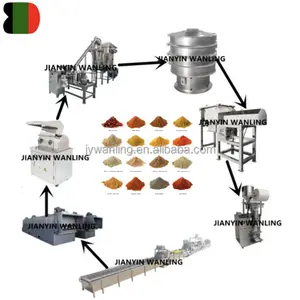

Spice Processing Machine

About spice processing machine

Where to Find Spice Processing Machine Suppliers?

China remains the central hub for spice processing machine manufacturing, with key production clusters in Henan and surrounding provinces. These regions host vertically integrated industrial ecosystems specializing in food-grade grinding, pulverizing, and milling equipment. Henan alone accounts for a significant share of China’s spice machinery output, supported by mature supply chains for stainless steel components, motor systems, and precision hammer mills. Proximity to raw material sources and logistics hubs enables efficient production scaling and export distribution.

The concentration of manufacturers in this region supports cost-effective production through localized sourcing of critical components such as 304 stainless steel chambers, water-cooled crushing systems, and variable-speed motors. This integration reduces lead times and allows suppliers to offer competitive pricing, with standard models starting below $600 per unit. Buyers benefit from access to both standardized units and engineered solutions tailored to specific throughput, fineness, or sanitation requirements. Average delivery timelines range from 15–30 days for in-stock configurations, with customization adding 7–14 days depending on complexity.

How to Choose Spice Processing Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Quality Assurance Standards

Verify adherence to international quality benchmarks. While formal ISO 9001 certification is not universally declared in available data, suppliers with high on-time delivery rates (≥99%) and strong online transaction volumes often maintain internal quality control systems. For food-contact applications, confirm use of food-grade materials (e.g., 304 stainless steel) and compliance with hygiene design principles. CE marking may be required for entry into European markets, though explicit documentation should be requested directly from the supplier.

Production and Technical Capacity

Assess infrastructure indicators where available:

- Facility scale inferred from product catalog breadth—suppliers listing 500+ related machines likely operate larger production lines

- In-house engineering capability, evidenced by customization options (motor power, mesh size, capacity, color, labeling)

- Use of advanced features such as water-cooled systems, noise reduction enclosures, and dust collection integration

Cross-reference response time (≤1 hour indicates dedicated sales and technical support teams) and reorder rates to gauge customer satisfaction and reliability.

Procurement Risk Mitigation

Utilize secure payment mechanisms and pre-shipment verification protocols. Prioritize suppliers offering sample units for performance testing under real operating conditions. Confirm packaging standards and export experience, especially for sensitive electrical components. Analyze historical transaction data—measured by online revenue and repeat order behavior—to assess financial stability and service consistency.

What Are the Best Spice Processing Machine Suppliers?

| Company Name | Location | Main Product Focus | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (Min. Order: 1 Set) | Notable Features |

|---|---|---|---|---|---|---|---|---|

| Luohe Xingdian Electromechanical Equipment Co., Ltd. | Henan, CN | Spice grinders, water-cooled hammer crushers | US $640,000+ | 99% | ≤1h | <15% | $550–$1,290 | Food-grade stainless steel, water-cooling technology |

| Henan Restar Machinery Co.,Ltd | Henan, CN | Fruit & vegetable processing, fine powder grinders | US $20,000+ | 100% | ≤4h | 33% | $1,286–$5,199 | Multi-functional designs, high-capacity models |

| Xinxiang Chenwei Machinery Co., Ltd. | Henan, CN | Industrial spice pulverizers, seasoning grinders | US $240,000+ | 100% | ≤2h | <15% | $820–$12,000 | Extensive customization: motor power, fineness, branding |

| Henan Panqi Heavy Industry Technology Co., Ltd. | Henan, CN | Wood crushers, plastic machinery, spice grinders | US $10,000+ | 90% | ≤1h | <15% | $610–$2,000 | Broad industrial equipment portfolio, entry-level pricing |

| Nanchang Kay Xin Yue Technologies Co., Ltd. | Jiangxi, CN | Oil pressers, snack machines, portable grinders | US $50,000+ | 75% | ≤8h | 15% | $89–$510 (per piece) | Low-cost, portable models; higher MOQs apply |

Performance Analysis

Luohe Xingdian stands out for high transaction volume and near-perfect delivery performance, offering competitively priced, food-safe equipment ideal for small to mid-scale processors. Henan Restar demonstrates strong customer retention (33% reorder rate), suggesting reliable post-sale support and consistent machine performance. Xinxiang Chenwei provides the widest customization scope, including motor specifications and labeling options, making it suitable for branded or private-label procurement. While Nanchang Kay Xin Yue offers the lowest price points, its 75% on-time delivery rate presents higher fulfillment risk, warranting additional due diligence. Buyers seeking industrial-grade systems should prioritize suppliers with documented use of 304 stainless steel, cooling mechanisms, and scalable output capacities.

FAQs

What are typical minimum order quantities (MOQs) for spice processing machines?

Most suppliers list a minimum order of 1 set, particularly for commercial or industrial models. Portable or consumer-grade units may require 2 pieces or more. No supplier imposes large-volume MOQs, facilitating pilot purchases and small business adoption.

How long does production and shipping take?

Standard units are typically dispatched within 15–20 days after order confirmation. Customized configurations may require an additional 7–14 days. International air freight takes 5–10 days; sea freight ranges from 20–40 days depending on destination port and customs procedures.

Can spice processing machines be customized?

Yes, select suppliers like Xinxiang Chenwei offer customization in motor power, grinding fineness (mesh size), color, logo printing, and packaging. Buyers should provide detailed technical parameters to ensure compatibility with intended applications.

Are samples available before bulk ordering?

Sample availability varies. Some suppliers allow single-unit purchases equivalent to sample testing. Pricing for samples reflects full production cost, with no universal policy for free trials. Confirm sample return policies and re-stocking fees if applicable.

What materials are used in construction?

High-end models utilize 304 stainless steel for contact surfaces to meet food safety standards. Hammer mills, screens, and grinding chambers in premium units are corrosion-resistant and designed for easy cleaning. Lower-cost models may incorporate coated carbon steel; buyers should verify material specifications prior to procurement.