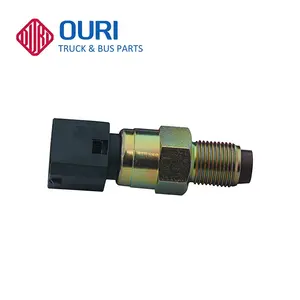

Speed Sensor

Top sponsor listing

Top sponsor listing

1/8

1/8

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/33

1/33

1/3

1/3

1/3

1/3

1/3

1/3

1/23

1/23

1/2

1/2

0

0

1/3

1/3

1/2

1/2

1/3

1/3

About speed sensor

Where to Find Speed Sensor Suppliers?

China remains a dominant force in the global automotive sensor manufacturing sector, with key production clusters concentrated in Guangdong and Henan provinces. Guangzhou and Shenzhen serve as high-tech hubs for electronic component fabrication, offering advanced surface-mount technology (SMT) lines and precision testing equipment essential for reliable speed sensor production. Zhengzhou, located in central China, has emerged as a logistics and industrial center supporting commercial vehicle and bus parts supply chains, enabling cost-efficient distribution across domestic and international markets.

These regional ecosystems provide suppliers with access to vertically integrated production networks—spanning PCB assembly, housing injection molding, calibration systems, and final testing—within compact geographic zones. This integration supports rapid prototyping, scalable batch production, and reduced lead times. Buyers benefit from localized sourcing of raw materials such as ABS plastic, stainless steel connectors, and Hall-effect or variable reluctance sensing elements, which contribute to 15–25% lower unit costs compared to Western alternatives. Average delivery cycles range from 7 to 20 days depending on order complexity and customization level.

How to Choose Speed Sensor Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Quality Management Systems

Prioritize suppliers with ISO/TS 16949 or ISO 9001 certification, indicating adherence to automotive-grade quality controls. While not all suppliers list formal certifications in public data, verified performance metrics such as on-time delivery rates above 95% and documented response protocols suggest robust internal processes. For applications involving ABS, transmission control, or tachograph integration, request evidence of EMI shielding, IP67-rated sealing, and temperature tolerance testing (-40°C to +125°C).

Production and Engineering Capacity

Assess supplier capability through observable indicators:

- Minimum monthly output capacity exceeding 10,000 units for standard models

- In-house tooling and mold-making capabilities for custom housings and connector designs

- Availability of OEM/ODM services including laser marking, color coding, and packaging configuration

Cross-reference product listings with reorder rates above 20% as a proxy for customer satisfaction and field reliability.

Transaction Reliability and Support

Favor suppliers demonstrating consistent communication (response time ≤3 hours) and transparent pricing structures. Analyze listed minimum order quantities (MOQs), which typically range from 1 to 10 pieces for sample validation and scale to bulk volumes. Confirm whether suppliers support third-party inspection services prior to shipment and offer technical documentation such as wiring diagrams, signal output specifications (e.g., square wave, sine wave), and compatibility matrices.

What Are the Best Speed Sensor Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Sample MOQ |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Super Technology Co., Ltd. | Guangdong, CN | Auto Sensors, Ignition Coils, Fuel Filters, Injection Valves | US $800,000+ | 99% | ≤3h | 20% | Color, material, size, logo, packaging, graphic | 1 piece |

| Guangzhou Brace Auto Parts Co., Ltd. | Guangdong, CN | ABS Sensors, Odometer Sensors, Car Speed Sensors | US $240,000+ | 94% | ≤5h | 30% | Color, material, size, logo, packaging, graphic | 1 piece |

| Zhengzhou Natong Auto Parts Co., Ltd. | Henan, CN | Bus & Truck Sensors, VDO-Compatible Units, Universal Speedometers | US $1,300,000+ | 88% | ≤2h | 21% | Limited customization per listing | 10 pieces |

| Ruian Zhengli Auto Parts Limited Company | Zhejiang, CN | Construction Machinery Sensors, Diesel Engine Units, Odometers | US $8,000+ | 92% | ≤4h | 16% | Not specified | 5–10 pieces |

| Shenzhen Ninghui Technology Limited | Guangdong, CN | GPS-Based Speed Detectors, Tachograph Sensors, Motorcycle Meters | US $410,000+ | 100% | ≤5h | <15% | Application-specific design flexibility | 2–4 pieces |

Performance Analysis

Guangzhou-based suppliers demonstrate strong customization capabilities and low sample MOQs, making them ideal for buyers evaluating fitment across diverse vehicle platforms. Zhengzhou Natong leads in revenue volume, reflecting extensive engagement in heavy-duty transport sectors, though its 88% on-time delivery rate warrants closer logistical scrutiny. Shenzhen Ninghui stands out with perfect delivery compliance but a sub-15% reorder rate, suggesting potential gaps in post-sale support or long-term reliability. Guangzhou Brace achieves a high 30% reorder rate, indicating strong end-user satisfaction despite moderate response speed. For mission-critical applications, prioritize suppliers with proven experience in OE-tier supply chains and those offering detailed technical datasheets for signal frequency, air gap tolerance, and connector pinouts.

FAQs

How to verify speed sensor supplier reliability?

Evaluate consistency in delivery performance (target ≥95%), responsiveness (<5 hours), and transparency in product specifications. Request sample units to validate build quality, shielding integrity, and output signal stability using oscilloscope testing. Verify traceability of core components such as IC chips and magnetic cores.

What is the typical sampling timeline?

Standard samples ship within 3–7 days after confirmation. Customized versions requiring new molds or firmware adjustments may require 15–25 days. Air freight adds 5–10 days for international delivery.

Do suppliers offer customization for OEM projects?

Yes, multiple suppliers list options for color, labeling, packaging, and physical dimensions. Confirm compatibility with existing ECUs and dashboard systems before finalizing design changes. Some manufacturers provide CAD drawings and simulation data upon request.

What are common MOQs and pricing ranges?

MOQs vary from 1 piece (for evaluation) to 1,000+ units for full-scale procurement. Unit prices range from $1–$5 for basic models to $20–$45 for GPS-integrated or industrial-grade sensors. Volume discounts are commonly available beyond 500 units.

Can speed sensors be integrated with GPS or telematics systems?

Certain suppliers, particularly Shenzhen Ninghui, specialize in hybrid detection systems combining wheel-speed inputs with GPS data for fleet monitoring and odometer calibration. Technical coordination is required to ensure synchronization between analog/digital signals and onboard processors.