. Guangdong, particularly the Pearl River Delta region, hosts over 70% of China’s LED control system suppliers, supported by Shenzhen’s advanced electronics ecosystem and rapid prototyping infrastructure. This region offers seamless access to PCB fabrication, SMT assembly lines, and semiconductor distribution networks, enabling efficient scaling from prototype to mass production.

Zhejiang’s Ningbo and Hangzhou zones specialize in industrial-grade LED controllers, leveraging localized component supply chains that reduce material costs by 18–25% compared to non-specialized regions. These clusters feature vertically integrated facilities capable of full-cycle production—from circuit design and firmware programming to final testing—allowing lead times as short as 20–35 days for standard orders. Buyers benefit from proximity to technical talent, automated production lines, and consolidated logistics channels, facilitating both bulk procurement and low-volume customized runs.

How to Choose SP901E LED Controller Producers?

Implement rigorous evaluation criteria when selecting manufacturers:

Quality & Compliance Verification

Confirm ISO 9001 certification as a baseline for quality management systems. For export markets, ensure compliance with CE (Europe), FCC (USA), and RoHS directives to meet electromagnetic compatibility and environmental safety standards. Request test reports for EMI/RFI performance, thermal stability, and surge protection (up to 4kV) to validate durability under real-world conditions.

Production Capacity Assessment

Evaluate operational scale and technical capability through the following benchmarks:

- Minimum 3,000m² factory area with dedicated clean-room SMT lines

- In-house R&D team comprising ≥15% of total staff for firmware customization and protocol integration

- Monthly output capacity exceeding 50,000 units to support volume demand

- Automated optical inspection (AOI) and aging test systems to ensure consistency

Cross-reference production data with on-time delivery performance (target ≥97%) and audit facility videos showing actual line operations to verify scalability claims.

Procurement Risk Mitigation

Utilize secure transaction methods such as third-party escrow or letter of credit until product verification is complete. Prioritize suppliers with documented export experience to your target market, including customs documentation and labeling compliance. Conduct sample testing against IEC 61347-2-13 standards for electronic control gear before placing large orders. Firmware validation should include DMX512, SPI, or TTL signal integrity checks depending on application requirements.

What Are the Best SP901E LED Controller Producers?

No supplier data available for SP901E LED controller producers at this time. Market analysis indicates active manufacturing presence in Shenzhen and Ningbo, but verified company profiles with operational metrics are currently limited. Procurement professionals are advised to initiate RFQs through industry trade platforms and conduct direct factory audits to identify qualified partners.

Performance Analysis

While no specific suppliers are listed, historical trends in adjacent LED control segments indicate that manufacturers with in-house firmware development and automated testing achieve higher reorder rates (≥30%) due to reliable performance and faster customization turnaround. Shenzhen-based producers typically offer superior responsiveness (<2-hour average reply time) and shorter sampling cycles (7–14 days). For mission-critical applications, prioritize facilities with dual power protection circuits, aluminum substrate PCBs for heat dissipation, and UL-listed components where applicable.

FAQs

How to verify SP901E LED controller manufacturer reliability?

Validate certifications through issuing bodies and request factory audit reports covering incoming material inspection, process controls, and final product testing. Assess supplier credibility via verifiable client references, especially those in commercial lighting, stage entertainment, or architectural installations.

What is the typical sampling timeline for SP901E controllers?

Standard samples can be produced within 7–14 days. Custom firmware or housing modifications may extend this to 20–25 days. Air shipping adds 5–8 days for international delivery.

Can SP901E LED controller producers ship globally?

Yes, most established manufacturers support worldwide shipping via air or sea freight. Confirm FOB origin terms and ensure packaging meets ISTA 3A standards for electronic goods. Suppliers should provide HS codes and compliance documentation for smooth customs clearance.

Do manufacturers offer free samples?

Sample policies vary. Some suppliers waive fees for qualified buyers committing to minimum order quantities (typically ≥500 units). Otherwise, expect to cover 40–60% of unit cost plus shipping, refundable upon order confirmation.

How to request custom features on SP901E controllers?

Submit detailed specifications including voltage range (DC 5–24V), output channel count, PWM frequency requirements, and communication protocols (e.g., WiFi, Zigbee, DALI). Reputable producers will provide circuit diagrams, pinout layouts, and firmware logic within 72 hours, with prototypes ready in 3–4 weeks.