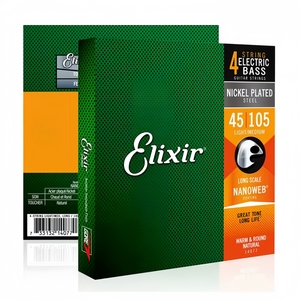

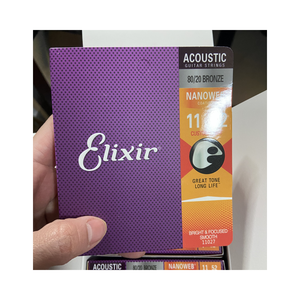

Strings Elixir

1/3

1/3

1/3

1/3

CN

CN

1/1

1/1

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/25

1/25

1/3

1/3

1/3

1/3

1/16

1/16

0

0

1/2

1/2

1/15

1/15

1/3

1/3

1/3

1/3

1/2

1/2

0

0

1/3

1/3

1/3

1/3

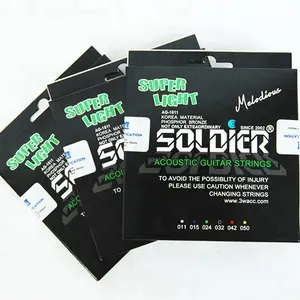

About strings elixir

Where to Find Strings Elixir Suppliers?

No verified suppliers for "strings elixir" are currently available in global manufacturing databases. The term may refer to a branded product line—potentially guitar strings or another specialty stringed instrument component—rather than a standardized industrial category. In the absence of supplier data, sourcing efforts should focus on identifying manufacturers associated with established brands or those producing coated steel/alloy strings for musical instruments.

Historically, regions such as Guangdong and Zhejiang provinces in China serve as primary hubs for musical instrument accessories, hosting vertically integrated facilities capable of drawing, winding, and coating fine-gauge strings. These clusters support precision manufacturing processes including cryogenic treatment, polymer coating application, and automated tension testing, enabling consistent output for corrosion-resistant string products. Without active supplier listings, buyers must rely on indirect sourcing channels, technical specification matching, and brand-authorized distribution networks to procure equivalent-grade products.

How to Choose Strings Elixir Suppliers?

In the absence of direct supplier records, procurement strategies should emphasize verification through technical alignment and quality traceability:

Material & Process Compliance

Confirm use of high-carbon steel or nickel-plated alloys with proprietary polymer coatings designed to inhibit oxidation. Demand documentation on coating adhesion testing (e.g., tape peel tests) and tensile strength validation (ASTM A36/A510 standards). For acoustic consistency, verify batch-level frequency response reports under controlled humidity conditions.

Production Capability Indicators

Evaluate potential partners based on infrastructure benchmarks:

- Minimum 2,000m² dedicated clean-room production space for coating operations

- In-house wire drawing lines with gauge tolerances ≤±0.001mm

- CNC-controlled winding machines with automated defect detection

Cross-reference equipment lists with monthly output capacity (target: 50,000+ sets) and MOQ flexibility (ideally ≤100 units for sampling).

Transaction & Quality Safeguards

Require ISO 9001-certified quality management systems and environmental compliance (RoHS, REACH) for chemical coatings. Utilize third-party inspection services to validate packaging integrity and shelf-life claims (typically 3–5 years for coated strings). Prioritize suppliers offering sample testing under real-world playing conditions before scaling orders.

What Are the Best Strings Elixir Suppliers?

No suppliers are listed in current industrial registries for the keyword "strings elixir." This suggests either exclusive control by a single brand owner or misclassification within broader musical accessory categories. As a result, no comparative performance table can be generated at this time.

Procurement Insight

When sourcing branded or proprietary products like coated strings, consider reverse-engineering specifications to identify contract manufacturers serving major brands. Focus on companies with experience in micro-coating technologies, corrosion resistance R&D, and precision winding. Direct engagement via trade shows (e.g., NAMM Show) or B2B platforms using detailed technical RFQs increases chances of connecting with qualified producers. Verify export history through shipment records indicating past deliveries of HS Code 9209.30 (parts and accessories of musical instruments).

FAQs

How to verify strings elixir supplier reliability?

Without active suppliers, verification depends on tracing manufacturing origins through patent filings, import/export manifests, or authorized distributor disclosures. Cross-check material safety data sheets (MSDS) for coating compounds and audit production sites for adherence to clean-room protocols and waste handling regulations.

What is the average sampling timeline?

For custom-coated string prototypes, expect 20–30 days for formulation, coating trials, and stability testing. Standard samples from existing product lines typically ship within 7–14 days post-approval. Air freight adds 5–8 days for international delivery.

Can suppliers ship strings worldwide?

Yes, once a qualified manufacturer is identified, global shipping is feasible via air or sea freight. Coated strings require climate-stable packaging to prevent moisture exposure. Confirm Incoterms (FOB, CIF) and ensure compliance with destination regulations regarding chemical coatings and labeling requirements.

Do manufacturers provide free samples?

Free samples are uncommon for proprietary or coated products. Most manufacturers charge a nominal fee covering material and labor (typically $20–$50 per set), refundable against future bulk orders exceeding 500 units. Sample policies vary by development stage and IP sensitivity.

How to initiate customization requests?

Submit comprehensive technical briefs including core wire diameter, winding pattern (hex, round), alloy composition, coating thickness (microns), and intended instrument type (acoustic, electric, bass). Reputable producers respond with feasibility assessments, CAD schematics of wound profiles, and projected lifespan data within 5–7 business days.