Stick Making Machine Producer

0

0

0

0

1/2

1/2

1/3

1/3

1/3

1/3

1/3

1/3

1/25

1/25

1/23

1/23

1/10

1/10

1/8

1/8

1/22

1/22

1/3

1/3

0

0

1/3

1/3

1/14

1/14

1/17

1/17

1/9

1/9

1/3

1/3

1/3

1/3

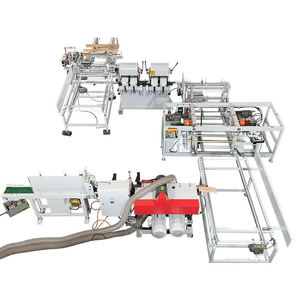

About stick making machine producer

Where to Find Stick Making Machine Producers?

Global production of stick making machines is concentrated in specialized industrial hubs across China and India, where vertically integrated manufacturing ecosystems support diverse applications—from food processing to woodworking. Chinese suppliers dominate high-capacity automated systems for wafer sticks, bread sticks, and rice noodles, leveraging advanced CNC machining and extrusion technologies. Indian manufacturers, particularly in Maharashtra and Gujarat, focus on cost-efficient bamboo stick and broom-making machinery using localized raw material access and modular design principles.

These regions offer distinct competitive advantages: Chinese producers benefit from mature supply chains in Shanghai and Tianjin, enabling rapid assembly of servo-driven, full-automatic lines with integrated quality control systems. Indian workshops emphasize compact, energy-efficient models suited for small-to-medium enterprises, often incorporating adjustable dies and multi-profile tooling. Buyers gain access to scalable solutions ranging from $645 benchtop units to $250,000 turnkey production lines, with lead times typically between 30–60 days depending on automation level and customization scope.

How to Choose Stick Making Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Application Fit

Verify machine compatibility with target output—whether edible sticks (wafer, bread, rice noodle) or non-food items (bamboo, popsicle). Demand detailed process flow documentation, including extrusion pressure, forming speed (units per minute), and temperature control ranges. For food-grade equipment, confirm compliance with FDA or EU 1935/2004 standards for contact materials. Non-food machinery should demonstrate durability under continuous operation, with hardened steel components and wear-resistant coatings.

Production Capacity and Infrastructure

Assess physical capabilities through verifiable metrics:

- Minimum factory area exceeding 3,000m² for industrial-scale output

- In-house engineering teams capable of custom die design and PLC programming

- Proven track record in delivering turnkey lines (mixing → extrusion → drying → cutting)

- Cross-reference online product catalogs with order fulfillment history, prioritizing suppliers with documented on-time delivery rates above 97%

Quality Assurance and Transaction Security

Require ISO 9001 certification as a baseline for quality management. For export markets, CE marking indicates adherence to European safety directives. Utilize secure payment mechanisms such as escrow services, especially for first-time transactions. Request sample batches to validate dimensional consistency, structural integrity, and surface finish before scaling procurement.

What Are the Leading Stick Making Machine Producers?

| Company Name | Specialization | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Main Product Lines |

|---|---|---|---|---|---|---|---|

| Shanghai Zhenghua Confectionery Machine Co., Ltd. | Wafer & confectionery sticks | $27,000–$46,000 | 1 set | 100% | ≤5h | - | Full-automatic wafer stick machines, multi-head egg roll lines |

| PRASHANT BAMBOO MACHINES PVT LTD | Bamboo stick & broom manufacturing | $645–$3,285 | 1 unit/piece | - | ≤3h | - | Square/round bamboo stick makers, customizable broom shaft machines |

| Saint Ngong Tat Machinery (Tianjin) Co., Ltd. | Rice flour & extruded food sticks | $100,000–$350,000 | 1 set | - | ≤15h | 100% | Automatic rice noodle extrusion lines, industrial stick-type snack systems |

| Snowball Machinery Tech Co., Ltd. | Popsicle & ice cream sticks | $40,000–$240,000 | 1 set | 100% | ≤16h | - | Ice cream stick forming lines, automatic popsicle production systems |

| Shanghai Seny Machinery Co., Ltd. | Bread & filled snack sticks | $8,400–$14,080 | 1 set | 100% | ≤2h | <15% | Fully automatic bread stick machines, multifunctional toast and baguette lines |

Performance Analysis

Shanghai-based producers lead in responsiveness and delivery reliability, with two suppliers achieving 100% on-time performance and sub-5-hour average response times. Snowball Machinery and Shanghai Zhenghua demonstrate strong integration of automation in food-grade environments, offering hygienic designs compliant with international food safety norms. Saint Ngong Tat stands out for customer retention, reflected in a verified 100% reorder rate despite higher price points, indicating consistent quality in large-scale rice noodle systems. PRASHANT BAMBOO MACHINES offers the lowest entry barrier with sub-$1,000 units ideal for startups, though lacks public delivery metrics. For high-volume buyers, prioritize suppliers with in-house R&D and stainless steel fabrication capacity to ensure long-term serviceability and spare parts availability.

FAQs

How to verify stick making machine producer credibility?

Validate certifications (ISO 9001, CE) through official registries. Request facility walkthrough videos highlighting CNC machining centers, testing stations, and final assembly lines. Analyze historical transaction data, focusing on consistent order patterns and customer feedback related to after-sales support and uptime performance.

What is the typical lead time for stick making machines?

Standard configurations ship within 30–45 days after deposit confirmation. Fully customized systems, especially those requiring new molds or PLC logic adjustments, require 50–70 days. Expedited builds may reduce timelines by 10–15 days at additional cost.

Can suppliers accommodate OEM or private labeling?

Yes, most established manufacturers support OEM branding on control panels, machine housings, and packaging. Minimum order thresholds vary—typically one full set for standard models. Technical documentation can be translated into English, Spanish, or Arabic upon request.

Are samples available before bulk purchase?

Sample availability depends on machine type. For high-value production lines, suppliers provide test-run videos and material samples produced on-site. Physical machine trials are possible under consignment terms, with costs applied toward full orders. Small-format machines may be shipped as demo units with freight collect.

What customization options are commonly offered?

Suppliers routinely modify mold cavities, conveyor speeds, voltage specifications (380V/50Hz vs. 220V/60Hz), and automation levels (semi-auto vs. fully integrated). Customizations must be specified early in the design phase, with engineering approval required for structural changes affecting load distribution or safety interlocks.