Stratasys Dmls

1/25

1/25

1/20

1/20

1/21

1/21

1/21

1/21

1/25

1/25

1/10

1/10

About stratasys dmls

Where to Find Stratasys DMLS Supplier Capabilities?

China remains a central hub for industrial additive manufacturing, with key supplier clusters in Guangzhou, Shenzhen, and Chengdu offering specialized expertise in metal 3D printing technologies, including Direct Metal Laser Sintering (DMLS). These regions host vertically integrated facilities that combine R&D, precision engineering, and rapid prototyping services, enabling scalable production of high-performance components. Guangzhou and Shenzhen are particularly notable for advanced laser melting systems, supported by mature supply chains for optical components, inert gas systems, and powder metallurgy materials.

Suppliers in these zones operate within ecosystems optimized for industrial 3D printing hardware and on-demand manufacturing services. Many offer end-to-end solutions—from machine fabrication to post-processing treatments such as heat treatment, sandblasting, and metrology validation. This integration supports lead times averaging 30–45 days for standard equipment orders, with service-based prototyping deliverables often fulfilled within 5–10 business days. Cost efficiencies stem from localized sourcing of critical subsystems, reducing unit pricing by 20–35% compared to OEM alternatives while maintaining compatibility with Stratasys-grade workflows and material specifications.

How to Evaluate Stratasys DMLS Suppliers?

Procurement decisions should be guided by structured technical and operational assessments:

Technical Capability Verification

Confirm suppliers possess documented experience with DMLS/SLM platforms, including laser power output (≥500W), build volume capacity (up to 450 × 450 × 450 mm³), and multi-laser configurations. Request validation of layer resolution (typically 20–50 µm) and support for aerospace- and medical-grade alloys (e.g., Ti6Al4V, Inconel 718, AlSi10Mg). For service providers, verify use of calibrated machines with environmental controls for oxygen levels (<100 ppm).

Production Infrastructure Audit

Assess core operational indicators:

- Minimum factory area exceeding 3,000m² for dedicated metal printing lines

- In-house capabilities covering CNC support removal, HIP processing, and CMM inspection

- Demonstrated R&D investment, indicated by patent portfolios or custom machine development

Cross-reference response times (target ≤5 hours) and on-time delivery rates (benchmark ≥96%) as proxies for operational reliability.

Transaction and Quality Assurance

Prioritize partners providing third-party quality documentation, including first-article inspections and material traceability reports. Utilize secure payment frameworks where milestones align with equipment testing phases. For service engagements, request sample builds to validate dimensional accuracy against ISO 2768-mK tolerances before scaling volume.

What Are the Leading Stratasys DMLS Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| Chengdu Yuanhao 3d Technology Co., Ltd. | Sichuan, CN | Prototyping Services (FDM, SLA, PolyJet) | 100.0% | ≤5h | 20% | US $10,000+ | Design, material, finish, labeling, painting |

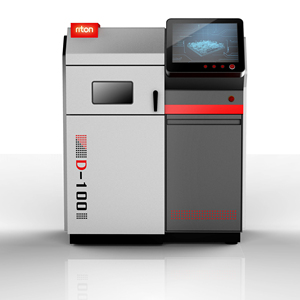

| Guangzhou Riton Additive Technology Co., Ltd. | Guangdong, CN | DMLS/SLM Dental & Industrial Printers | 100.0% | ≤22h | - | - | Limited customization; focus on OEM printer sales |

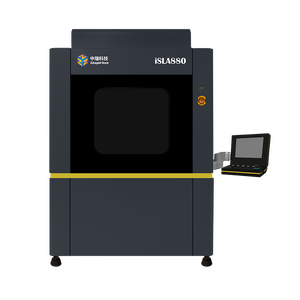

| Shenzhen Jinshi 3d Printing Technology Co., Ltd. | Guangdong, CN | Industrial SLM Machines, Machining Services | 100.0% | ≤9h | - | - | Build size, laser configuration, service integration |

| Guangzhou Rising Dimension Trading Co., Ltd. | Guangdong, CN | Metal 3D Printers (SLM/DMLS), Rapid Prototyping | 100.0% | ≤1h | <15% | US $3,000+ | Custom-built printers, material compatibility |

| Shenzhen Twotrees Technology Co., Ltd. | Guangdong, CN | FDM Printers, Industrial CoreXY Systems | 96.0% | ≤5h | 21% | US $190,000+ | Engraving, color, enclosure, power, labeling |

Performance Analysis

Chengdu Yuanhao and Guangzhou Rising Dimension demonstrate strong responsiveness and full compliance with delivery commitments, making them suitable for time-sensitive prototyping contracts. Shenzhen Jinshi stands out for large-format industrial SLM systems, with offerings priced up to $1.48 million per unit, indicating specialization in high-capacity production environments. Guangzhou Riton focuses on dental DMLS systems, targeting niche medical device manufacturers with complete printer solutions rather than service-based models. Shenzhen Twotrees, while primarily FDM-oriented, shows high reorder activity and robust transaction volume, suggesting reliable execution for entry-level industrial printer procurement. Buyers seeking DMLS-compatible services should prioritize suppliers listing SLM/DMLS-specific product SKUs and proven metal printing infrastructure.

FAQs

How to verify Stratasys DMLS supplier technical competence?

Request evidence of machine specifications, including laser type, scanning speed, and chamber inerting capability. Validate material compatibility with engineering alloys and review sample microstructures or density test reports (ASTM F3303). Confirm post-processing capabilities such as stress relief annealing and surface finishing options.

What is the typical MOQ and pricing range for DMLS printers?

Industrial DMLS/SLM machines typically carry MOQs of 1 set, with prices ranging from $100,000 to over $1.4 million depending on build volume and laser count. Service-based prototyping starts at $0.18 per piece with MOQ of 1 unit, allowing low-volume testing prior to capital investment.

Do suppliers support customization of DMLS equipment?

Yes, select suppliers like Guangzhou Rising Dimension and Shenzhen Jinshi offer custom-engineered SLM systems with tailored build envelopes, multi-laser setups, and automated powder handling. Customization lead times average 60–90 days, with pre-delivery factory acceptance testing recommended.

Are material and process certifications available?

While not all suppliers list ISO or CE certification explicitly, leading vendors provide internal quality control protocols aligned with ISO 9001 standards. Buyers should request process validation documents, including melt pool monitoring logs and part tensile test results, especially for aerospace or medical applications.

What logistics and export support can be expected?

Established suppliers manage international shipping via air or sea freight under FOB or CIF terms. High-value machinery shipments typically include crating, insurance, and customs documentation. Lead times for global delivery range from 15–30 days, depending on destination and import clearance efficiency.