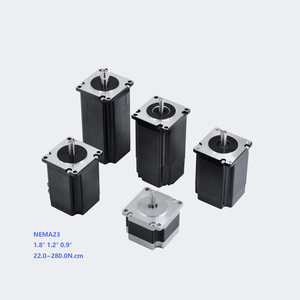

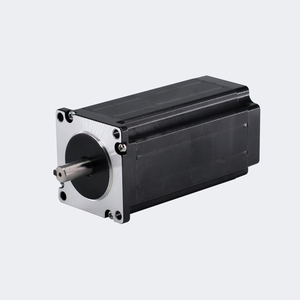

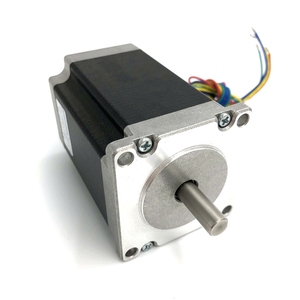

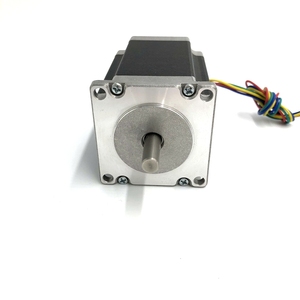

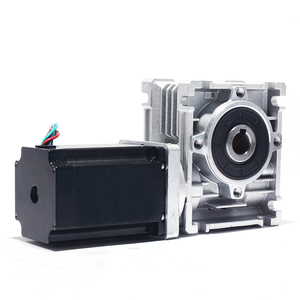

Stepper Motor Nema 23

Top sponsor listing

Top sponsor listing

1/3

1/3

1/11

1/11

1/18

1/18

1/26

1/26

1/27

1/27

1/44

1/44

1/3

1/3

1/3

1/3

1/38

1/38

1/23

1/23

1/3

1/3

1/3

1/3

1/23

1/23

1/3

1/3

1/3

1/3

0

0

1/3

1/3

About stepper motor nema 23

Where to Find Stepper Motor NEMA 23 Suppliers?

China remains the central hub for stepper motor manufacturing, with key suppliers concentrated in industrial zones of Changzhou and Guangzhou. These regions host specialized electromechanical clusters integrating precision machining, coil winding, and magnetic assembly lines, enabling high-volume production of hybrid and closed-loop NEMA 23 stepper motors. Changzhou, in particular, has evolved into a core node for motion control components, supported by localized supply chains for laminations, bearings, and encoder systems.

The ecosystem supports rapid prototyping and scalable production, with many facilities operating automated winding and balancing equipment to maintain consistent torque output. Suppliers in this region typically offer lead times of 15–30 days for standard models and 30–45 days for customized configurations. Localized sourcing of raw materials—such as silicon steel, copper wire, and neodymium magnets—reduces material costs by 18–25% compared to non-specialized manufacturing bases. Buyers benefit from proximity to component vendors, reducing logistics complexity and enabling faster iteration cycles for OEM integration.

How to Choose Stepper Motor NEMA 23 Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Customization Capability

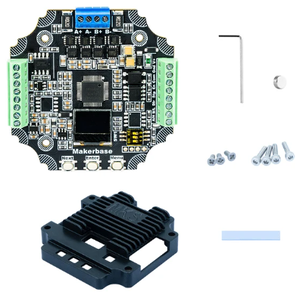

Verify that suppliers support essential customization parameters including shaft diameter (4–8mm common), holding torque (0.5–3.0 N·m range), voltage (12–48V DC), and wiring configurations (4, 6, or 8 leads). Advanced providers offer integrated solutions such as planetary gearboxes, lead screws, encoders, and CANopen control interfaces. Confirm availability of CAD drawings, pulse signal compatibility, and thermal protection features for demanding automation environments.

Production & Quality Assurance

Assess supplier infrastructure through verifiable indicators:

- In-house production lines for stator winding, rotor magnetization, and dynamic balancing

- Testing protocols for insulation resistance (>100 MΩ), dielectric strength (AC 500V/1 min), and temperature rise under full load

- Compliance with international standards such as CE, RoHS, and ISO 9001 (where documented)

- On-time delivery performance exceeding 99% and response times under 3 hours

Cross-reference product listings with actual testing reports and seek evidence of lifetime torque stability and repeatability in open- or closed-loop operation.

