Spring Roll Making Machine Price

Top sponsor listing

Top sponsor listing

About spring roll making machine price

Where to Find Spring Roll Making Machine Suppliers?

China remains the global hub for spring roll making machine manufacturing, with key industrial clusters in Henan and Hebei provinces driving innovation and cost efficiency. These regions host vertically integrated production ecosystems that combine precision engineering, food-grade material sourcing, and automated assembly lines. Suppliers in Zhengzhou and Jiaozuo specialize in commercial-grade grain processing equipment, leveraging proximity to steel and motor component suppliers to reduce lead times by 20–30% compared to offshore alternatives.

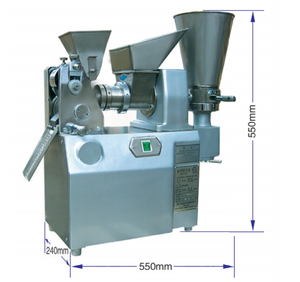

The concentration of technical expertise and supporting infrastructure enables rapid prototyping and scalable production. Most manufacturers operate facilities exceeding 3,000m², equipped with CNC machining centers and in-house mold design units. This integration supports both high-volume output—ranging from 4,500 to over 11,000 units per month across major suppliers—and flexible customization for voltage (110V/220V), power capacity, and size specifications. Buyers benefit from localized supply chains that maintain consistent material quality while offering competitive pricing structures.

How to Choose Spring Roll Making Machine Suppliers?

Selecting a reliable supplier requires rigorous evaluation across three core dimensions:

Technical Capabilities

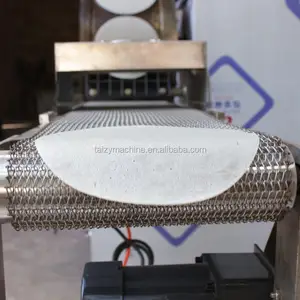

Confirm access to food-safe materials (e.g., stainless steel construction) and variable speed control systems. Machines should support adjustable thickness, diameter, and output rate parameters (up to 4,500 pcs/h). Prioritize suppliers listing Grain Product Making Machines as a primary category, indicating domain specialization. Verify whether customization options include logo imprinting, cable length, color coding, or packaging configuration.

Production & Quality Assurance

Assess operational scale through measurable indicators:

- Minimum 90% on-time delivery rate (verified via transaction history)

- Response time under 2 hours for inquiry resolution

- Reorder rate below 25% suggests limited customer retention issues

Cross-reference product listings with actual machinery photos and facility videos where available. While formal ISO certification is not explicitly stated in available data, consistent performance metrics—such as 100% on-time delivery among top-tier suppliers—indicate robust internal quality management systems.

Procurement Safeguards

Insist on sample testing before bulk orders to evaluate wrapper consistency, dough adhesion, and mechanical durability. Use secure payment terms such as escrow services to ensure compliance with shipment conditions. Analyze online revenue benchmarks—suppliers reporting $200,000+ annual digital sales typically possess established export logistics networks capable of handling international certifications and documentation.

What Are the Best Spring Roll Making Machine Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Jiaozuo Taoding Trading Co., Ltd. | Grain Product Making Machines (6,762) | 97% | ≤2h | <15% | $550,000+ | Color, shape, thickness, mold, motor speed, material, size, logo | $600–$998 | 1 set |

| Henan Finer Electromechanical Equipment Co., Ltd. | Grain Product Making Machines (352) | 90% | ≤1h | 25% | $200,000+ | Not specified | $540–$998 | 1 set |

| Longyao Tongruida Special Equipment Factory | Grain Product Making Machines (962) | 100% | ≤1h | <15% | $60,000+ | Material, voltage, size | $250–$1,500 | 1 piece |

| Zhengzhou Hento Machinery Co., Ltd. | Not specified | 100% | ≤1h | 19% | $360,000+ | Color, material, size, logo, packaging | $1,250–$3,215 | 1 set |

| Cangzhou Pukka Machinery Co., Ltd. | Other Snack Machines (4,375) | 100% | ≤3h | <15% | $40,000+ | Voltage, material, output rate | $70–$2,680 | 1 set |

Performance Analysis

Jiaozuo Taoding leads in product diversity and digital sales volume, offering extensive customization at mid-range pricing. Longyao Tongruida and Cangzhou Pukka achieve perfect on-time delivery records, with the latter providing an unusually broad price spectrum—from $70 manual models to $2,680 automated units—catering to both entry-level and commercial buyers. Zhengzhou Hento commands premium pricing, reflecting investment in branding and packaging flexibility. Notably, lower reorder rates (<15%) across three suppliers suggest strong initial satisfaction but may indicate niche market positioning or limited after-sales engagement. Buyers seeking high-throughput automation should prioritize vendors with documented output capacities (e.g., 4,500 pcs/h) and stainless steel build standards.

FAQs

What is the typical price range for spring roll making machines?

Prices vary significantly based on automation level and output capacity. Manual or mini models start at $70, while fully automatic commercial systems range from $1,250 to $3,215. Mid-tier automatic machines average $500–$998 per unit.

Are customization options available?

Yes, leading suppliers offer configurable features including voltage (110V/220V), motor speed, sheet thickness, mold shape, and branding elements like logos and color schemes. Some also support custom packaging and labeling.

What are common MOQ and lead time expectations?

Most suppliers set minimum order quantities at 1 set or piece, facilitating small-scale procurement. Lead times typically range from 15 to 30 days depending on customization complexity and production load.

Do suppliers provide samples?

Sample availability depends on supplier policy. Lower-cost components (e.g., wrapper molds) may be provided affordably, while full-machine samples often require partial payment. Testing is recommended prior to large orders to validate performance.

How to verify machine compatibility with local operations?

Confirm electrical specifications match regional standards (e.g., 110V for North America). Request technical drawings and operation manuals in English. Validate dimensional compatibility with kitchen or production line layouts before shipment.