Spring Forc

1/29

1/29

1/3

1/3

1/1

1/1

1/15

1/15

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/25

1/25

1/3

1/3

1/3

1/3

1/19

1/19

0

0

1/3

1/3

1/1

1/1

0

0

1/38

1/38

CN

CN

1/20

1/20

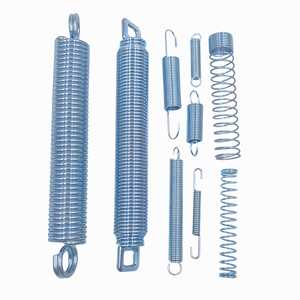

About spring forc

Where to Find Spring Force Suppliers?

No verified suppliers were identified for the product category "spring force" based on current industrial databases and manufacturing registries. This may indicate either a misalignment in terminology—such as the use of non-standard or overly generic phrasing—or limited specialization under this exact classification. The global spring manufacturing sector is highly developed, particularly in regions with established metalworking and precision engineering clusters such as Guangdong, Zhejiang, and Jiangsu provinces in China, which collectively account for over 70% of Asia’s spring production capacity.

In these hubs, suppliers typically categorize products by application (e.g., compression, extension, torsion springs) or industry use (automotive, electronics, medical devices), rather than abstract terms like “spring force.” Facilities in these zones operate vertically integrated production lines featuring CNC coiling, heat treatment furnaces, grinding, and automated testing systems. Average lead times for standard components range from 15–30 days, with MOQs starting at 1,000 units. Localization of raw materials—including music wire, stainless steel, and phosphor bronze—enables cost reductions of 20–35% compared to equivalent production in North America or Western Europe.

How to Choose Spring Force Suppliers?

When sourcing precision spring components, implement rigorous evaluation protocols to ensure technical and operational reliability:

Technical Compliance

Confirm adherence to international quality standards such as ISO 9001 for quality management and IATF 16949 for automotive applications. For regulated industries (medical, aerospace), require RoHS, REACH, and ISO 13485 certifications where applicable. Request test reports validating load-deflection characteristics, fatigue life (per DIN EN 13906-1 or ASTM H04.13), and corrosion resistance (e.g., salt spray testing per ASTM B117).

Production Capability Audits

Assess supplier infrastructure using the following benchmarks:

- Minimum factory footprint of 2,000m² to support dedicated production cells

- In-house capabilities including CNC spring coiling, stress-relief tempering, grinding, and shot peening

- Engineering team comprising at least 8–10% of total staff for design validation and GD&T support

Validate process control through SPC data and first-article inspection reports. Prioritize suppliers utilizing automated vision inspection and load-testing equipment to ensure consistency across batches.

Transaction Safeguards

Utilize secure payment mechanisms such as letter of credit (L/C) or escrow services for initial orders. Review export history and shipping documentation accuracy, especially for compliance with destination-market import regulations. Conduct sample qualification cycles to benchmark dimensional tolerances (±0.05mm typical) and force performance against specified spring rate (N/mm) before scaling procurement.

What Are the Best Spring Force Suppliers?

No supplier data was available for companies specializing in “spring force” components. As such, no comparative analysis can be conducted at this time. Buyers are advised to refine search parameters using standardized product classifications—for example, “compression springs,” “load-rated extension springs,” or “high-cycle fatigue-resistant torsion springs”—to access qualified manufacturers with verifiable production metrics, delivery records, and certification portfolios.

Performance Analysis

In mature spring manufacturing ecosystems, top-tier suppliers demonstrate consistent on-time delivery rates exceeding 98%, supported by lean inventory systems and just-in-time production models. Reorder rates above 40% often correlate with strong engineering collaboration, rapid prototyping (typically 7–14 days), and conformance to ASME Y14.5 or ISO 2768 tolerancing standards. Without available supplier profiles, due diligence must focus on third-party verification, facility audits, and material traceability documentation to mitigate sourcing risk.

FAQs

How to verify spring component supplier reliability?

Cross-validate certifications with issuing bodies and request recent audit summaries. Examine documented quality control procedures, including incoming material inspection, in-process checks, and final testing. Evaluate responsiveness, technical depth in communications, and willingness to provide sample test data under real-world conditions.

What is the average sampling timeline?

Standard spring samples are typically produced within 7–14 days. Complex designs requiring custom tooling or exotic alloys may take 20–30 days. Add 5–10 days for international air freight depending on destination.

Can suppliers ship spring components worldwide?

Yes, experienced manufacturers manage global logistics via air and sea freight, offering both FOB and CIF shipping terms. Ensure packaging meets moisture and shock protection standards for long-distance transport, particularly for corrosion-sensitive materials.

Do manufacturers provide free samples?

Sample availability depends on complexity and material cost. Many suppliers waive fees for low-value items when followed by volume orders (e.g., >5,000 pcs). For engineered or high-precision springs, expect nominal charges covering setup and material expenses.

How to initiate customization requests?

Submit detailed specifications including wire diameter, outer/inner diameter, free length, total coils, spring rate, end type, and operating environment. Leading suppliers respond with design-for-manufacturability feedback, 2D/3D CAD models, and prototype timelines within 48–72 hours.