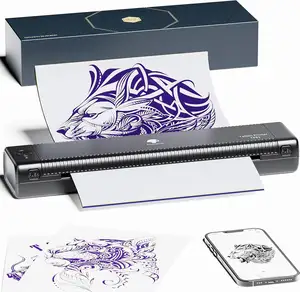

Stencil Label Maker

About stencil label maker

Where to Find Stencil Label Maker Suppliers?

China remains the central hub for stencil label maker production, with key manufacturing clusters concentrated in Fujian and Guangdong provinces. Xiamen and Shenzhen serve as primary industrial centers, hosting vertically integrated facilities that specialize in thermal printing technology and portable labeling equipment. These regions benefit from mature electronics supply chains, enabling rapid component sourcing for printheads, batteries, and control modules.

The ecosystem supports both high-volume OEM/ODM production and low-MOQ customized orders, driven by agile manufacturing lines capable of switching between product configurations within 48 hours. Average lead times range from 15–25 days for standard models, with express assembly options available for urgent procurement. Localization reduces material costs by 18–25% compared to non-Asian manufacturers, particularly for plastic housings, thermal paper rolls, and Bluetooth-enabled circuitry.

How to Choose Stencil Label Maker Suppliers?

Procurement decisions should be guided by structured evaluation criteria focused on technical reliability, production transparency, and transactional security.

Quality Assurance Verification

Confirm adherence to international quality standards such as ISO 9001. While not universally declared in supplier profiles, compliance is typically reflected in on-time delivery rates exceeding 95%. For buyers targeting EU or North American markets, verify RoHS and CE conformity for electronic components to ensure regulatory clearance.

Production Capacity Assessment

Evaluate operational scale through measurable indicators:

- Minimum monthly output capacity of 10,000 units for stable inventory fulfillment

- In-house design and firmware development teams supporting customization

- Integration of digital printing, embossing, and wireless connectivity (Bluetooth) across product lines

Cross-reference online revenue data (where disclosed) with reorder rates; suppliers reporting US $200,000+ annual digital sales generally maintain robust logistics and QC systems.

Customization & Transaction Safeguards

Prioritize suppliers offering documented customization options—including logo imprinting, packaging modification, language interface selection, and material specification (e.g., PET, PVC, biodegradable substrates). Use secure payment mechanisms such as trade assurance programs to mitigate risk. Request physical or digital samples before bulk ordering to validate print clarity, adhesive performance, and device ergonomics.

What Are the Best Stencil Label Maker Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | MOQ Range | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Mertouch Technology Co., Limited | Guangdong, CN | Multispecialty Supplier | US $260,000+ | 95% | ≤8h | <15% | 1–2 pieces | $6.50–123 |

| Xiamen Aiyin Technology Co., Ltd. | Fujian, CN | - | US $170,000+ | 98% | ≤2h | <15% | 10–500 pieces | $29–69 |

| Taizhou Pairsun Printing Co., Ltd. | Zhejiang, CN | Custom Manufacturer | US $250,000+ | 95% | ≤2h | 21% | 10,000–30,000 pieces | $0.005–0.05 |

| Xiamen Spring Import & Export Co., Ltd. | Fujian, CN | - | US $230,000+ | 100% | ≤2h | 15% | 1 piece | $26–72 |

| Xiamen Diaodiao Technology Co., Ltd. | Fujian, CN | Multispecialty Supplier | US $20,000+ | 100% | ≤1h | <15% | 1 piece/set/box | $11–45.57 |

Performance Analysis

Suppliers based in Xiamen demonstrate superior responsiveness, with three out of five achieving average reply times under 2 hours—critical for time-sensitive negotiations. Xiamen Spring Import & Export and Xiamen Diaodiao Technology report perfect 100% on-time delivery records, indicating strong internal logistics coordination despite moderate reorder rates. Shenzhen-based Mertouch offers the widest product range and highest reported revenue, suggesting scalability for large-volume buyers.

Taizhou Pairsun stands out for ultra-low-cost sticker label production but requires minimum orders of 10,000 units, making it suitable only for mass distribution channels. In contrast, multiple Fujian and Guangdong suppliers support single-unit MOQs, ideal for testing market fit or integrating into niche applications like tattoo studios or warehouse logistics.

FAQs

How to verify stencil label maker supplier reliability?

Validate claims through third-party transaction platforms showing verifiable order history, customer feedback, and dispute resolution outcomes. Request factory audit reports or video walkthroughs of production lines. Confirm consistency between listed capabilities (e.g., Bluetooth integration, embossing) and actual product specifications.

What is the typical sampling timeline?

Standard sample processing takes 5–10 business days, depending on customization level. Wireless or embossed label makers may require up to 15 days due to firmware configuration. Air shipping adds 7–12 days globally. Some suppliers offer free samples contingent upon future bulk commitments.

Can suppliers accommodate custom branding and packaging?

Yes, most suppliers listed provide full customization services—including logo printing, color variation, user manual localization, and private-labeled packaging. Minimum thresholds vary: electronics-focused suppliers accept changes at 100–500 units, while sticker producers require 10,000+ units for mold/tooling adjustments.

What materials are commonly used in stencil label makers?

Devices use ABS plastic casings with thermal print heads; labels are typically produced on PET, PVC, or biodegradable roll stock. Adhesive properties, tear resistance, and compatibility with skin (for tattoo stencils) or industrial surfaces (for asset tagging) must be specified during procurement.

Are there differences between thermal and mechanical label makers?

Thermal models dominate this segment, utilizing heat-sensitive paper without ink cartridges—ideal for portable use. They support barcode generation, mobile app connectivity, and variable text input. Mechanical embossing units create raised text for durable identification but lack wireless functionality. Buyers should align technology choice with end-use environment: thermal for dynamic labeling, embossed for long-term asset tracking.