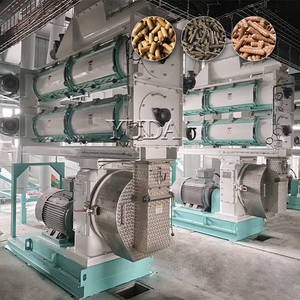

Stock Feed Making Machine Producer

1/15

1/15

1/21

1/21

1/25

1/25

1/31

1/31

1/20

1/20

1/10

1/10

About stock feed making machine producer

Where to Find Stock Feed Making Machine Producers?

China remains the global hub for stock feed making machine manufacturing, with key industrial clusters concentrated in Henan and Shandong provinces. These regions host vertically integrated supply chains encompassing die steel sourcing, precision machining, and final assembly, enabling cost efficiencies of 20–35% compared to Western counterparts. Henan, in particular, accounts for over half of China’s feed processing equipment suppliers, supported by mature logistics networks centered around Zhengzhou that facilitate rapid domestic and international dispatch.

The region’s ecosystem includes component manufacturers, automation specialists, and packaging system integrators operating within close proximity—reducing lead times and enhancing coordination. This clustering supports scalable production, with standard order fulfillment typically achieved within 25–40 days. Buyers benefit from flexible output capacities ranging from small-scale 50kg/h units to fully automated 2-ton/h production lines, catering to both emerging farms and commercial feed mills.

How to Choose Stock Feed Making Machine Suppliers?

Selecting reliable producers requires systematic evaluation across technical, operational, and transactional dimensions:

Quality Assurance & Compliance

Prioritize suppliers with documented adherence to ISO 9001 quality management standards. For export markets, confirm CE marking or equivalent regulatory compliance to ensure safety and customs clearance. Request test reports on critical parameters such as pellet density (target: 600–700 kg/m³), moisture resistance, and motor insulation class (typically IP54 or higher).

Production Capacity Verification

Assess infrastructure indicators to determine scalability:

- Minimum factory area of 3,000m² for consistent batch production

- In-house granulation, crushing, and mixing capabilities

- Integration of CNC machining and automated welding stations

Cross-reference claimed output rates (e.g., 200–5,000 kg/h) with verified online revenue data and delivery performance metrics.

Customization & Technical Support

Confirm availability of engineering support for tailored configurations—including die size (4–12mm), power source (electric/diesel), and auxiliary systems (steam conditioning, oil spraying, or color dosing). Leading suppliers offer CAD-based design validation and material flow simulations prior to production.

Transaction Security

Utilize secure payment mechanisms such as escrow services until post-arrival inspection is completed. Favor suppliers with transparent reorder rates and sub-3-hour response times, which correlate strongly with after-sales responsiveness. Always request physical or digital samples to validate build quality and pellet consistency before full-scale procurement.

What Are the Top Stock Feed Making Machine Producers?

| Company Name | Location | Main Products | Output Range | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Customization |

|---|---|---|---|---|---|---|---|---|

| Xuchang Jinglai Machinery Co., Ltd. | Henan, CN | Feed Processing Machines, Electric Forklifts | 200–1,000 kg/h | 100% | ≤3h | US $90,000+ | <15% | No |

| Weihui Haihua Machinery Co., Ltd. | Henan, CN | Feed Processing Machines, Silos, Mixing Equipment | 500–1,000 kg/h | 100% | ≤2h | US $2,000+ | – | No |

| Henan Coban Technology Co., Ltd. | Henan, CN | Animal Feed Lines, Crushers, Packaging Systems | 1–2 ton/h | 100% | ≤2h | US $110,000+ | 66% | Yes |

| Liyang Hongyang Feed Machinery Co., Ltd | Jiangsu, CN | Cow, Poultry, Livestock Feed Mills | 75–150 kg/h (up to 15,000 kg/h) | 92% | ≤1h | US $130,000+ | 27% | Yes |

| Baichuan (Zhengzhou) Intelligent Equipment Manufacturing Co., Ltd. | Henan, CN | Feed Processors, Wood Pellet Mills, Packaging Machines | Various (up to 18,888 USD models) | 100% | ≤1h | US $40,000+ | 28% | Yes |

Performance Analysis

Henan-based manufacturers dominate the market, combining high on-time delivery rates (all at or above 92%) with responsive communication. Henan Coban Technology stands out with a 66% reorder rate—indicating strong customer satisfaction—supported by comprehensive customization options including silo integration and steam supply systems. Liyang Hongyang demonstrates robust production flexibility, offering machines from entry-level 75kg/h models to large-scale $15,000+ systems, though its 92% on-time delivery suggests potential logistical constraints under peak demand. Baichuan and Xuchang Jinglai achieve perfect punctuality records with sub-3-hour response times, ideal for time-sensitive procurements. Suppliers with customization capabilities typically require 10–18 days for prototype development and provide technical drawings upon request.

FAQs

How to verify a stock feed making machine producer’s reliability?

Cross-validate certifications (ISO, CE) through issuing bodies and request facility audit reports. Analyze verifiable transaction histories, focusing on consistent on-time delivery (>95%), response efficiency (≤2h), and post-sale service responsiveness. Third-party inspection services can conduct pre-shipment quality checks.

What is the typical minimum order quantity (MOQ)?

Most suppliers set MOQ at 1 set for standard models. Some high-capacity production lines may require 2 sets. Bulk orders often unlock tiered pricing and extended warranty terms.

Do suppliers offer customization options?

Yes, select manufacturers provide OEM/ODM services including logo printing, voltage adjustments (380V/50Hz vs. 220V/60Hz), material finish (stainless vs. carbon steel), and integrated control panels. Custom dies, feeding systems, and automation modules are available upon technical specification submission.

What are common lead times for stock feed machines?

Standard units ship within 15–25 days after order confirmation. Customized or high-capacity production lines may take 30–45 days. Air freight delivers samples in 7–10 days; sea freight averages 20–35 days depending on destination port.

Can producers handle global shipping?

Yes, established exporters manage FOB, CIF, and DDP shipping terms. They prepare all necessary documentation (packing lists, certificates of origin, bill of lading) and comply with import regulations in North America, Europe, Africa, and Southeast Asia. Sea freight is recommended for full-container loads due to cost efficiency.