Procurement & Risk Mitigation

Utilize structured sampling procedures: request physical or digital samples with detailed electrical specifications before scaling orders. Prioritize suppliers offering third-party transaction protection and clear dispute resolution mechanisms. Evaluate reorder rates as a proxy for customer satisfaction—rates above 20% indicate consistent quality and service reliability. MOQs vary widely, from 1 set (for premium models) to 50–100 sets for bulk pricing, allowing flexibility for both prototyping and volume deployment.

What Are the Best Stepper Motor NEMA 23 Suppliers?

| Company Name | Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Changzhou Jkongmotor Co., Ltd. | Custom Manufacturer | Stepper Motors, DC Motors, Motor Drivers | US $340,000+ | 100% | ≤3h | 20% | Torque, control type, gearbox, wire length, servo integration |

| Spotlight Universe (Changzhou) Co., Ltd. | Not Specified | Stepper Motors, DC Motors, AC Motors, Speed Reducers | US $2,000+ | 100% | ≤2h | 50% | Limited (product-level variants) |

| Changzhou Maples Precision Electromechanical Co., Ltd. | Multispecialty Supplier | Stepper Motors, Hybrid Servo Motors | US $230,000+ | 100% | ≤2h | 19% | Brake, cable length, color, logo, packaging |

| Guangzhou Hanpose 3D Technology Co., Ltd. | Custom Manufacturer | CNC Kits, Stepper Motors, Motor Drivers | US $260,000+ | 99% | ≤2h | 16% | Shaft diameter, color, engraving, waterproofing, gearbox |

| Chongqing Umot Technology Co., Ltd. | Custom Manufacturer | NEMA 17/23/34 Stepper Motors, DC Motors | US $260,000+ | 100% | ≤1h | 20% | Color, size, logo, packaging, labeling |

Performance Analysis

Changzhou-based manufacturers dominate responsiveness and technical breadth, with three suppliers achieving sub-2-hour average reply times. Spotlight Universe stands out with a 50% reorder rate—the highest in the dataset—indicating strong post-sale satisfaction despite lower reported online revenue. Chongqing Umot Technology leads in communication efficiency (≤1h response) and offers broad NEMA platform compatibility, making it suitable for multi-motor automation projects. Changzhou Jkongmotor provides the most extensive engineering customization, including CANopen and trapezoidal screw integrations, ideal for advanced motion control applications. While Guangzhou Hanpose focuses on CNC kits, its deep customization in mechanical specs supports niche industrial builds.

FAQs

How to verify stepper motor NEMA 23 supplier reliability?

Confirm compliance with CE and RoHS standards through documentation. Request test reports for insulation class, step angle accuracy (±5% typical), and pull-out torque curves. Analyze supplier transaction history, focusing on on-time delivery consistency and customer feedback related to motor longevity and thermal performance.

What is the typical MOQ and pricing range?

MOQs range from 1 set (common for closed-loop or EU-stocked units) to 100 sets for entry-level models. Pricing varies significantly by configuration: basic hybrid motors start at $7–$12/set, while high-torque or closed-loop versions with encoders reach $30–$110/set. Volume discounts are typically available beyond 500 units.

Can suppliers provide custom shafts or connectors?

Yes, multiple suppliers support shaft customization (diameter, length, threading) and connector types (JST, AMP, bare leads). Some offer IP-rated housings, brakes, and mounting flanges. Technical drawings and specifications must be submitted prior to production to ensure compatibility.

Do suppliers offer global shipping and export support?

All listed suppliers have international transaction experience and support FOB and CIF shipping terms. Most provide export documentation and can accommodate air or sea freight based on order size. Lead times include 5–10 days for customs clearance and final delivery.

How to initiate a customization request?

Submit detailed technical requirements including desired holding torque, current rating, step angle (1.8° or 0.9°), shaft specifications, and environmental conditions. Reputable suppliers will respond within 24 hours with feasibility assessment, sample timelines (typically 10–20 days), and prototype quotes.